o Whenthe SC-220panel is used, when pattern No. 3 is selected the number

of

stitches for start reverse

stitching and

finish

reverse

stitching isindicated. 4

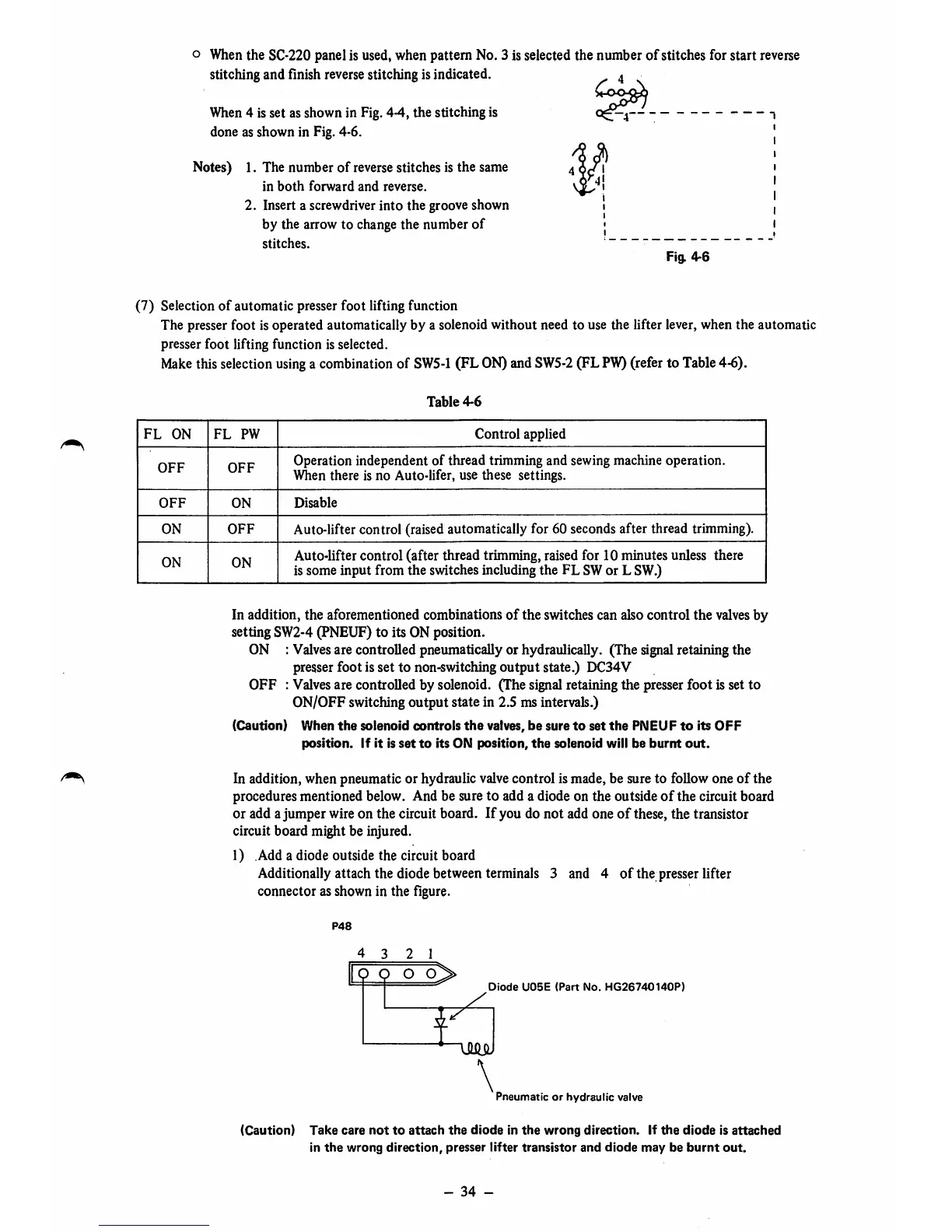

When4 is set as shown in Fig.

44,

the stitching is

done as shown in Fig. 4-6.

Notes) 1. The number of reversestitches is the same

in

both

forward

and

reverse.

2. Insert a screwdriverinto the groove shown

by the arrow to changethe number of

stitches.

Fig. 4-6

(7)

Selection

of

automatic presser foot lifting function

The presser foot is operated automatically by a solenoid without need to use the lifter lever, when the automatic

presser foot lifting function is selected.

Make

thisselection

using

a combination of

SW5-1

(FL ON)and

SW5-2

(FL

PW)

(referto Table4-6).

Table

4-6

FL

ON

FL

PW

Control applied

OFF

OFF

Operation independent

of

thread trimming and sewing machine operation.

When there is no Auto-lifer, use these settings.

OFF

ON

Disable

ON

OFF

Auto-lifter control (raisedautomatically for 60 secondsafter thread trimming).

ON

ON

Auto-lifter control (after thread trimming,raisedfor 10 minutes unless there

is some input from the switches including the FL SWor L SW.)

In addition, the aforementioned combinations of the switches can also control the valvesby

setting SW2-4(PNEUF) to its ON position.

