– 30 –

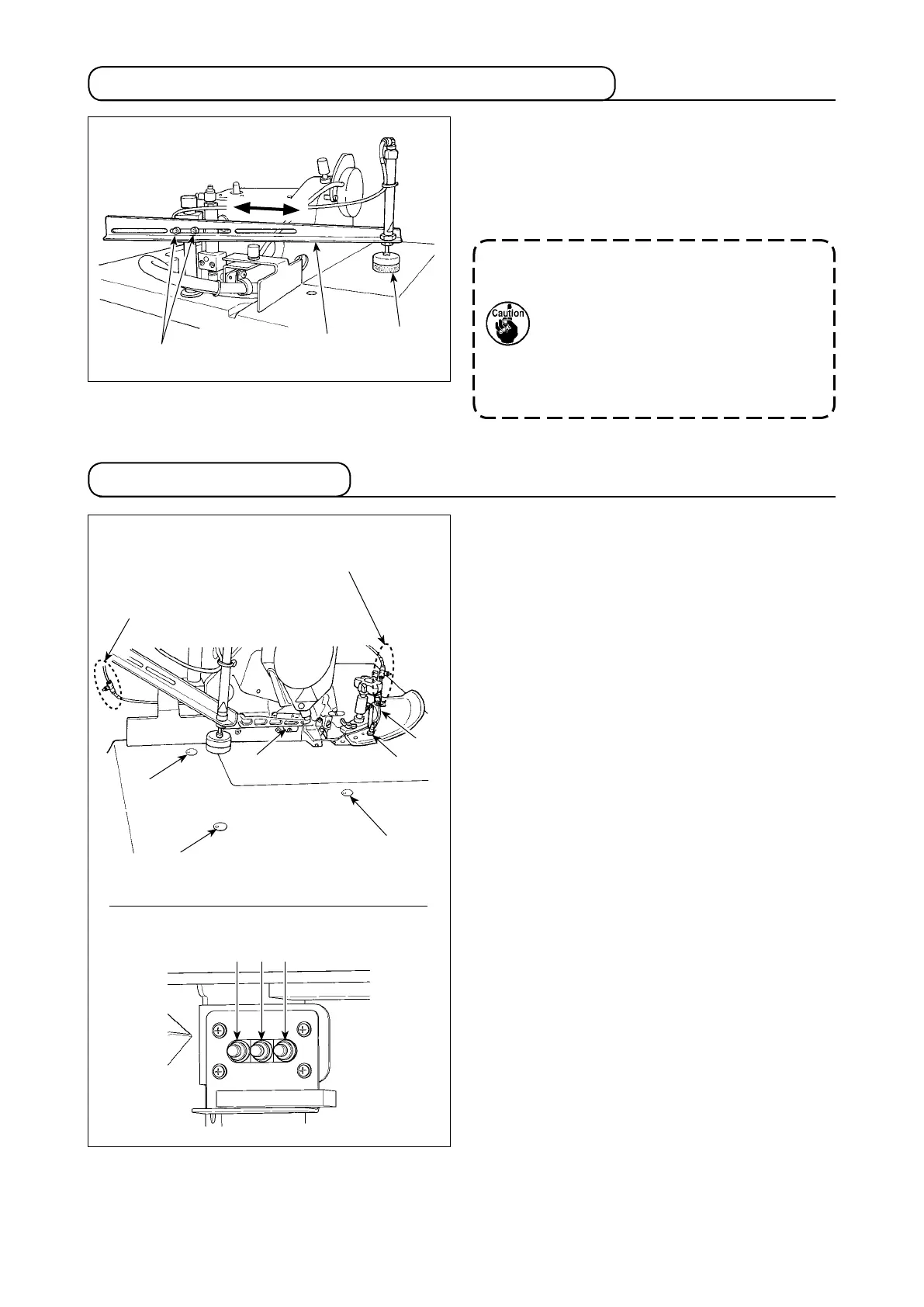

Loosen screws

❷

(at two locations) which x cylin-

der mounting arm

❶

to adjust the arm to the right or

left. Adjust the thread trimmer presser to the position

at which it clamps the material to be sewn at the

center of its width.

