7

1 Introduction

1.1 Description

The controller series consists of four freely programmable instruments in different DIN

formats for controlling temperature, pressure and other process variables.

As a temperature controller TR

1

according to EN 14597 the devices are used in heat-

generating plants to control the temperature of liquids or gases (mode of action: 1B).

The high-contrast, multicolor LCD display for process value, setpoint and operator

prompting contains two four-digit 7-segment displays, two single-character 16-

segment displays, display of the active setpoints, six status indicators, and displays

for the unit, ramp function and manual operation.

Just four keys on the front panel are needed for operation, parameterization and

configuration. The instruments can be used as 2-state, 3-state, modulating or

continuous controllers. The controller software includes a program or ramp function,

parameter set changeover, two autotuning (self-optimization) procedures, a math and

logic module, as well as 4 limit comparators.

Linearizations for the usual transducers are stored, and a customer-specific

linearization table can be programmed.

A setup program is available for user-friendly configuration from a PC.

An RS422/485 or a Profibus-DP interface can be used to integrate the instrument into

a data network.

The electrical connection is made at the back of the instrument, via screw terminals.

1. For more detailed explanation, see EN 14597

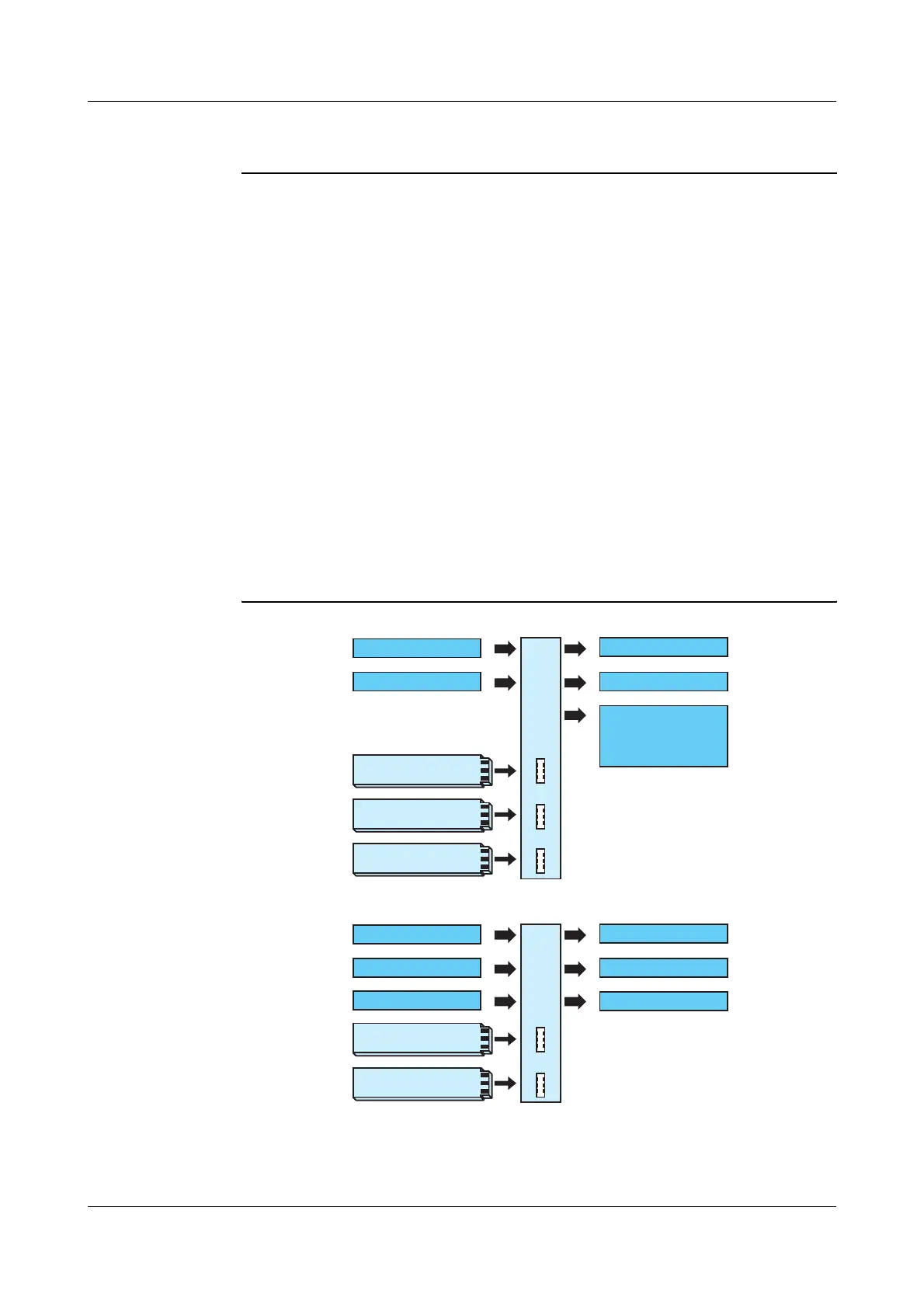

Analog input

Option 1

Option 2

2 binary inputs

2 relays (changeover)

