Section 6

Recirculation System

20412963

8-2012/Rev 07

6-3

NOTE

To conserve water usage it is recommended that the cooling water be shut off at

the end of the day. A sensor bulb from the modulating valve is submerged in the

reservoir. Even when the control power is off, the valve will remain open,

allowing water to flow until the oil is cooled.

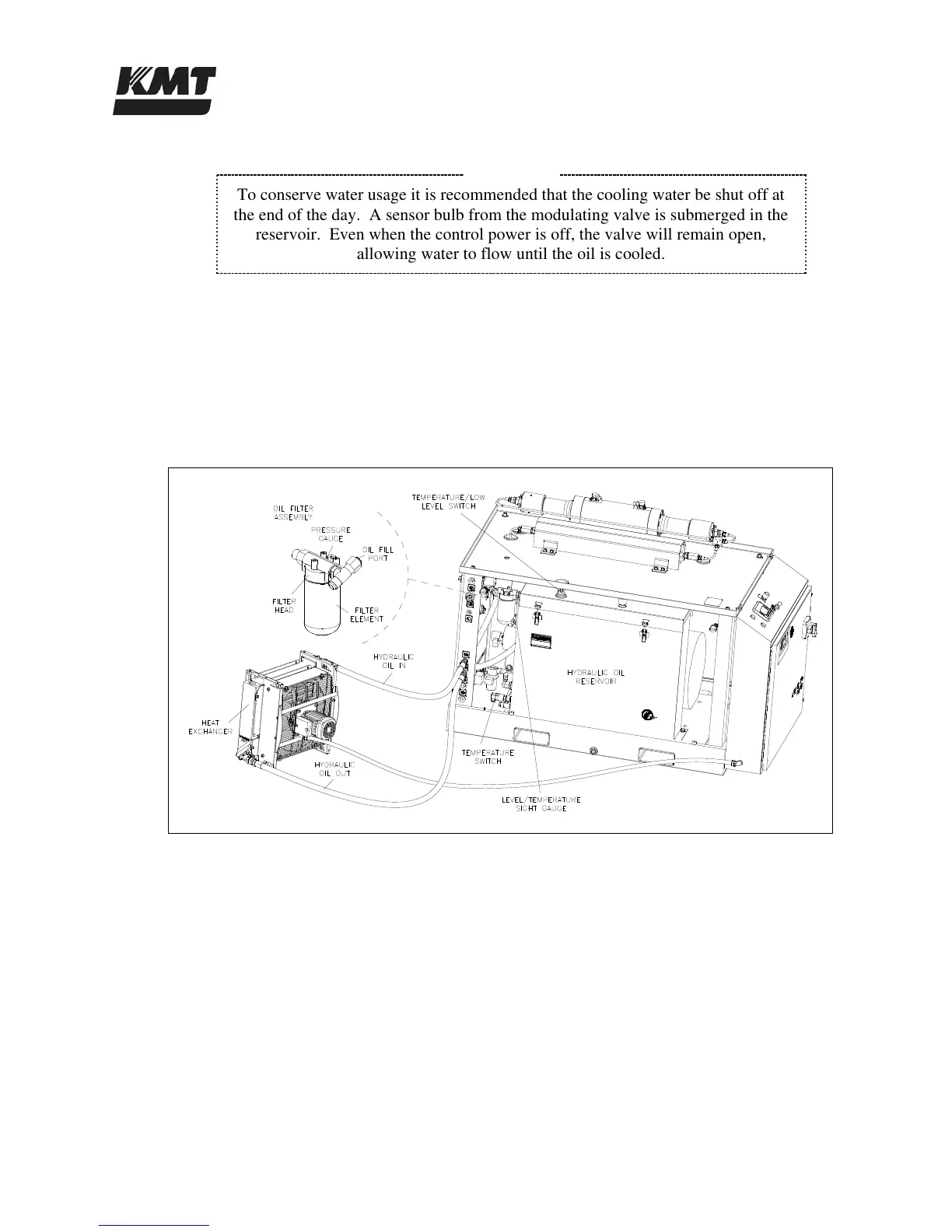

6.3 Operation (Oil-to-Air Models)

The recirculation pump pulls oil from the hydraulic oil reservoir and sends it to the external heat

exchanger. The oil-to-air heat exchanger controls heat build-up in the hydraulic oil. Oil

temperature can be visually monitored from a dual scale level/temperature sight gauge on the side

of the reservoir.

Figure 6-3: Recirculation System Components (Oil-to-Air)

The temperature switch mounted on the reservoir monitors the oil temperature and regulates the

air flow to the heat exchanger through a signal to the control panel to initiate power to the fan.

The cooled oil returns through the bulkhead, passes through the filter element and returns to the

reservoir.

The hydraulic oil filter assembly consists of the filter head, a filter element, pressure gauge or

indicator, bypass relief valve and the oil fill port. All 30, 50 and 60 horsepower machines are

equipped with a numeric pressure gauge that indicates inlet pressure. The filter element should

be changed when the gauge reads 40 psi (2.8 bar) at normal operating temperature. The 100

horsepower machines utilize a differential pressure indicator. The filter element on these

machines should be changed when the indicator enters the red zone at normal operating

temperature.

Loading...

Loading...