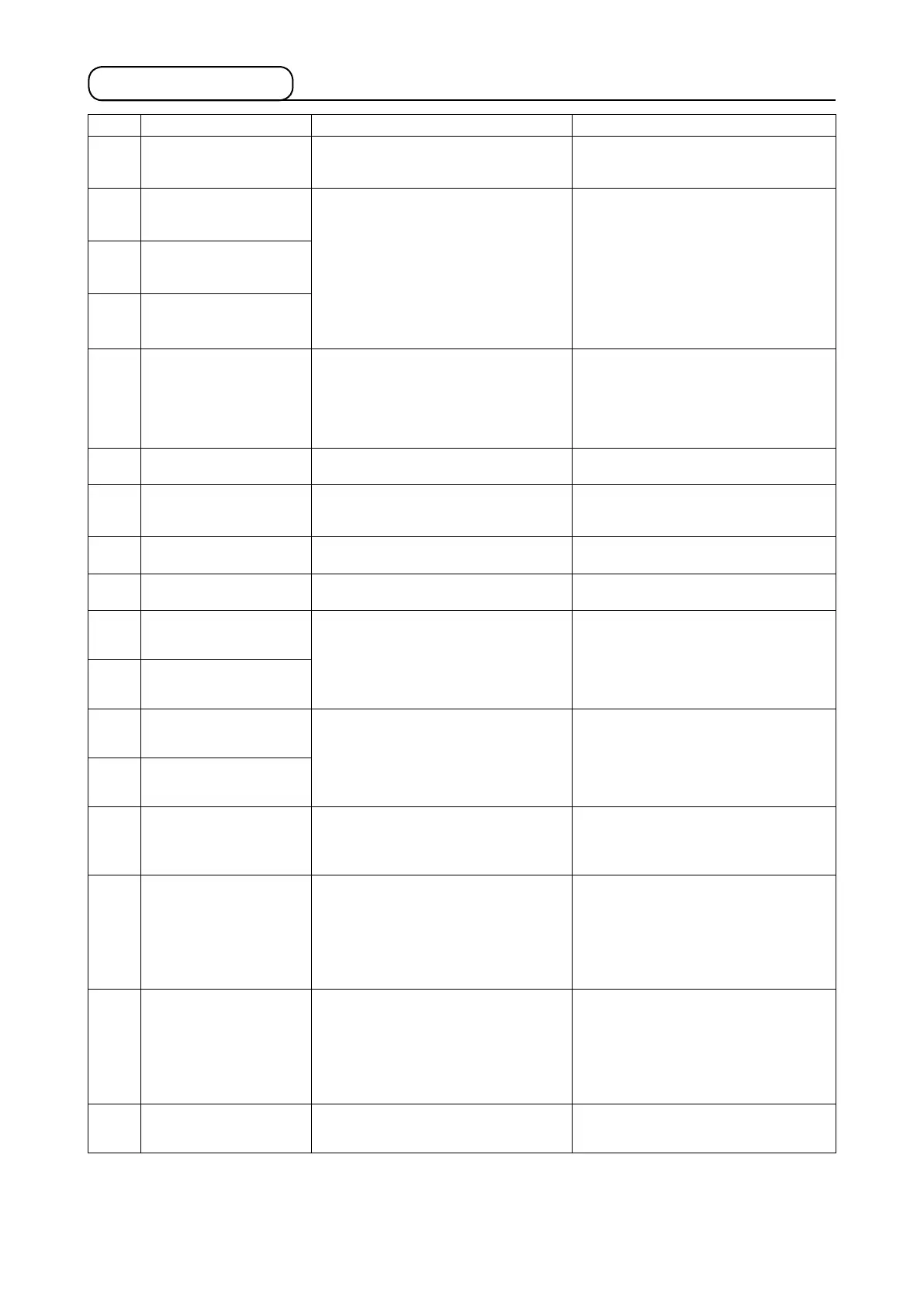

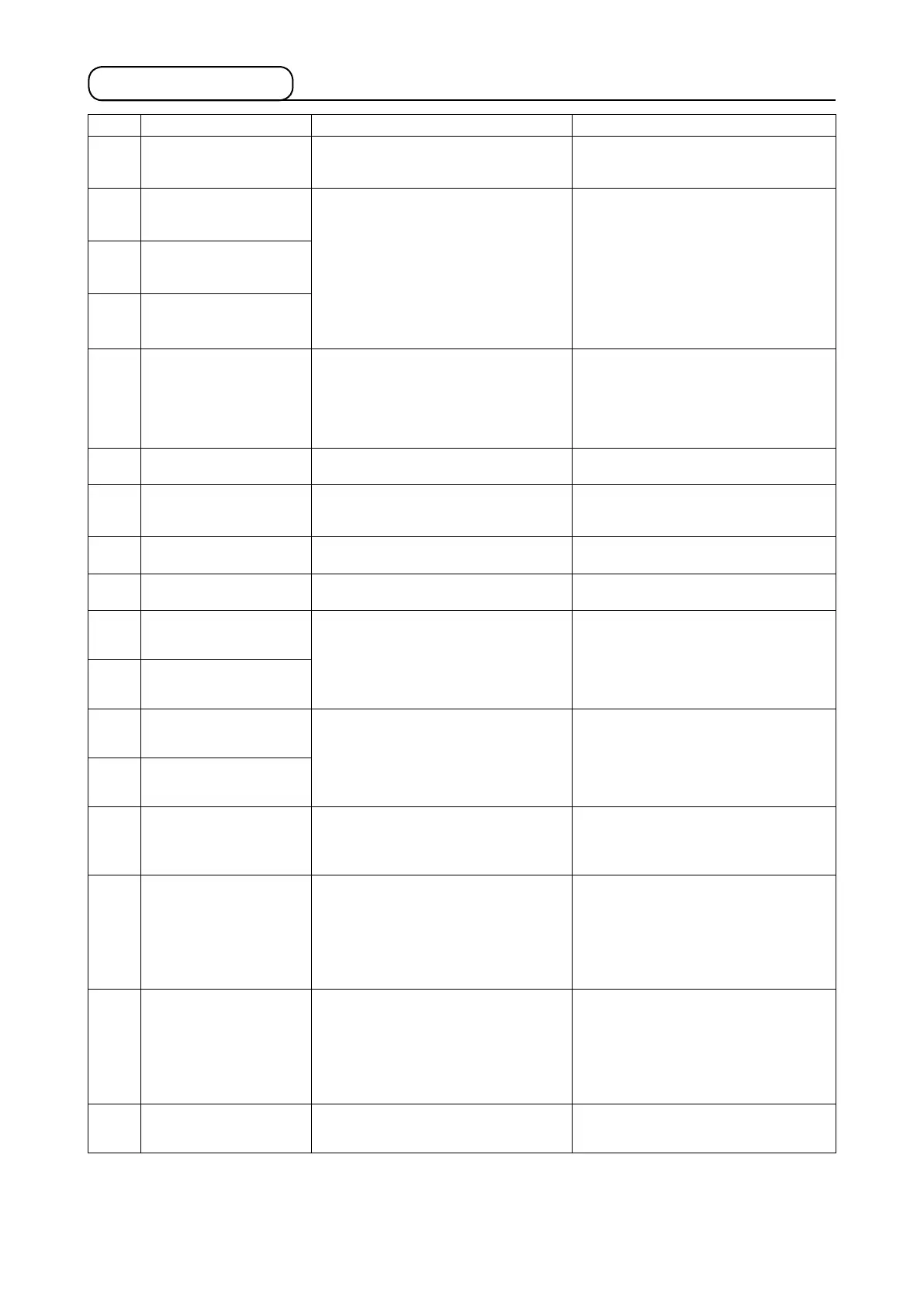

– 47 –

7-15.Errorcodelist

No.

Descriptionoferrordetected

Causeofoccurrenceexpected Itemstobechecked

E000

Execution of data initialization

(This is not the error.)

• When the machine head is changed.

• When the initialization operation is execut-

ed.

E003 Disconnection of synchro-

nizer connector

• When position detection signal is not input

from the sewing machine head synchro-

nizer.

• When the synchronizer has broken.

• Belt is loose.

• Machine head is not proper.

• Motor pulley is not proper.

• Check the synchronizer connector (CN33,

CN43) for loose connection and discon-

nection.

• Check whether the belt is loose.

• Check whether the synchronizer cord has

broken since the cord is caught in the ma-

chine head.

• Check the belt tension.

• Check the setting of the machine head.

• Check the setting of the motor pulley.

E004 Synchronizer lower position

sensor failure

E005 Synchronizer upper position

sensor failure

E007 Overload of motor

• When the machine head is locked.

• When sewing extra-heavy material beyond

the guarantee of the machine head.

• When the motor does not run.

• Motor or driver is broken.

• Check whether the thread has been entan-

gled in the motor pulley.

• Check the motor output connector (4P) for

loose connection and disconnection.

• Check whether there is any holdup when

turning the motor by hand.

E050 The pause switch is

pressed

• The connector of the switch has come off. • Check the connector of the pause switch

for loose connection and disconnection.

E070 Slip of belt

• When the machine head is locked.

• Belt is loose.

• Check whether there is any holdup when

turning the motor by hand.

• Check the belt tension.

E071 Disconnection of motor

output connector

• Disconnection of motor connector • Check the motor output connector for loose

