– 44 –

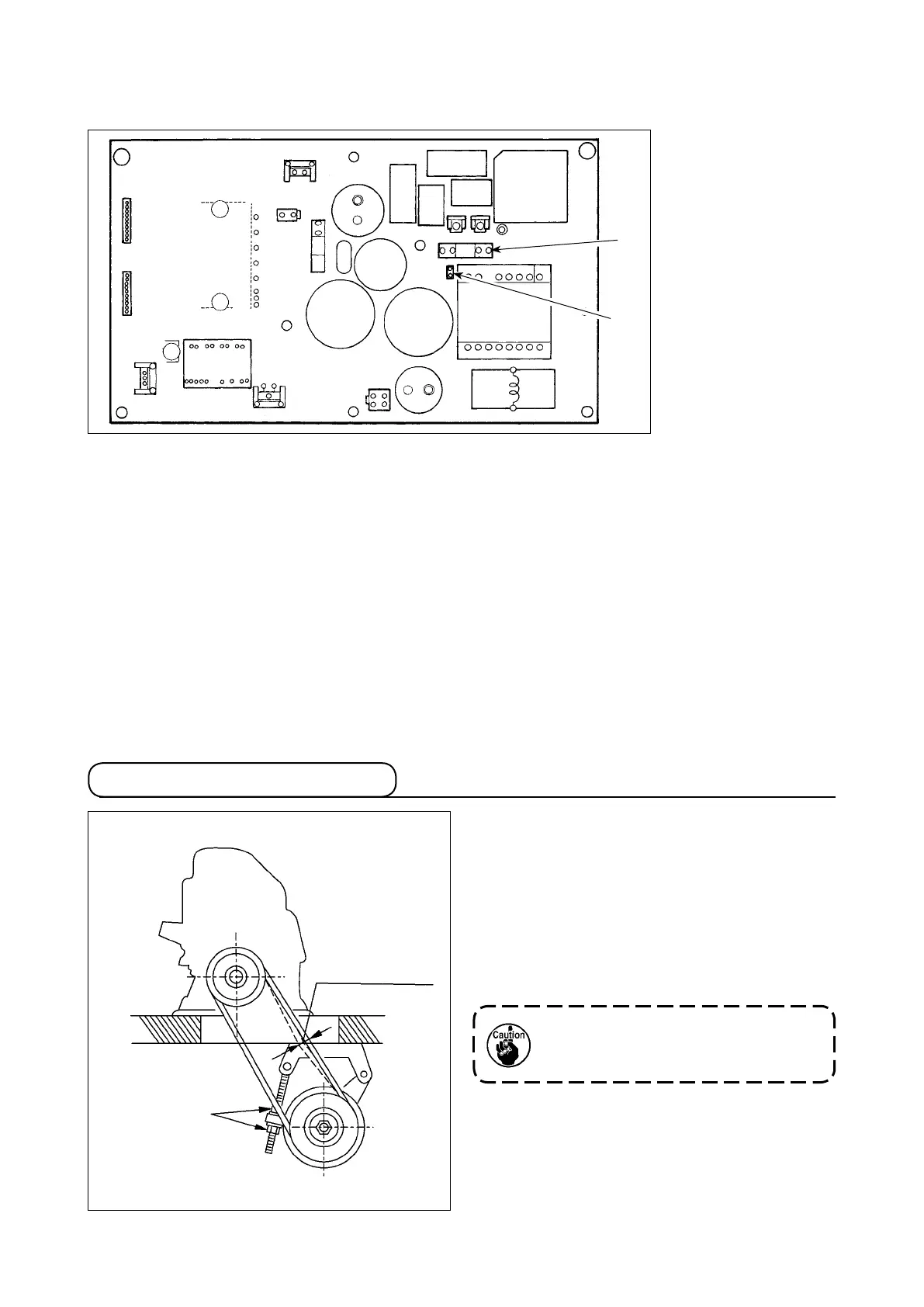

[ReplacingfuseonPWR-Tcircuitboard]

