1.

GENERAL

1-1.

Features

1)

Use

ofan

AC

servomotor

provides

the

following

mqor

advantages:

(1) No noise or vibration while the machine is at rest.

(2)

The

power

consumption

is

40%

to

60%

compared

with

the

conventional

power

consumption.

(3)

The

motor

weight

has

been

almost

halved,

permitting

easier

layout

change.

(4)

The

absence

ofa

clutch

(no

brake

in

case

ofN

company's

motor)

makes

theunit

virtually

maintenance-fiee.

(H

company's

brake

is

good

for

more

than 10

years

under

normal

operation.)

Unlike the DC servomotor, there is no bmsh.

2) Pedal operation features

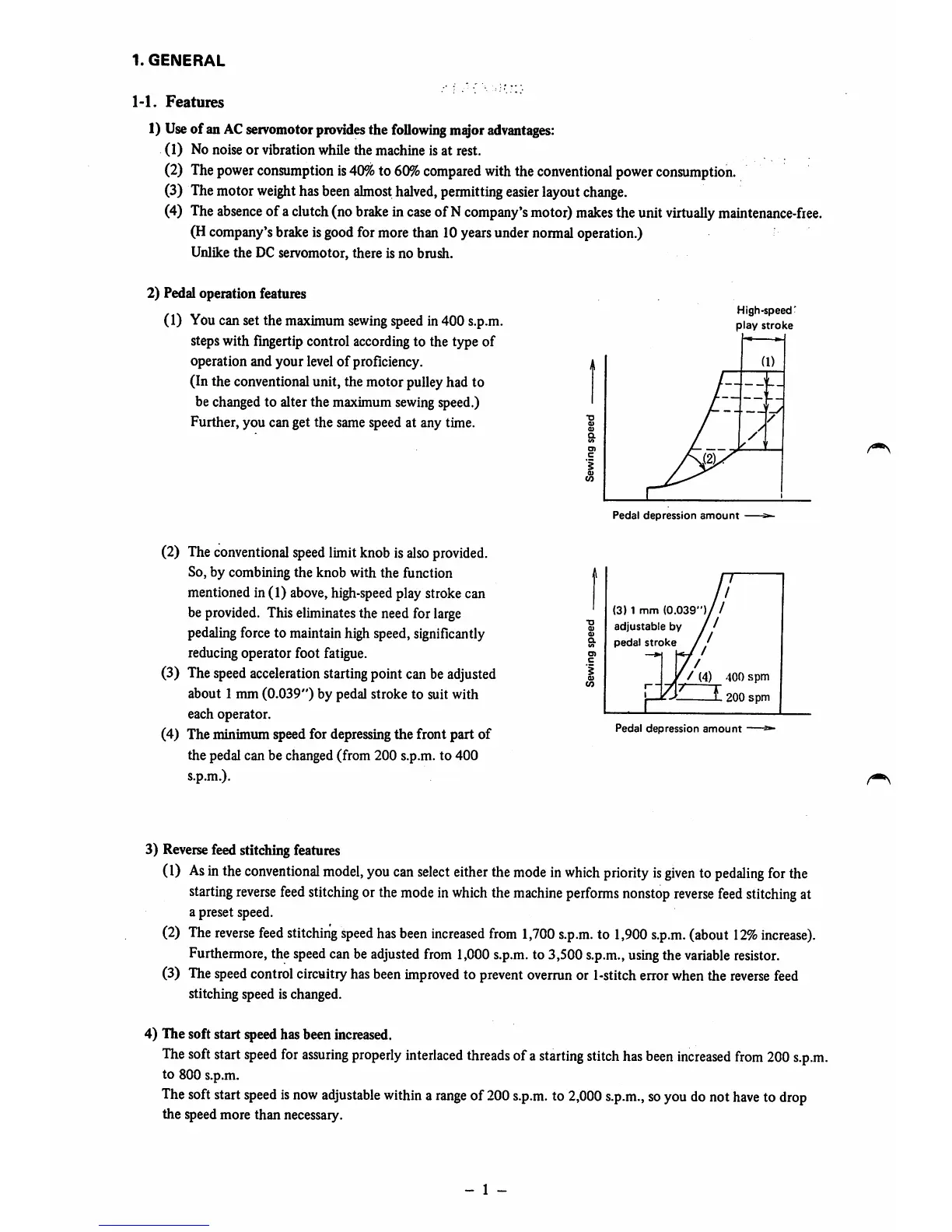

(1) Youcanset the

maximum

sewing

speed

in400

s.p.m.

stepswith fingertipcontrol according to the type of

operation and your level

of

proficiency.

(In the conventional unit, the motor pulleyhad to

be changedto alter the maximum

sewing

speed.)

Further, you can get the samespeedat any time.

(2) The

conventional

speed

limit

knobis

also

provided.

So, by combining the knob with the function

mentioned in(1)

above,

high-speed

play strokecan

be provided. This eliminatesthe need for large

pedalingforce to maintain high speed,significantly

reducing operator foot fatigue.

