Section 9

High Pressure Water System

20412997

8-2012/Rev 12

9-20

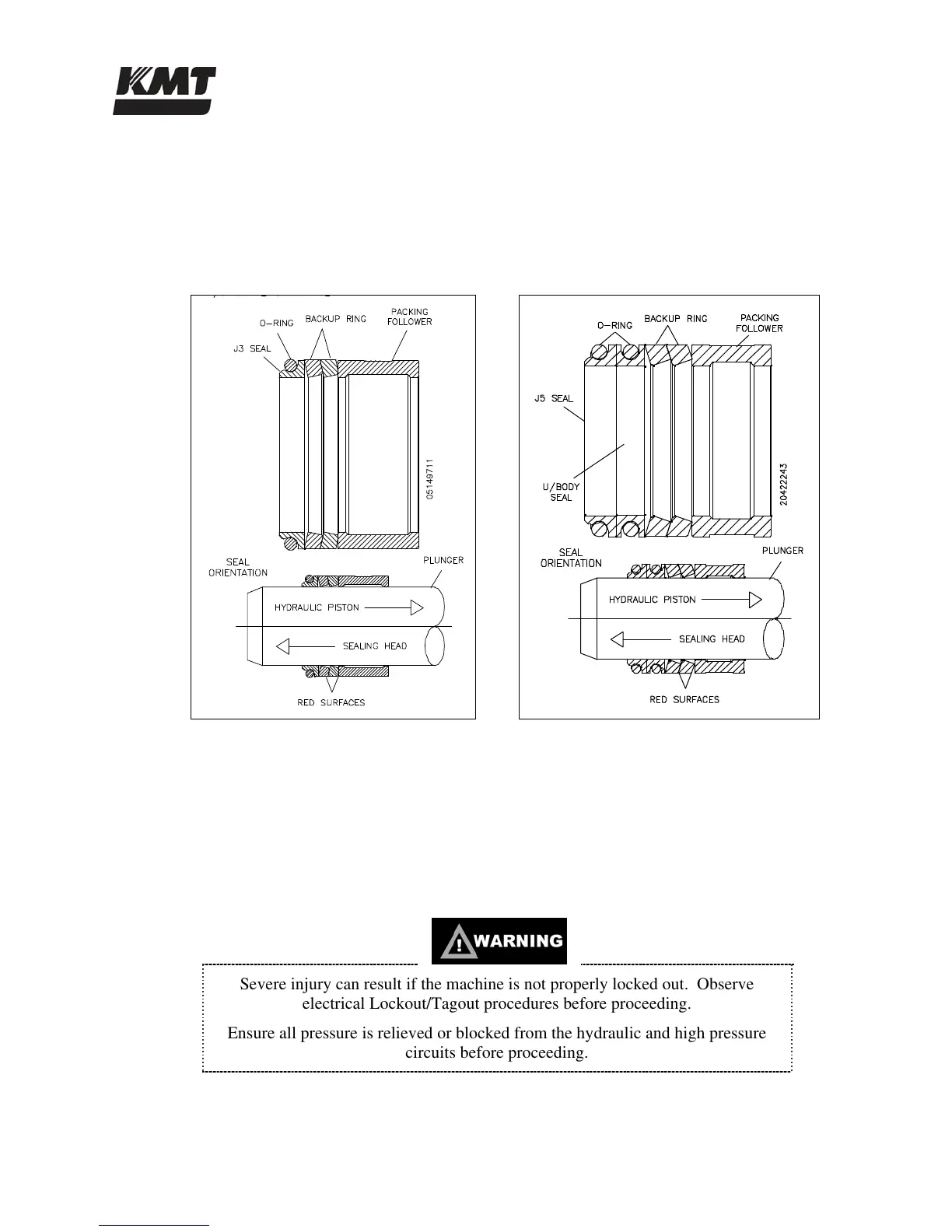

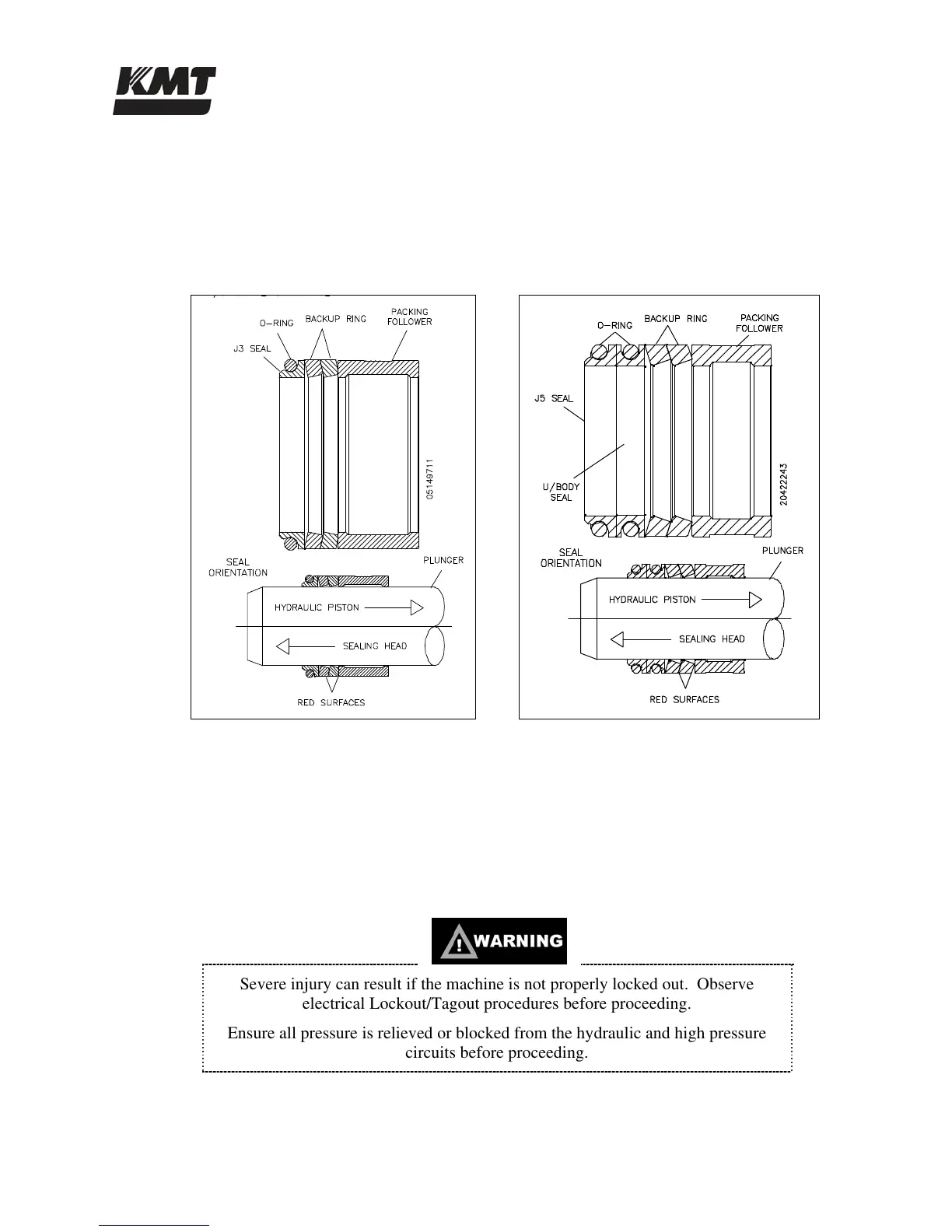

9.10 High Pressure Seal Assembly

The following procedure should be used to replace the high pressure seal assembly. Seal

components differ slightly, depending on the plunger diameter. See Figure 9-13, High Pressure

Seal Assembly.

Figure 9-13: High Pressure Seal Assembly

7/8” Plunger 1-1/8” Plunger

Prior to removing electrical power or any high or low pressure piping, start the machine from the

Maintenance Screen on the control panel. The machine will start in recirculation mode; the dump valve

will open and relieve the high pressure in the system.

Press the

RIGHT or LEFT arrow to extend the plunger on the end to be serviced. The plunger will extend in

the selected direction, allowing full exposure when the unit is disassembled.

1. Turn the machine off and observe the appropriate Lockout/Tagout procedures.

Severe injury can result if the machine is not properly locked out. Observe

electrical Lockout/Tagout procedures before proceeding.

Ensure all pressure is relieved or blocked from the hydraulic and high pressure

circuits before proceeding.

Loading...

Loading...