– 40 –

7-7.Cautionsforthecompressedairsupply(sourceofsupplyair)facility

As large as 90 % of failures in pneumatic equipment (air cylinders, air solenoid valves) are caused by "con-

taminated air."

Compressed air contains lots of impurities such as moisture, dust, deteriorated oil and carbon particles. If

such "contaminated air" is used without taking any measures, it can a cause of troubles, inviting reduction in

productivity due to mechanical failures and reduced availability.

Be sure to install the standard air supply facility shown below whenever the machine provided with pneumat-

ic equipment is used.

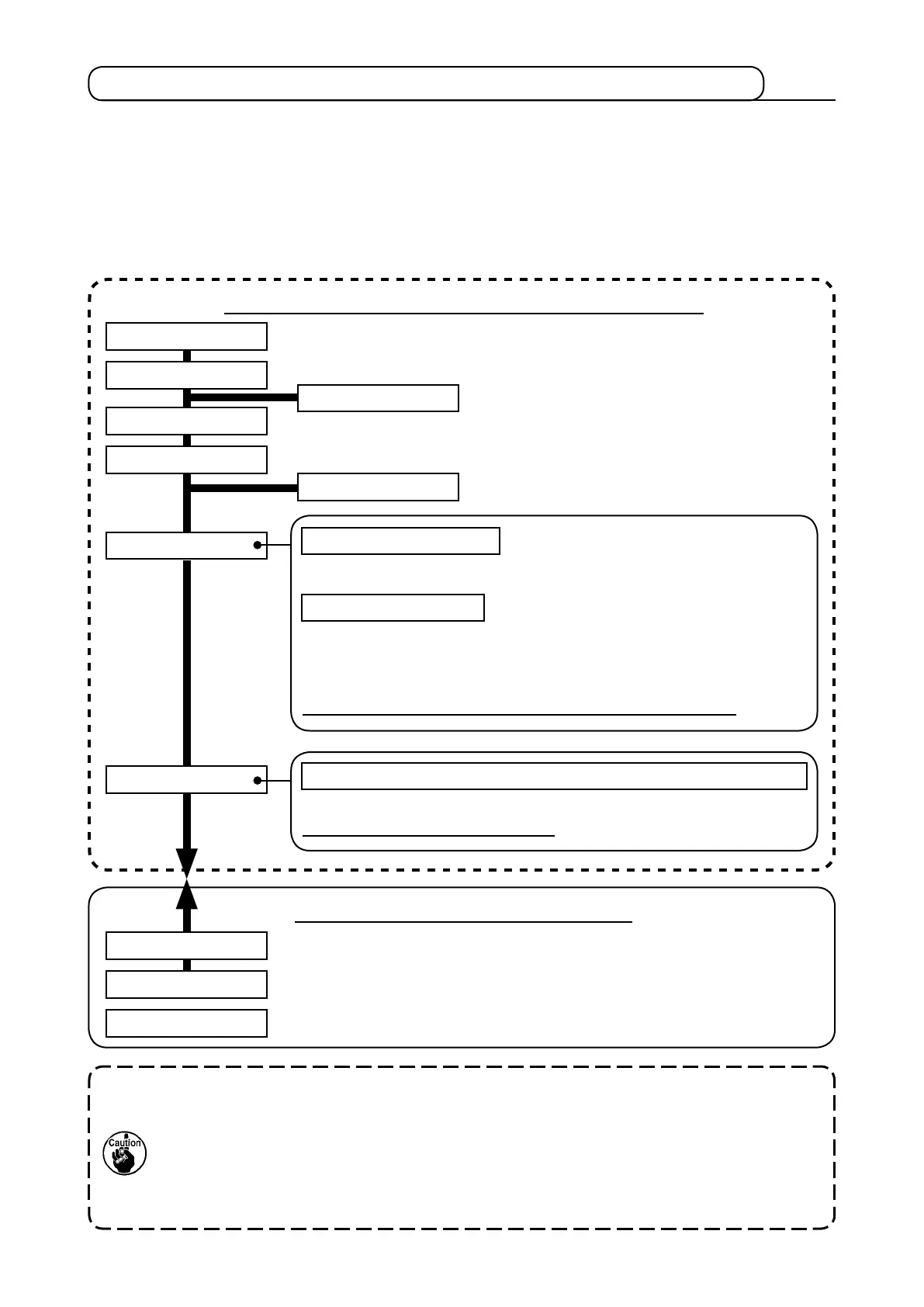

Standardairsupplyfacilitytobepreparedbytheuser

StandardequipmentsuppliedbyJUKI

Air compressor

After cooler

Airtank

Mainlinelter

Air dryer

Mistseparator

Auto-drain

Auto-drain

Quality of the air supply

When the supply air contains a considerable amount of moisture

Ambient environment

When our machine is installed at a place where the temperature greatly

changes in the morning and in the evening from that in the daytime or

freeze is like to occur

In the aforementioned cases, be sure to install an air dryer.

(Most troubles in the air solenoid valves are caused by carbon.)

Be sure to install a mist separator.

When the supply air contains a considerable amount of carbon and dust

Filterregulator

Air solenoid valve

Air cylinder

Cautionsformainpiping

• Besuretoslopemainpipingbyafallinggradientof1cmper1minthedirectionofairow.

• Ifthemainpipingisbranchedoff,theoutletportofthecompressedairshouldbeprovidedatthe

toppartofthepipingusingateeinordertopreventdrainsettlinginsidethepipingfromowing

out.

• Auto drains should be provided at all lower points or dead ends in order to prevent the drain from

settlinginthoseparts.

Loading...

Loading...