Technical data

Leuze electronic GmbH + Co. KG BPS 307i 80

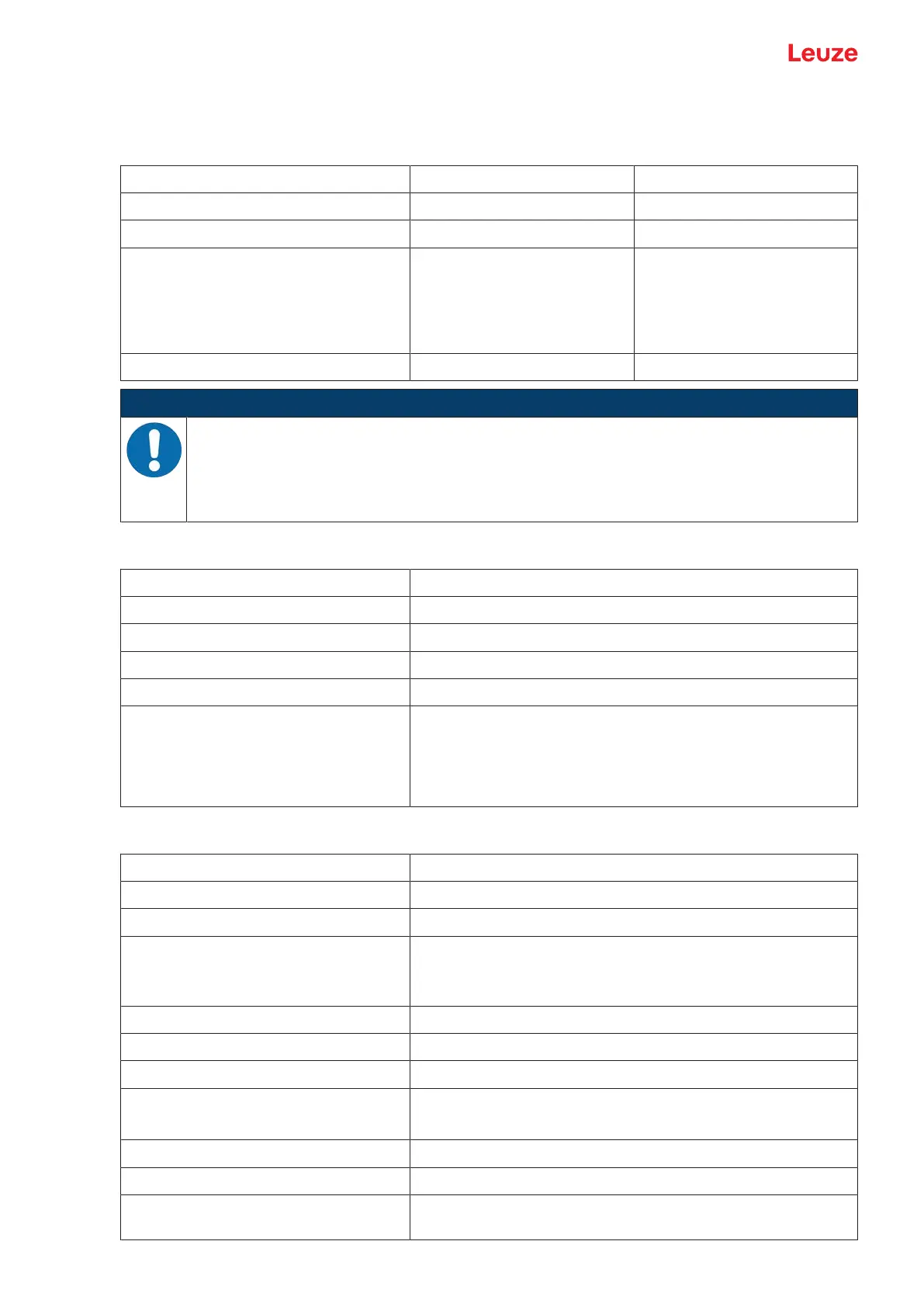

13.2 Bar code tape

Tab.13.11: BCB dimensions

BCBG40… BCBG30…

Grid 40mm 30mm

Standard height 47mm, 25mm 47mm, 25mm

Length 0…5 m, 0…10 m, 0…20 m,

…, 0…150 m, 0…200 m;

Special lengths and special

encodings: see chapter 14

"Order guide and accessories"

0…5m, 0…10m,

0…20m, …, 0…150m;

Special lengths and special

encodings: see chapter 14

"Order guide and accessories"

Tape tolerance ±1mm per meter ±1mm per meter

NOTICE

Twin tapes on request

Ä An entry wizard for twin tapes with custom tape start value, tape end value, custom length

and height is available on the Leuze website under devices BPS300 – Accessories. The en-

try wizard provides support when entering the individual pieces of tape data and creates a

query or order form for the desired twin tape.