2 logic outputs

Supply voltage

17 V / 20 mA

for 2-wire

transmitter

Type 703042/43/44

Option 3

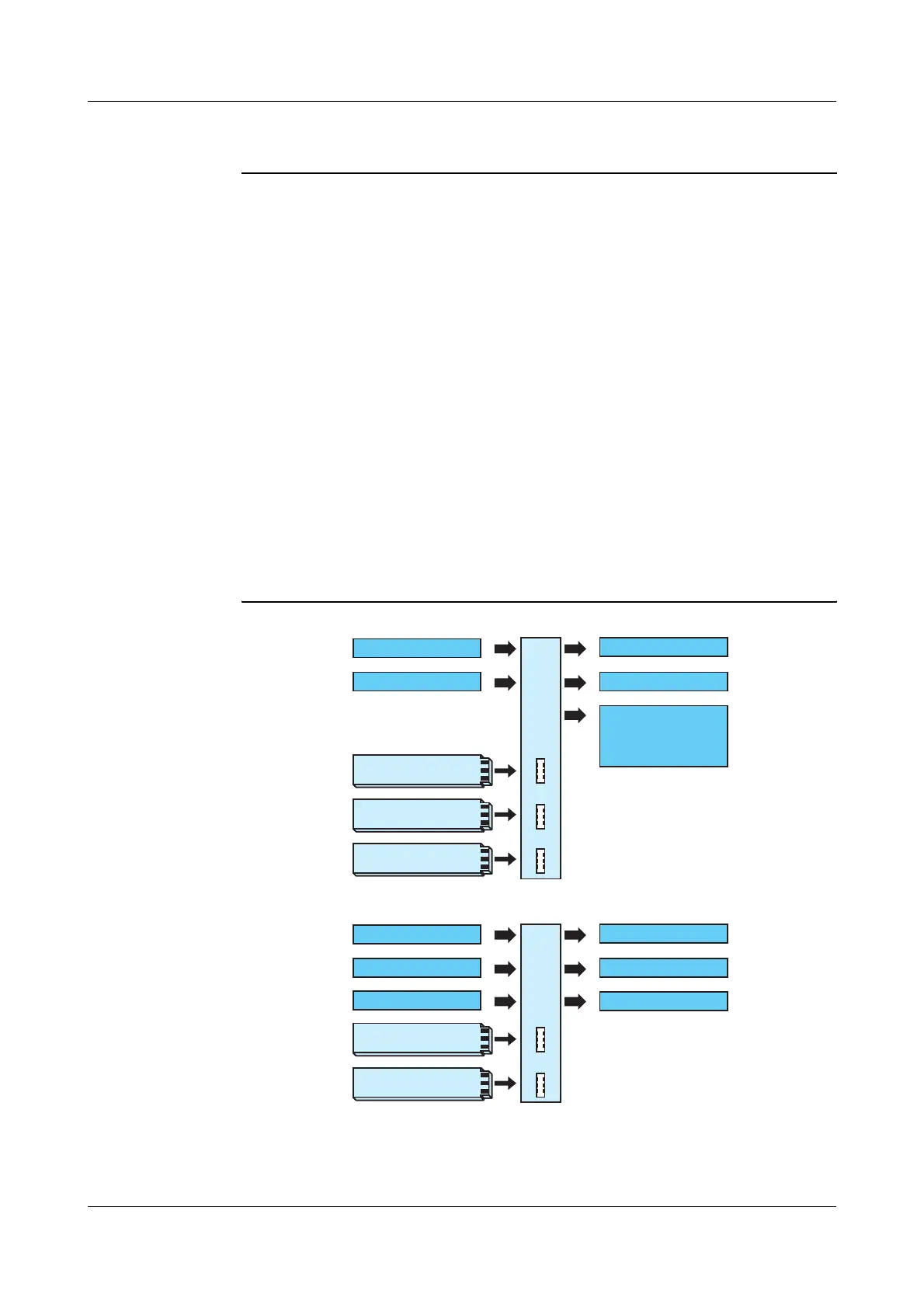

Analog input

Option 1

Option 2

Binary input

Binary input

2 relays (make)

Logic output

Logic output

or

or

Type 703041 (48mm x 48mm)

Loading...

Loading...