Mounting

Leuze electronic GmbH + Co. KG BPS 307i 35

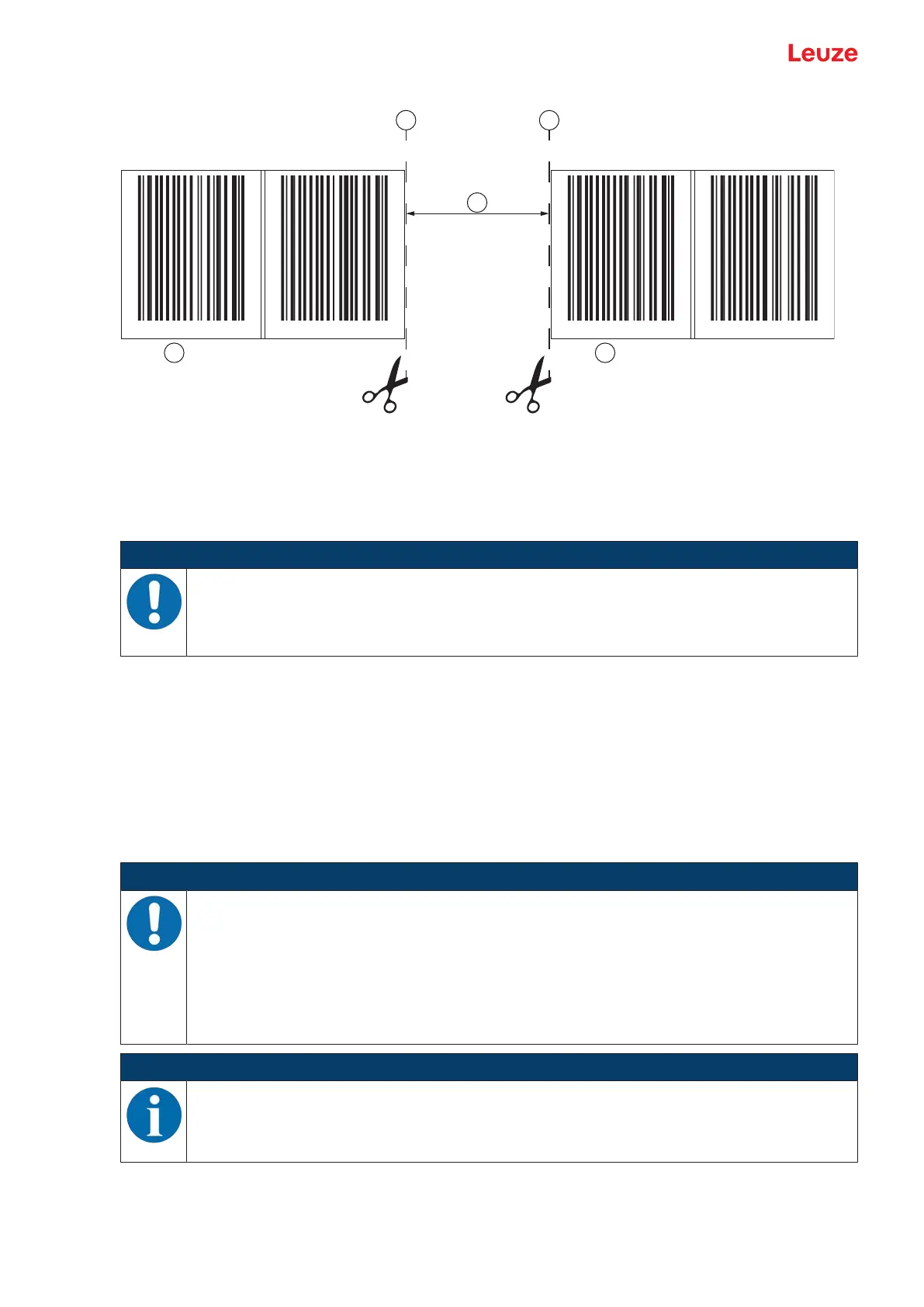

000040 000044 000064 000068

2

2

1

3

4

G40Leuze G40Leuze G40Leuze G40Leuze

1 Preceding barcode tape

2 Cut mark

3 Gap, at least 300mm

4 Subsequent bar code tape

Fig.6.3: Gap in cut barcode tape to avoid double positions

NOTICE

No glossy gaps in the cut barcode tape!

Ä Ensure that there are matt, bright surfaces behind the gaps in the BCB.

Polished, reflective, and high-gloss surfaces in the scanning beam may impair the measure-

ment quality of the BPS.

6.1.3

Mounting the BCB

Mount the BCB as follows:

Ä Check the surface.

It must be flat, free of grease and dust, and be dry.

Ä Define a reference edge (e.g., metal edge of the busbar).

Ä Remove the backing and affix the BCB along the reference edge tension free.

Ä Secure the bar code tape to the mounting surface by pressing down with the palm of your hand. When

affixing, make certain that the BCB is free of folds and creases and that no air pockets form.

NOTICE

When mounting, do not pull on the BCB!

The BCB is a plastic tape that can be stretched by strong mechanical tension.

The stretching results in lengthening of the tape and distortion of the position values on the

BCB.

While the BPScan still perform the position calculation in the event of distortions, the absolute

measurement accuracy is no longer ensured in this case. If the values are taught using a teach-

in process, stretching of the BCB is irrelevant.

NOTICE

If a barcode tape was damaged, e.g., by falling parts, you can download a repair kit for the BCB

from the Internet (see chapter 11.2.2 "BCB repair with repair kit").

Ä Use the barcode tape created with the repair kit only temporarily as an emergency solution.

Loading...

Loading...