5-2. Memorybattery chargingmonitor LED(SC-320 only)

Zf n

i-

u

Fig.

5-10

o

If the sewingmachineis not operated for a long time, it can

lose charge,and LED 1may light.

When the LED lights, all the patterns in internal memory

are

lost.

If necessary, set the memory again.

However, this does

not

cause trouble in sewing, so continue

to

work.

<

For

reference

>

1. Time required to charge.

4 ~ 5 hours (enough for one day

of

operation)

2. Backup

period

Since semiconductors are used, the backup period varies according to the operating conditions.

It

is calculated as follows;

Standard : apprbx. 600 days

Worst case : approx. 6 days

Judging from the above results, the backup should last more than three months in an ordinary location.

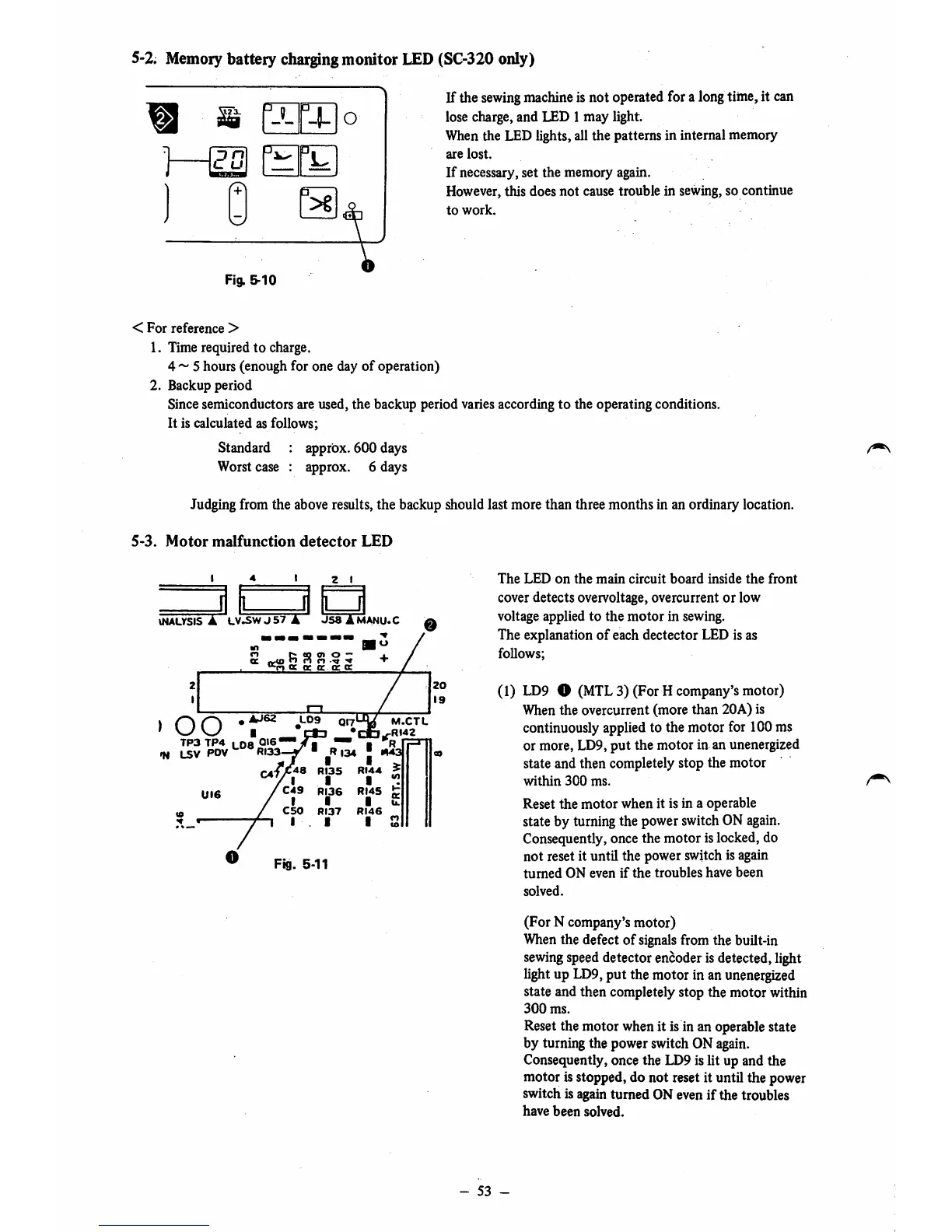

5-3.

Motor

malfunction

detector

LED

INALYSIS A

LV.SW

J

57

A

JU6Z

I

TP3

TP4

1

08

LSV POV

J58

AMANU.C

M.CTL

PI46

The

LED

on

the

main

circuit

board

inside

the

front

cover detects overvoltage, overcurrent or low

voltage applied to the motor in sewing.

The explanation

of

each dectector LED is as

follows;

(I)

LD9

O

(MTL

3) (For H company's motor)

Whenthe overcurrent (more than 20A) is

continuouslyappliedto the motor for 100ms

or more, LD9,put the motor in an unenergized

state and then completely stop the motor

within

300

ms.

Reset the

motor

when it is in a operable

state by turningthe power switchON

again.

Consequently, once the motor islocked,do

not reset it until the power switch is again

turned

ON

even

if

the

troubles

have

been

solved.

(For N company's motor)

Whenthe defect of signalsfrom the built-in

sewing

speeddetector encoder is detected, light

lightup LD9,put the motor in an unenergized

state and then completely stop the motor within

300

ms.

Reset the motor whenit is in an operablestate

by turning the power switch ON again.

Consequently,once the LD9 islit up and the

motor is stopped, do not reset it until the power

switch is again turned ON even if the troubles

have

been

solved.

-

53

-

Loading...

Loading...