➤ Keep a log of all maintenance and repair work.

This enables the frequency of individual maintenance tasks and deviations from our recommen‐

dations to be determined.

Further information A prepared list is provided in chapter10.19.

10.2.2 Resetting maintenance interval counters

According to the way a machine is equipped, sensors and/or maintenance interval counters monitor

the operational state of major components. Necessary maintenance tasks are indicated by the

SIGMA CONTROL.

Maintenance interval counters count down the operating hours to the next maintenance task.

Reset the counter to the original value once the task has been carried out.

Precondition Maintenance carried out?

Service message acknowledged.

Password level 4 activated.

1. Select the appropriate entry from the maintenance menu.

2. Select 'reset' and 'y' and confirm with the «enter» key.

Further information Detailed information can be found in the SIGMA CONTROL operating instructions.

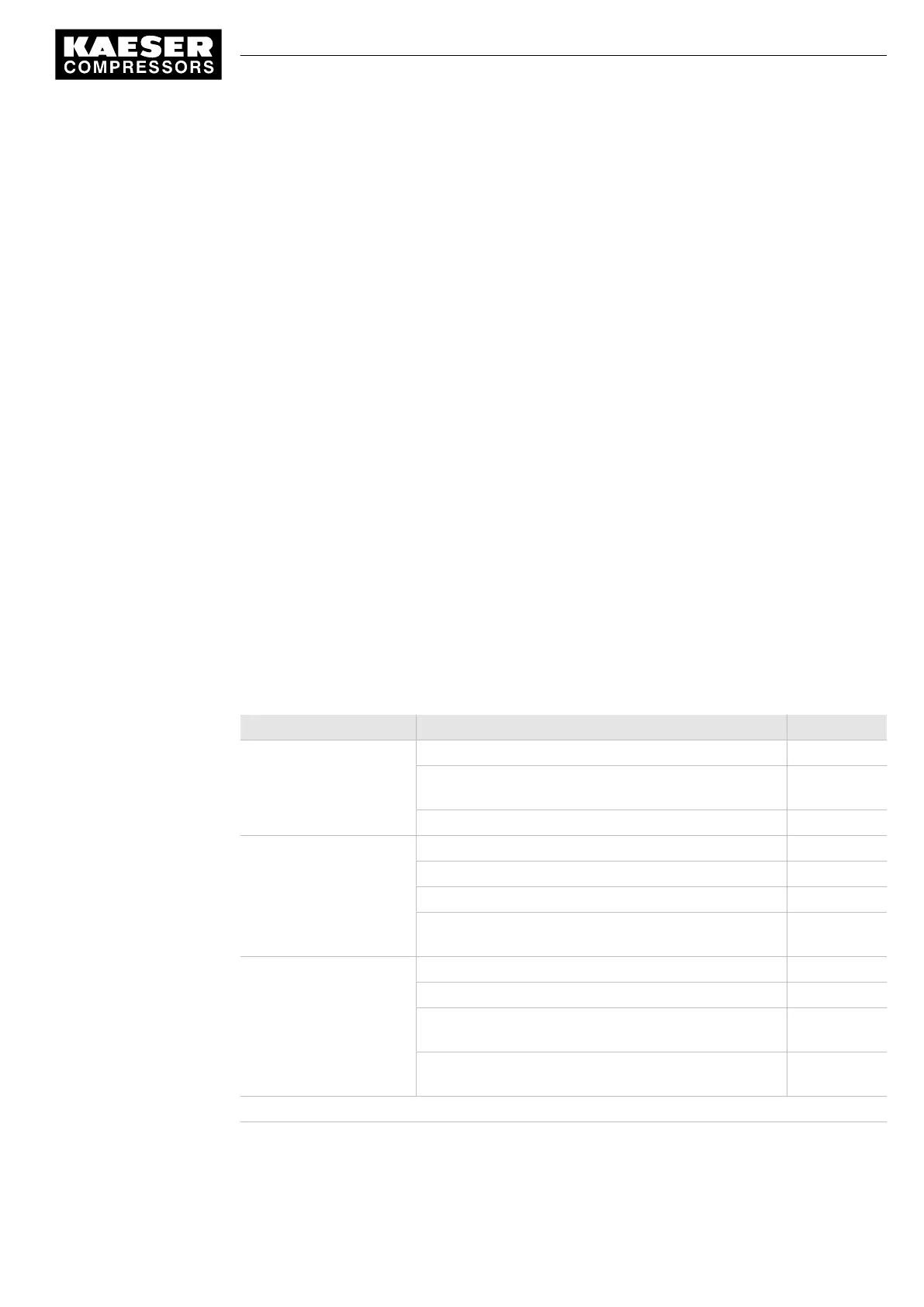

10.2.3 Regular maintenance tasks

The table below lists maintenance tasks required.

➤ Take note of the controller's service messages and carry out tasks punctually taking ambient and

operating conditions into account.

Interval Maintenance task See chapter

Weekly Check the cooling oil level 10.12

Control cabinet:

check the filter mat

10.4

Check the condensate drain 10.18.2

Up to 1,000 h Check the air filter 10.7

Clean the cooler 10.5

Clean the refrigerant condenser 10.18.1

Option K3:

clean the cooling air filter mat

10.3

SIGMA CONTROL dis‐

play

Up to 3,000 h

Check the coupling 10.9

Change the air filter element 10.7

Option K3:

change the cooling air filter mat

10.3

Control cabinet:

change the filter mat

10.4

h = operating hours

10 Maintenance

10.2 Maintenance Schedule

9_5721 06 USE

Service Manual Screw Compressor

ASD T Tri-Voltage

61

Loading...

Loading...