7.4 Setting the Overload Protection Cut-Out

In the star-delta configuration the phase current is fed via the overload protection cut-out. This phase

current is 0.58-times the rated motor current (see nameplate in the control cabinet).

To prevent the overload protection cut-out from being triggered by voltage fluctuations, tem‐

perature influences or component tolerances, the setting can be higher than the calculated

phase current.

➤ Set up the overload protection cut-out.

The overload cut-out drops out despite being correctly set?

➤ Contact authorized KAESER Service representative.

7.5 Setting the Motor Overload Protection Switch

In direct on-line starting, the current for the fan motor is fed via the motor overload protection switch.

To prevent the overload protection switch from being triggered by voltage fluctuations, temper‐

ature influences or component tolerances, the setting can be higher than the motor rated current

(see motor nameplate).

➤ Check the motor overload protection switch setting.

The overload switch shuts the machine down despite being correctly set?

➤ Contact KAESER Service representative.

7.6 Pouring Cooling Oil into the Airend

Before starting the compressor for the very first time and before re-starting after a shutdown period

of more than 3 months it is necessary to pour a quantity of cooling oil into the airend.

A label showing the type of oil used is found near the oil separator tank filling port.

➤ Use the same type of oil.

Material 1.1 quart Cooling oil

Precondition The power supply disconnecting device is switched off.

The disconnecting device is locked in the off position.

A check has been made that no voltage is present.

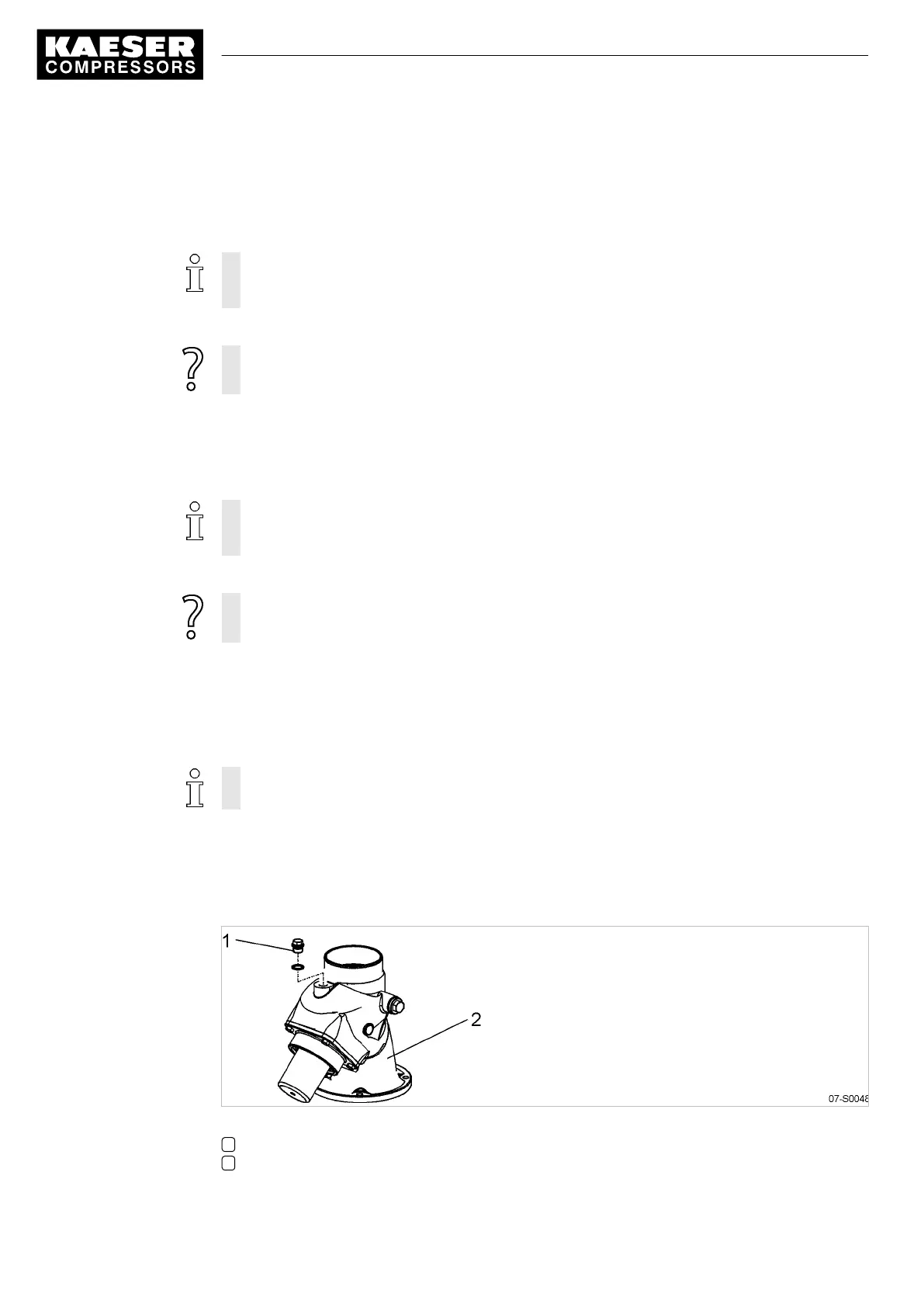

Fig. 16 Inlet valve filling port

1 Screw plug

2 Inlet valve

7 Initial Start-up

7.4 Setting the Overload Protection Cut-Out

42

Service Manual Screw Compressor

ASD T Tri-Voltage 9_5721 06 USE

Loading...

Loading...