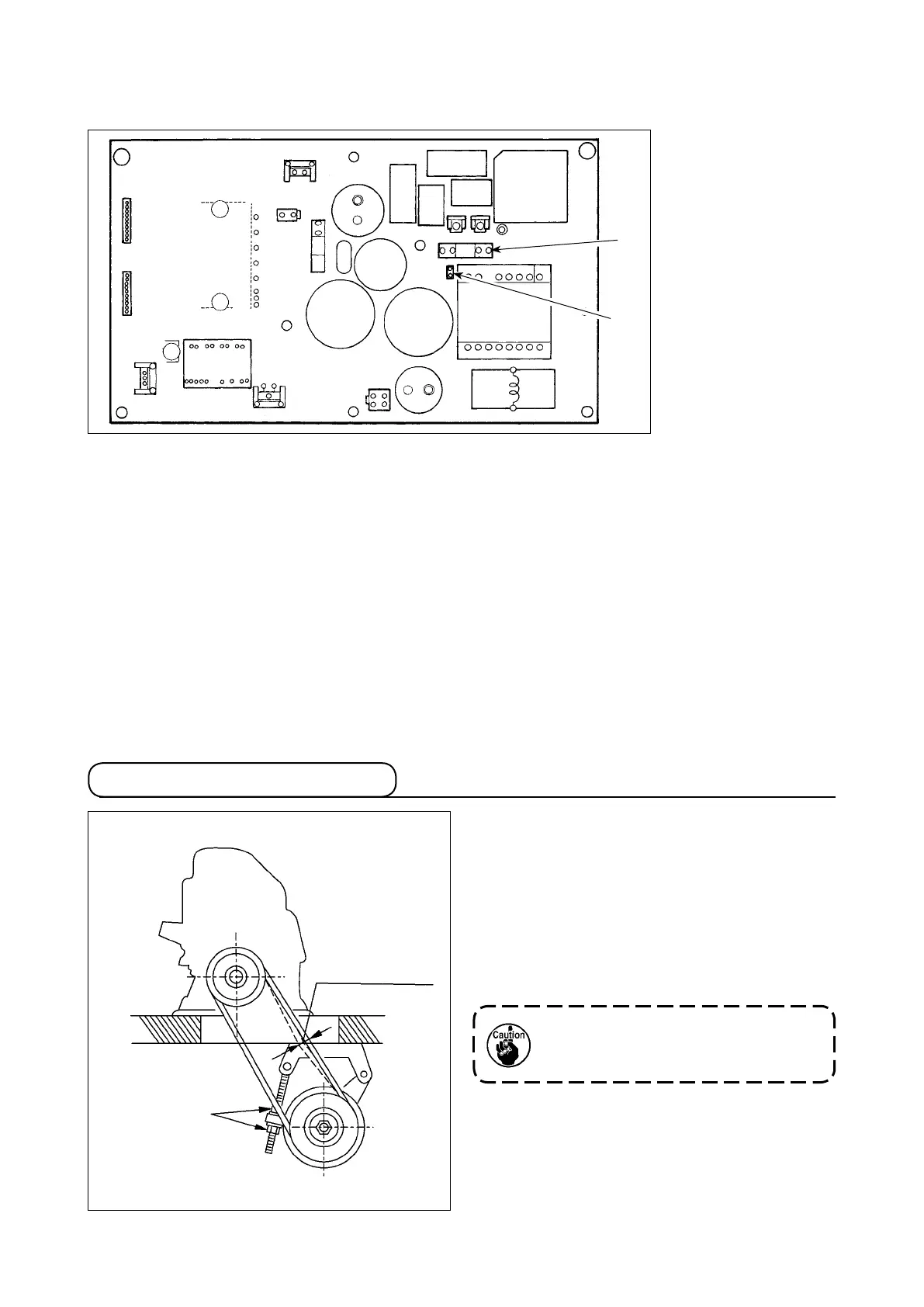

The belt tension should be adjusted by turning the

tension adjust nuts to change height of the motor,

so that the belt sinks down by about 15 mm (9.8N)

when it is depressed by band at the center of the belt

span.

If the belt tension is not adequate, the sewing ma-

chine may not rotate with consistency at the low- to

medium-speed operation.

15mm(9.8N)

Tension

adjust nuts

7-12.Adjustingthebelttension

Thebeltcanincreaseinlengthasaresult

ofuse.Besuretoperiodicallycheckand

adjust the belt tension appropriately.

(Caution)TheillustrationbelowshowsthePWR-TPCB.ThetypeofPCBdiffersbydestination.

❺

❻

6) Holding the glass section of fuse

❺

, remove the fuse.

(Caution) Thereisariskofelectricalshockwhenremovingthefuse.BesuretoremovethefuseafterLED

❻

hastotallygoneout.

5) Be sure to use a fuse with the designated capacity.

❺

: 3.15 A/250 V Time-lag fuse

(Power circuit protective fuse)

Part number: KF000000080

8) Install the control box to the motor.

9) Connect all the cables to the control box. (Refer to

"7-13.Destinationofconnectionforinput/output

connectors" p.45.)

Loading...

Loading...