Material Brush and vacuum cleaner.

Breathing mask (if required).

Precondition The power supply disconnecting device is switched off.

The disconnecting device is locked in the off position.

A check has been made that no voltage is present.

The machine has cooled down.

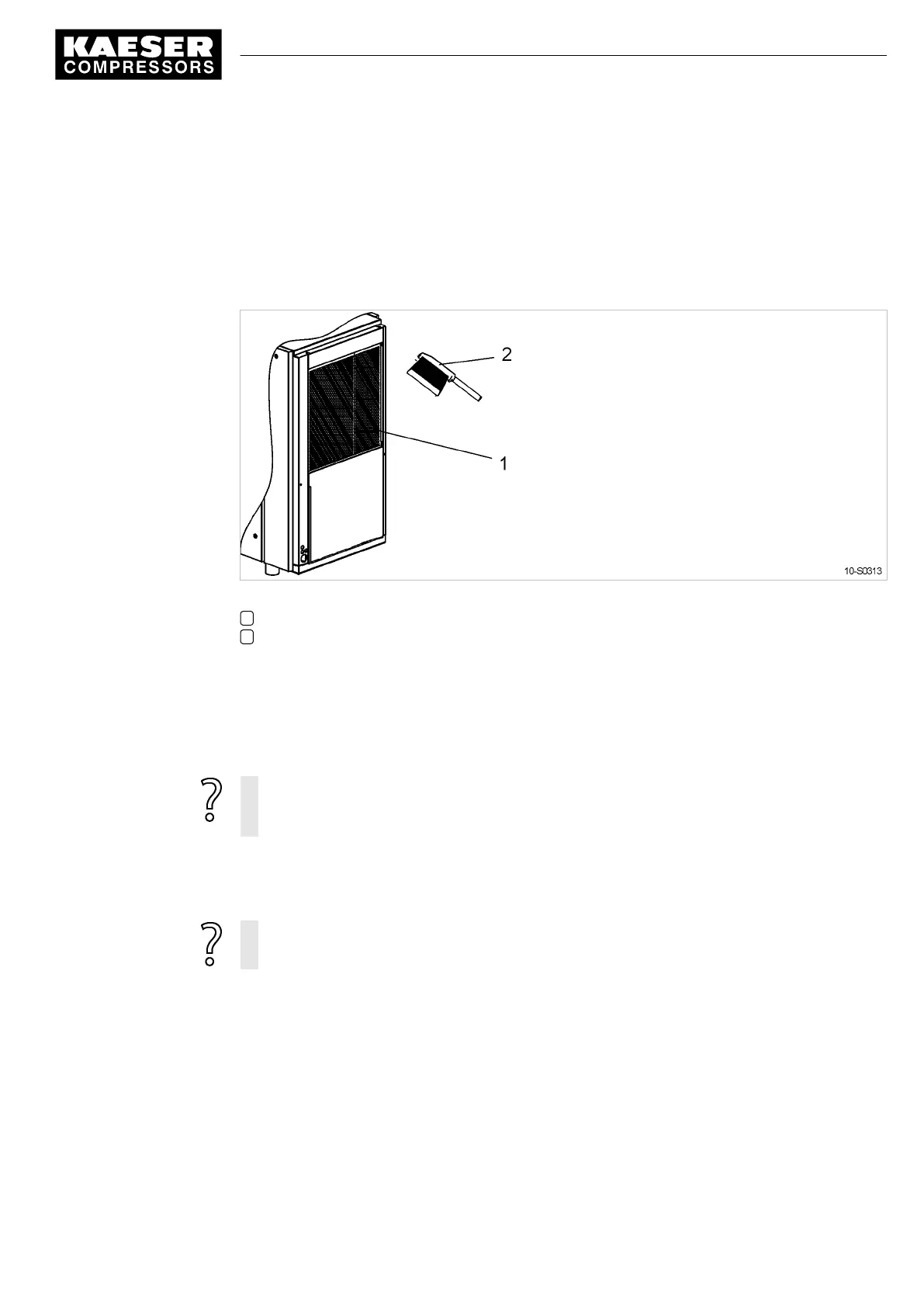

Fig. 26 Cleaning the cooler

1 Cooler

2 Brush

Cleaning the cooler

Do not use sharp objects to clean the cooler. It could be damaged.

Avoid creating clouds of dust.

➤ Dry brush the oil and air coolers and use a vacuum cleaner to suck up the dirt.

The air and oil coolers can no longer be properly cleaned?

➤ Heavy and stubborn contamination should be removed by a KAESER Service representa‐

tive.

Check the cooler for leaks

➤ Can cooling oil be seen to be leaking?

Is a cooler leaking?

➤ Have the defective cooler repaired immediately by KAESER Service representative.

10.6 Option W1/W2/W3

Heat Recovery System Maintenance

Deposits in the heat exchanger can significantly reduce its capacity to transfer heat.

Check the heat exchanger regularly for leaks and contamination. Frequency of checking is dependant

on the characteristics of the heat transfer medium.

➤ Monitor the pressure in the heat transfer medium to detect any pressure drop.

10 Maintenance

10.6 Heat Recovery System Maintenance

9_5721 06 USE

Service Manual Screw Compressor

ASD T Tri-Voltage

65

Loading...

Loading...