6-2.Adjustingthepositionofthethreadtrimmerpresser

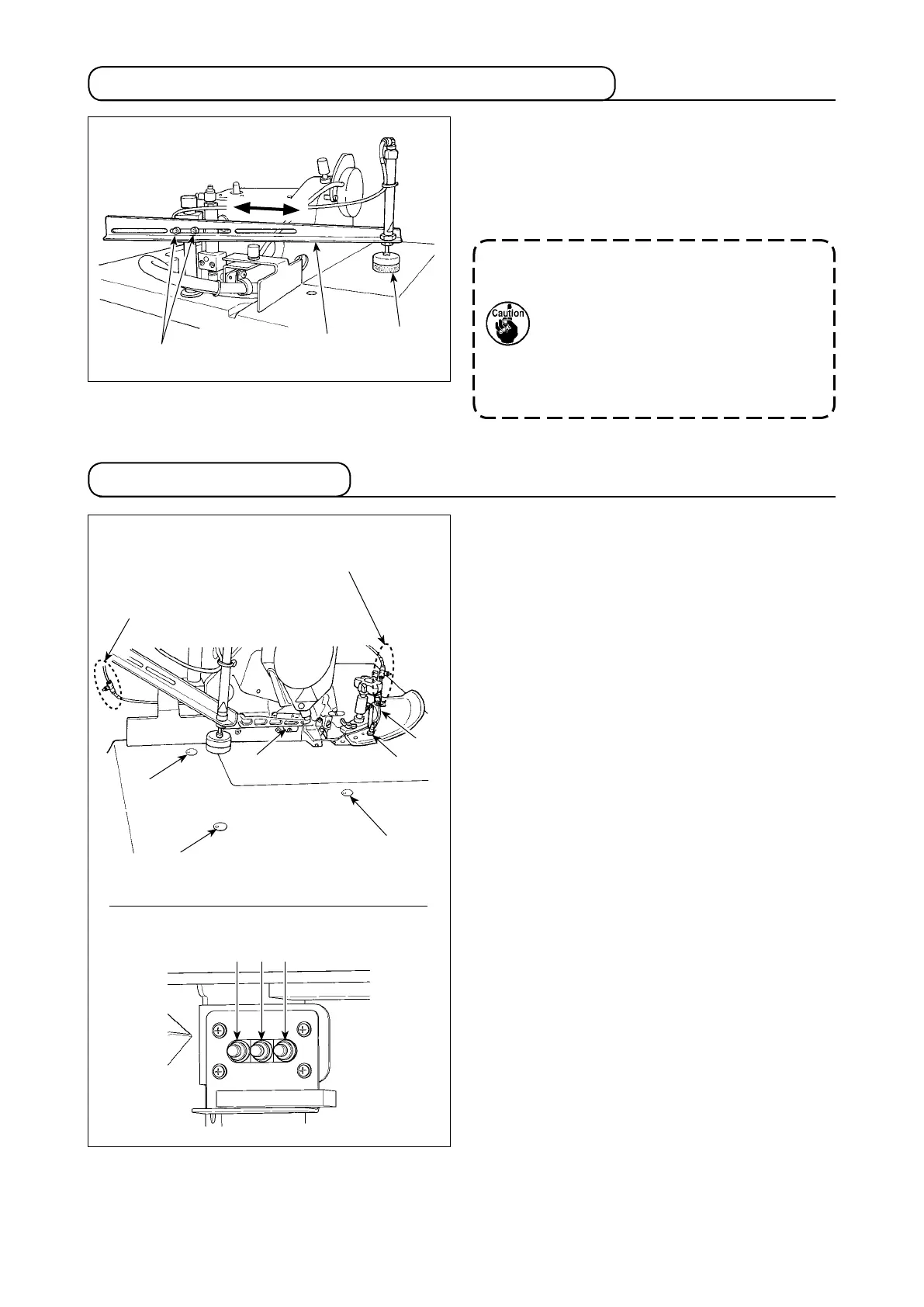

6-3.Adjustingtheairblow

1) The amount of the following air blow should be

adjusted by means of the speed controller ac-

cording to the type of material and pattern to be

sewn.

❶

Cloth feeding air blow

❷

Cloth feeding air blow

❸

Cloth feeding air blow

❹

Side cover air blow

❺

Start sensor air blow

❻

Curve sensor air blow (optional)

2)

The air blowing amount is reduced by turning the

adjusting knob clockwise.

3)

The air blowing direction of the cloth feeding blow

can be changed by loosing the M4 nut mounted

underside of the table.

After changing the air blowing direction, be sure

to tighten the nut to x it. In addition, check to be

sure that the air hoses are fully tightened with a

clip band.

Whenadjusting,xthethreadtrimmer

pressersothatpressersponge

❸

is

alignedwiththetopfaceofthetablewith

thethreadtrimmingcylinderbroughttoits

lower position. If the cylinder is inclined,

the thread trimmer presser may fail to

properly clamp the material or a cylinder

failure can occur.

Forthestartsensorairblow

and curve sensor air blow

Formaterialfeeding

Forthesidecoverairblow

❷

❶

❸

❶

❷

❸

❹

❺

❻

❶ ❷ ❸

Loading...

Loading...