Section 2

Installation

20412922

8-2012/Rev 10

2-5

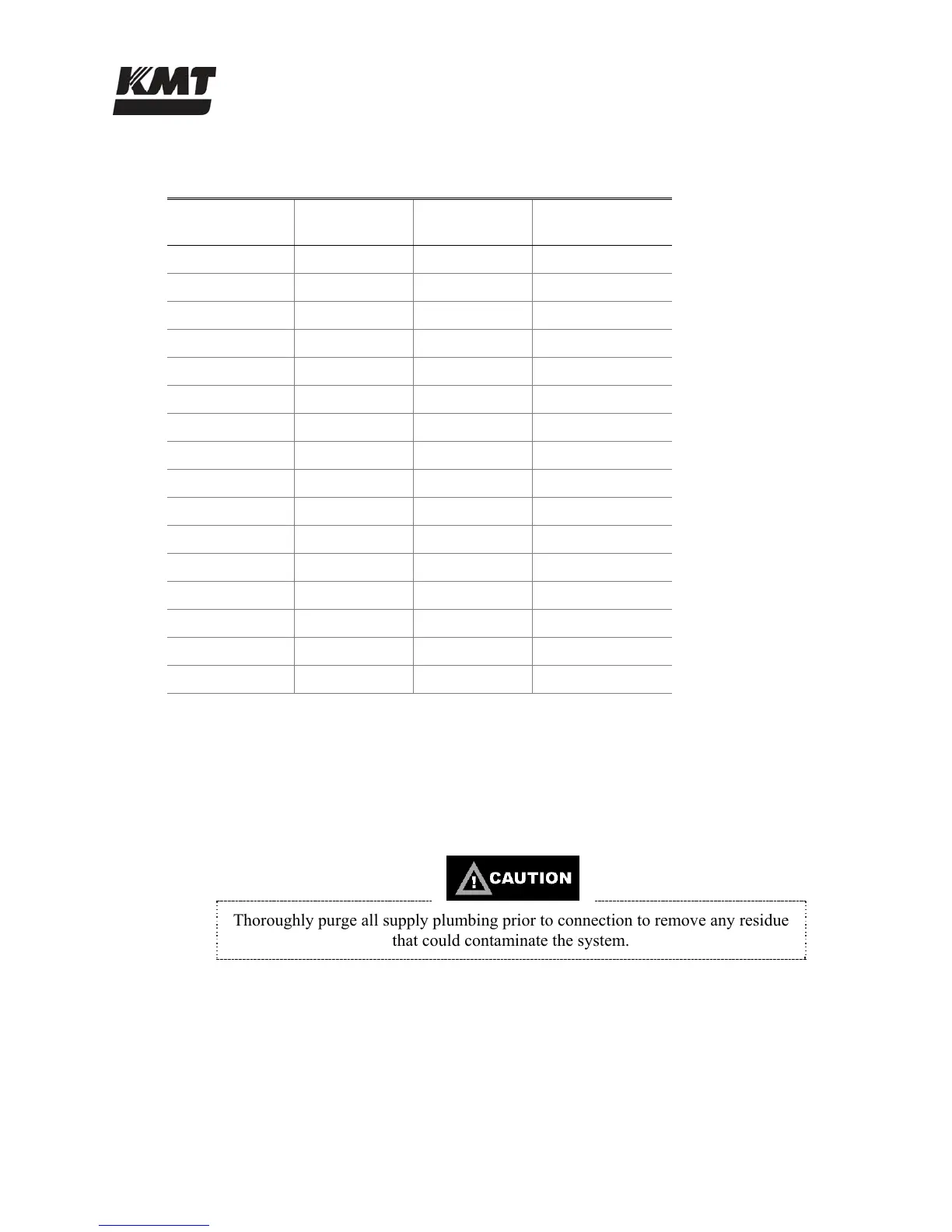

Table 2-3

Ampacity and Power Voltage Requirements

Power Voltage

Motor

Horsepower

Full Load

Amps

Circuit Breaker

Amps

230/3/60 50 116 150

380/3/50 50 69 100

400/3/50 50 66 100

415/3/50 50 64 100

460/3/60 50 58 80

575/3/60 50 52 70

230/3/60 60 140 175

380/3/60 60 86 125

460/3/60 60 70 90

200/3/50-60 100 248 350

200-208/3/50-60 100 248/242 350

230/3/60 100 218 300

400/3/50 100 124 175

415/3/50 100 121 175

460/3/60 100 109 175

575/3/60 100 99 125

2.5 Service Connections

The intensifier requires two incoming water sources, cooling water and cutting water; two drain

lines, cooling water and wastewater; a high pressure discharge line, and an air supply line. All

piping must comply with local, regional and national codes.

Thoroughly purge all supply plumbing prior to connection to remove any residue

that could contaminate the system.

All service connections are made on the rear bulkhead of the machine as shown in Figure 2-3,

Service Connections. Table 2-4 lists the fittings required and the height of each interface

connection.

With the exception of the wastewater and contaminated waste drain lines, manual shutoff valves

should be installed for all connections. To facilitate service, the valves should be located as close

as practical to the interface connection.

Loading...

Loading...