ON : Valvesare controlled pneumatically or hydraulically. (The signalretaining the

presser foot is set to non-switching

output

state.) DC34V

OFF : Valvesare controlled by solenoid. (The signal retaining the presser foot is set to

ON/OFF switchingoutput state in 2.5 ms intervals.)

(Caution) When

the

solenoid controls

the

valves, be sure

to

set

the

PNEUF

to

its

OFF

position.

If it is

set

to

its ON

position,

the

solenoid

will

be

burnt

out.

In addition, when pneumatic or hydraulic valvecontrol is made, be sure to follow one

of

the

procedures mentioned below. And be sure to add a diode on the outside

of

the circuit board

or add a jumper wire on the circuit board.

If

you do

not

add one

of

these, the transistor

circuit board might be injured.

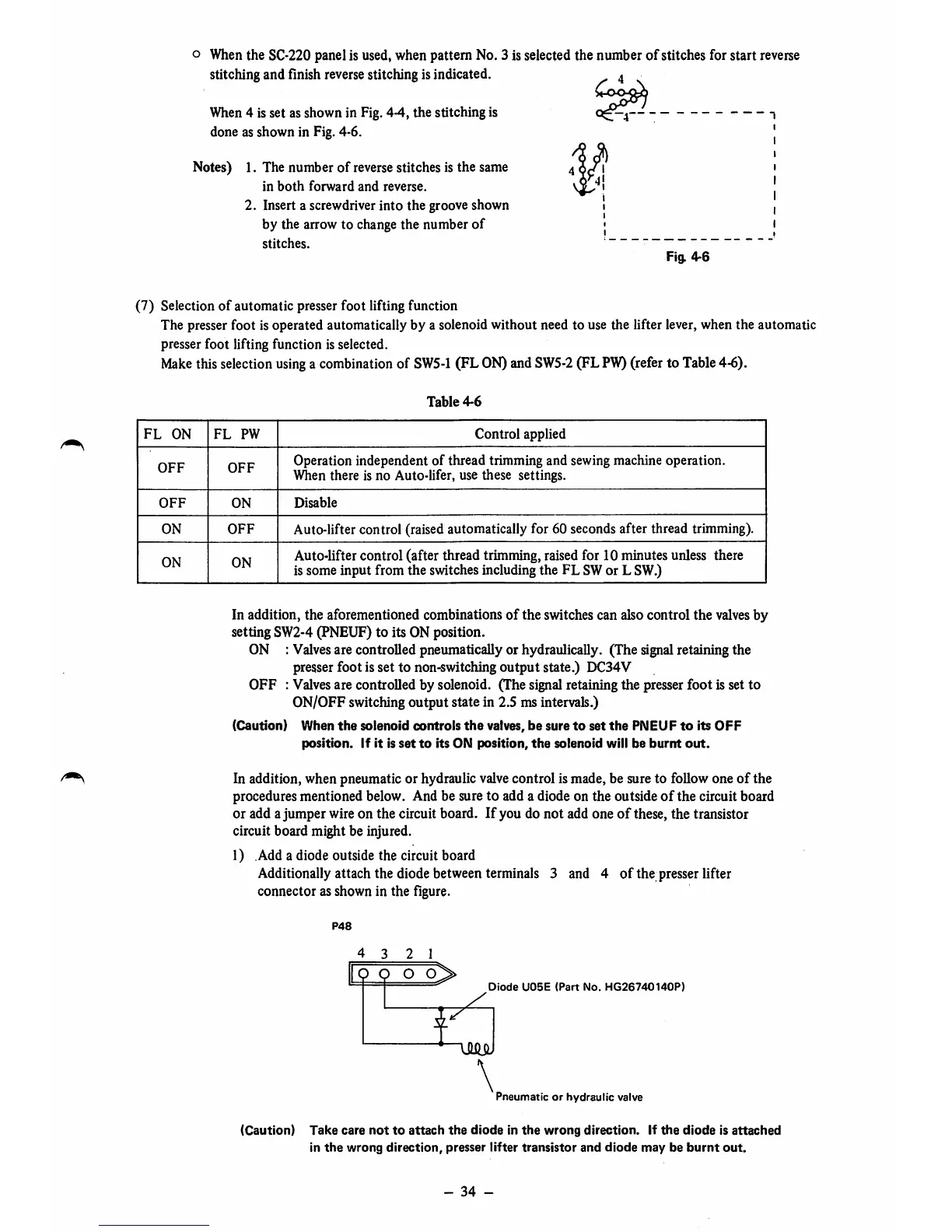

1) Add a diode outside the circuit board

Additionallyattach the diode between terminals 3 and 4

of

the presserhfter

connector as shown in the figure.

P48

4 3 2 1

Q O O O

Diode

U05E

(Part

No.

HG26740140P)

7

i

\

Pneumatic

or

hydraulic

valve

(Caution)

Take

care

not

to

attach

the

diode

in

the

wrong

direction,

if

the

diode

is

attached

in

the

wrong

direction,

presser

lifter

transistor

and

diode

may

be

burnt

out.

-

34

-

Loading...

Loading...