connection and disconnection.

E302 Opening of the cloth plate

is detected.

• The cloth plate is not installed on the table. • Check whether the cloth plate is set on the

table

E333 The material is inserted on

the start sensor.

• Dust on the sensor

• Sensitivity of the sensor

• Dust around the sensor

• Adjustment of the sensitivity of the sensor.

• Setting of the L/D

E334 The material is inserted on

the curve sensor.

E730 Encoder failure

• When the motor signal is not properly

inputted.

• Check the motor signal connector (CN30)

for loose connection and disconnection.

• Check whether the motor signal cord has

broken since the cord is caught in the ma-

chine head.

E731 Motor hole sensor failure

E733 Inverse rotation of motor

• This error occurs when the motor is run-

ning at 500 rpm or more in the opposite di-

rection of that of rotation indication during

motor is running.

• Connection of the encoder of main shaft

motor is wrong.

• Connection for the electric power of main

shaft motor is wrong.

E811 Overvoltage

• When voltage higher than guaranteed one

is inputted.

• 220V has been inputted to SC-510 of 110V

specications.

• 400V is applied to the box of 220V (230V).

• Check whether the applied power voltage

is higher than the rated voltage + (plus)

10% or more.

• Check whether 110V/220V changeover

switch is improperly set.

In the aforementioned cases, POWER p.c.b

is broken.

E813 Low voltage

• When voltage lower than guaranteed one

is inputted.

• 110V has been inputted to SC-510 of 220V

specications.

• 110V is applied to the box of 220V.

• Inner circuit is broken by the applied over-

voltage.

• Check whether the voltage is lower than

the rated voltage – (minus) 10% or less.

• Check whether 110V/220V changeover

switch is improperly set.

• Check whether fuse or regenerative resis-

tance is broken.

E924 Motor driver failure

• Motor driver has broken.

Loading...

Loading...