Section 9

High Pressure Water System

20412997

8-2012/Rev 12

9-16

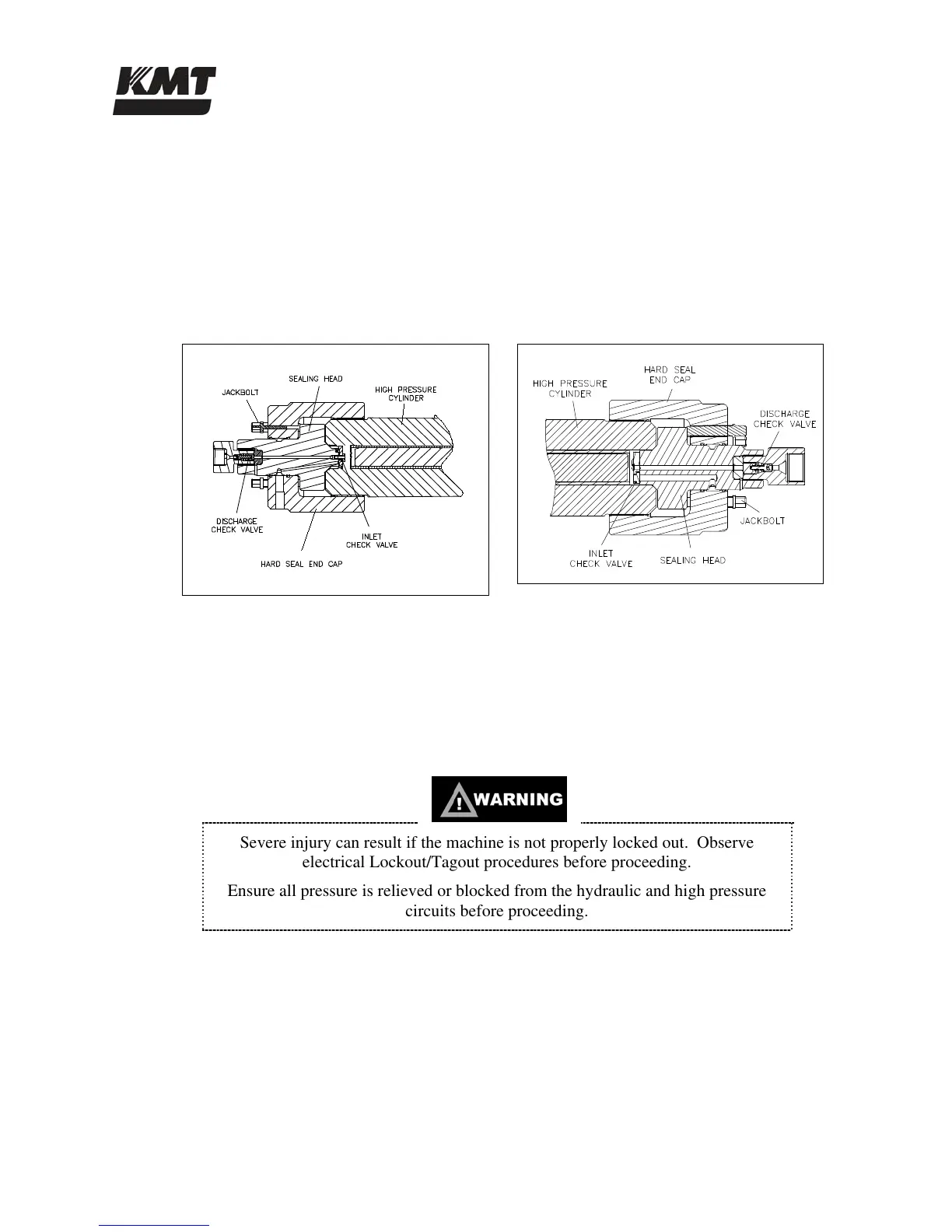

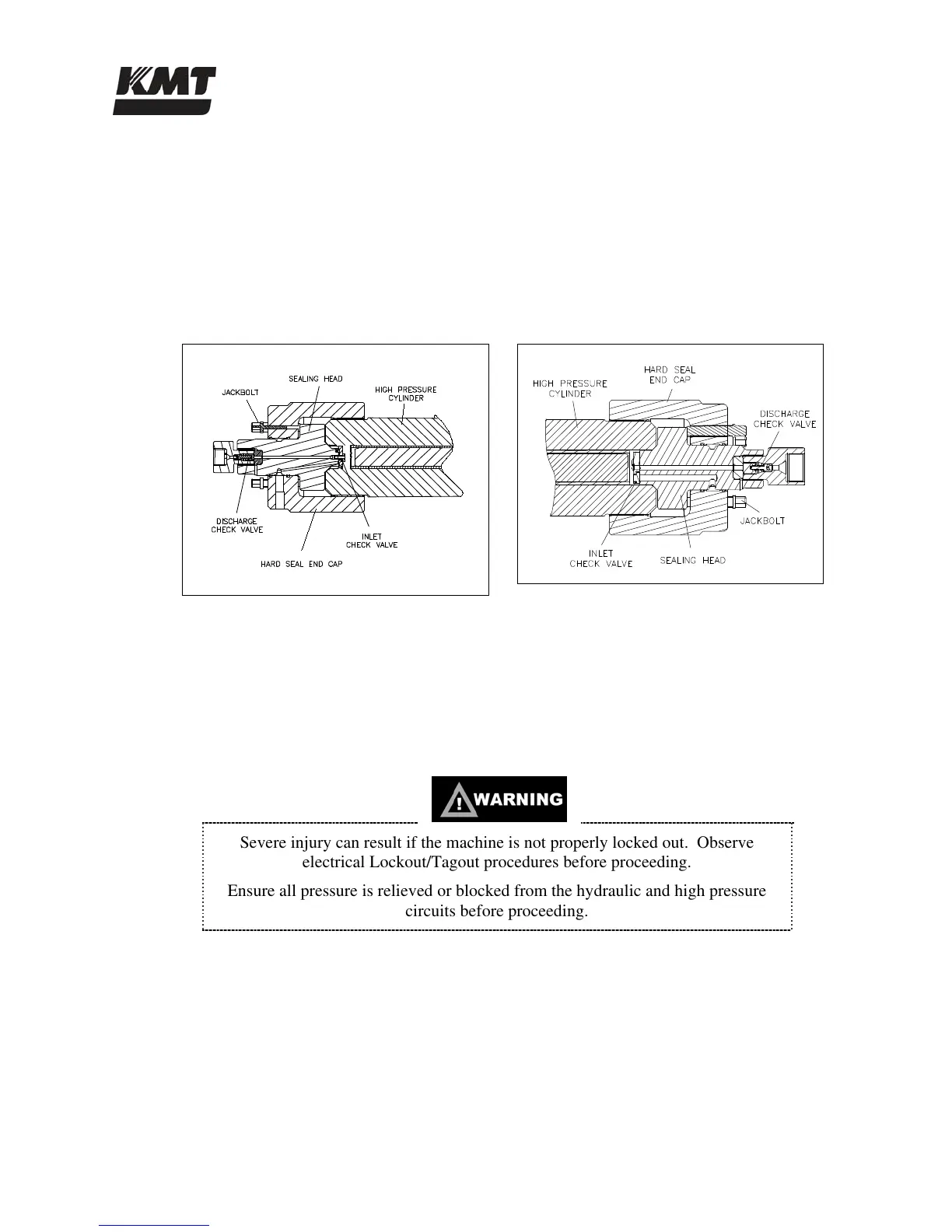

9.9 Sealing Head

The sealing head is sealed to the outboard end of the high pressure cylinder by a metal-to-metal

compression seal. The pre-loading jackbolts in the hard seal end cap hold the sealing head

against the end of the cylinder.

The inlet and discharge check valves in the sealing head ensure the low pressure and high

pressure water only travels in the appropriate direction.

Figure 9-10: Sealing Head

7/8” Plunger 1-1/8” Plunger

High Pressure Discharge Check Valve

The high pressure discharge check valves should be serviced on a regular, preventive

maintenance schedule. Service is recommended every 1,500 hours. The discharge check valve

can be serviced with the sealing head either installed or removed from the high pressure cylinder.

1. Turn the machine off and observe the appropriate Lockout/Tagout procedures.

Severe injury can result if the machine is not properly locked out. Observe

electrical Lockout/Tagout procedures before proceeding.

Ensure all pressure is relieved or blocked from the hydraulic and high pressure

circuits before proceeding.

2. Disconnect the high pressure water piping, following the procedure, High and Low

Pressure Water Piping.

3. Use two wrenches to remove the discharge gland nut. The poppet pin, spring and

discharge poppet will normally remain in the gland nut when it is removed. Remove the

components from the gland nut.

4. Use a magnet to remove the seat from the sealing head.

Loading...

Loading...