Section 9

High Pressure Water System

20412997

8-2012/Rev 12

9-27

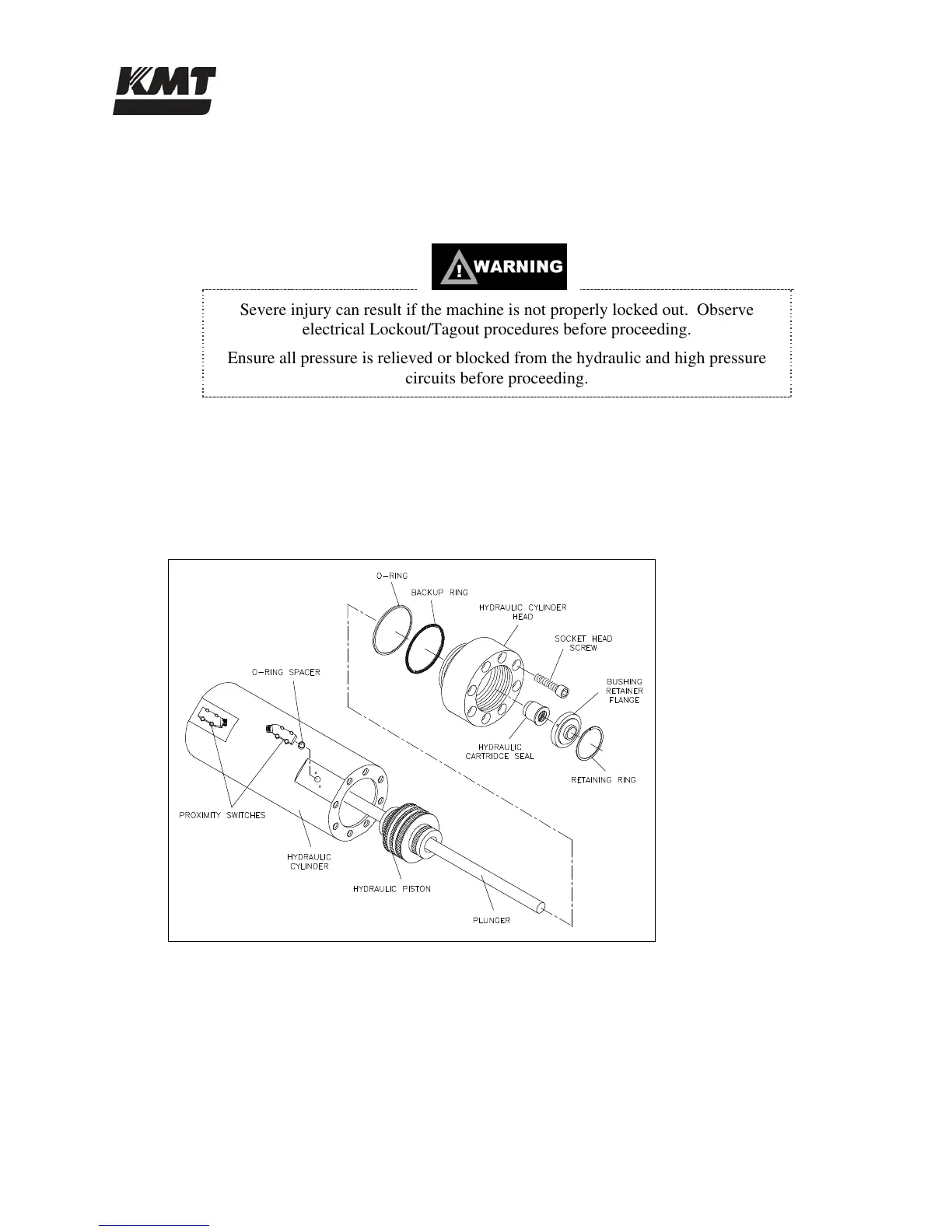

Hydraulic Piston Removal

The following procedure is used to remove the hydraulic piston.

1. Turn the machine off and observe the appropriate Lockout/Tagout procedures.

Severe injury can result if the machine is not properly locked out. Observe

electrical Lockout/Tagout procedures before proceeding.

Ensure all pressure is relieved or blocked from the hydraulic and high pressure

circuits before proceeding.

2. Disconnect the high and low pressure water piping from both ends of the intensifier,

following the procedure, High and Low Pressure Water Piping.

3. Remove the high pressure cylinder assembly on each end of the intensifier, following the

procedure, High Pressure Cylinder Assembly Removal.

Figure 9-20: Hydraulic Piston Removal

4. Remove both of the proximity switches to prevent interference and to allow the hydraulic

oil to drain back to the reservoir, minimizing oil spillage. It will take approximately five

minutes for the oil to drain.

5. Remove the retaining ring, bushing retainer flange and the hydraulic cartridge seal from

both hydraulic cylinder heads. It is not necessary to remove the plunger.

6. Loosen and remove the socket head screws in one of the hydraulic cylinder heads.

Loading...

Loading...