Section 9

High Pressure Water System

20412997

8-2012/Rev 12

9-12

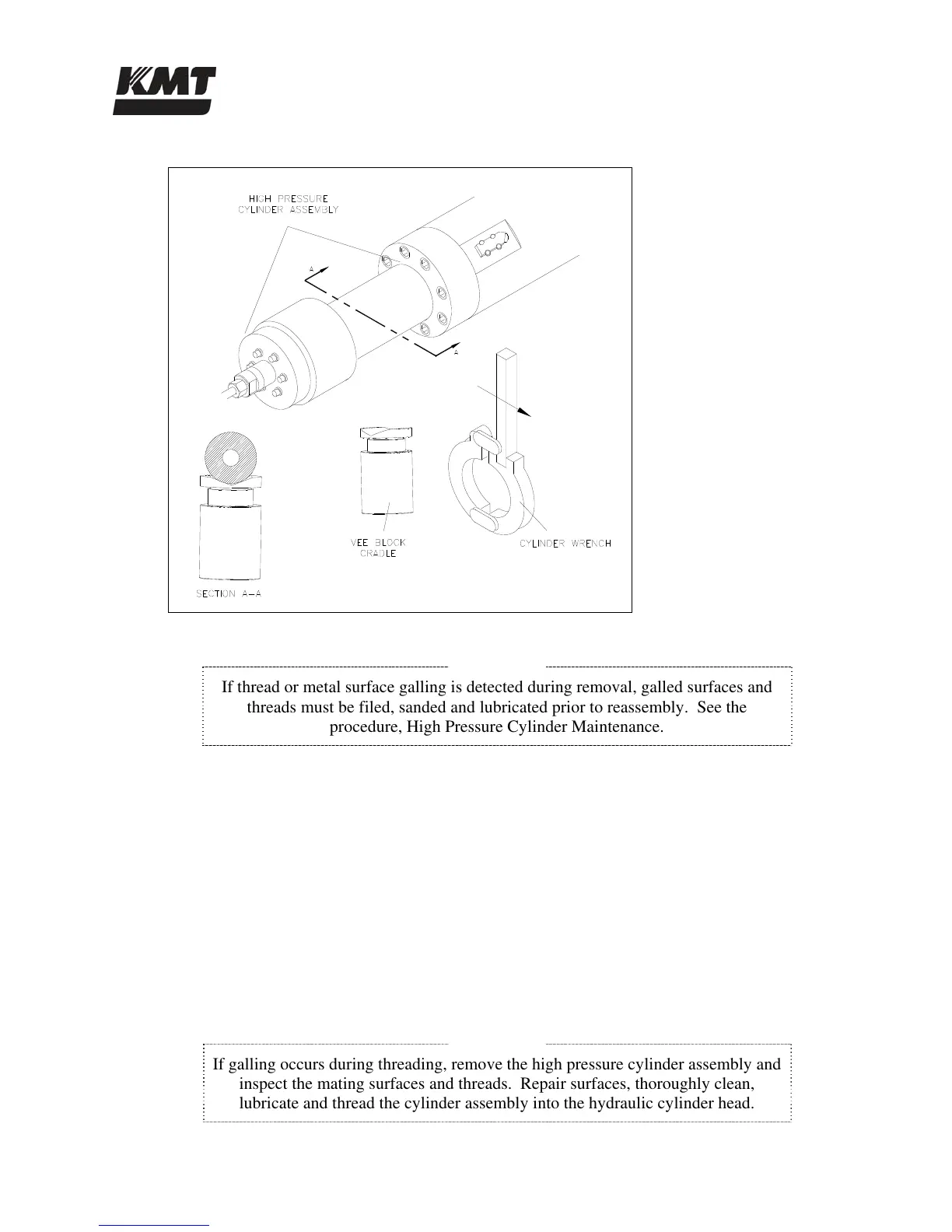

Figure 9-8: High Pressure Cylinder Assembly Removal and Installation

NOTE

If thread or metal surface galling is detected during removal, galled surfaces and

threads must be filed, sanded and lubricated prior to reassembly. See the

procedure, High Pressure Cylinder Maintenance.

High Pressure Cylinder Assembly Installation

1. Verify that the high pressure cylinder threads and alignment surfaces are adequately

cleaned and lubricated with Pure Goop, and that the threads have been sanded and dressed

if galling was encountered during removal.

2. Verify that the high pressure seal assembly, packing follower and cylinder liner are

correctly installed. Align the cylinder assembly with the plunger and the hydraulic

cylinder head, using the cradle tool to support the weight. Carefully push and lift the

assembly into position until the threads are ready to engage.

3. Thread the cylinder assembly into the hydraulic cylinder head.

NOTE

If galling occurs during threading, remove the high pressure cylinder assembly and

inspect the mating surfaces and threads. Repair surfaces, thoroughly clean,

lubricate and thread the cylinder assembly into the hydraulic cylinder head.

Loading...

Loading...