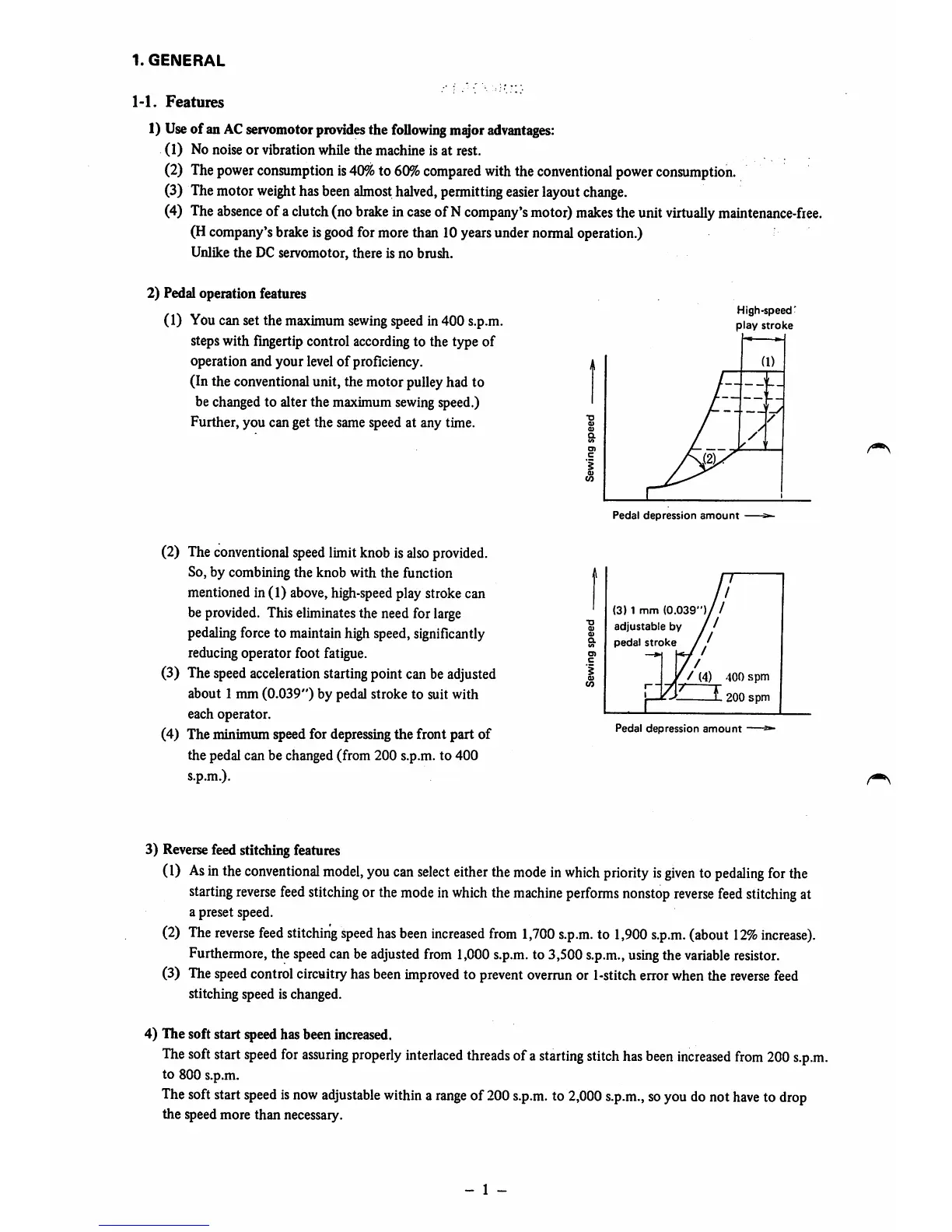

(3) The

speed

acceleration

starting

pointcanbe

adjusted

about 1 mm (0.039") by pedal stroke to suit with

each operator.

(4) The minimum speedfor depressing the front part of

the pedal can be changed(from 200 s.p.m. to 400

s.p.m.).

High-speed'

play

stroke

Pedal

depression

amount

(3)

1mm

(0.039

'l

adjustable

by

^

pedal

stroke

>

/

/ (4) 400 spm

_t

200

spm

Pedal

depression

amount

3)

Reverse

feedstitchingfeatures

(1)

As

in

the

conventional

model,

you

can

select

either

the

mode

in

which

priority

is

given

to

pedaling

for

the

starting

reverse

feed

stitching

or the

mode

in

which

the

machine

performs

nonstop

reverse

feed

stitching

at

a preset speed.

(2)

The

reverse

feed

stitching

speed

has

been

increased

from

1,700

s.p.m.

to

1,900

s.p.m.

(about

12%

increase).

Furthermore, the

speed

canbe

adjusted

from

1,000

s.p.m.

to 3,500

s.p.m.,

using

the

variable

resistor.

(3)

The

speed

control

circuitry

has

been

improved

to

prevent

overrun

or

1-stitch

error

when

the

reverse

feed

stitching speed is changed.

4) The softstart speedhasbeen

increased.

The

soft

start

speed

for

assuring

properly

interlaced

threads

ofa

starting

stitch

has

been

increased

from

200

s.p.m.

to 800 s.p.m.

The

soft

start

speed

is

now

adjustable

within

a

range

of

200

s.p.m.

to

2,000

s.p.m.,

so

you

do

not

have

to

drop

the speed more than necessary.

- 1 -

Loading...

Loading...