Tab.13.12: BCB structure

Manufacturing process Filmsetting

Surface protection Polyester, matt

Base material Polyester film, affixed without silicone

Adhesive Acrylate adhesive

Strength of adhesive 0.1mm

Adhesive strength (average values) On aluminum: 25N/25mm

On steel: 25N/25mm

On polycarbonate: 22N/25mm

On polypropylene: 20N/25mm

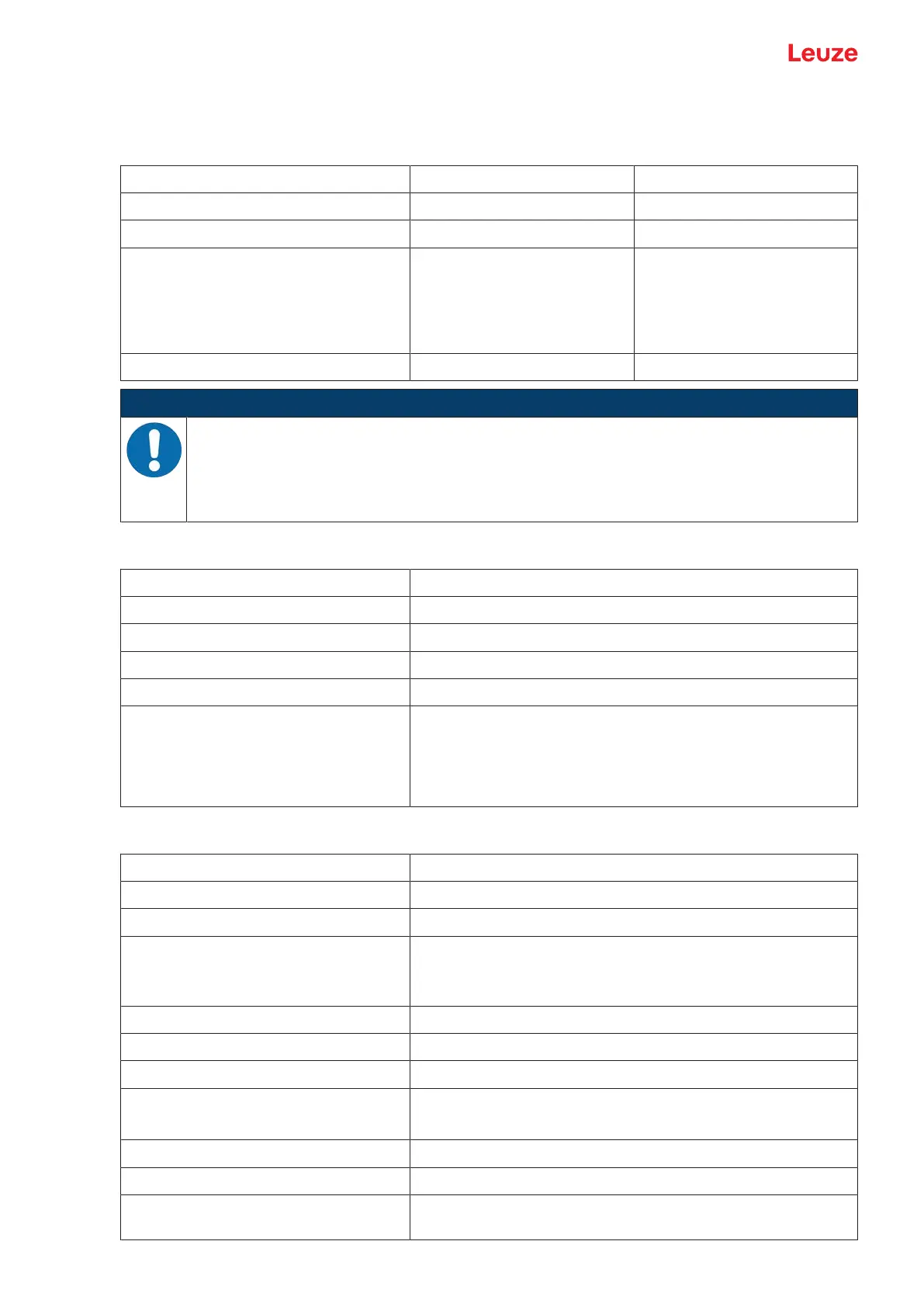

Tab.13.13: BCB environmental data

Recommended processing temperature 0°C…+45°C

Ambient temperature -40°C…+120°C

Dimensional stability No shrinkage, tested according to DIN30646

Curing Final curing after 72h;

the BPS can detect the position immediately after the BCB is

affixed.

Tear resistance 150N

Elongation at tear Min.80%, tested in accordance with DIN50014, DIN51220

Weathering resistance UV-light, humidity, salt spray (150h/5%)

Chemical resistance

(checked at 23°C over 24h)

Transformer oil, diesel oil, white spirit, heptane, ethylene glycol

(1:1)

Behavior in fire Self-extinguishing after 15s, does not drip

Surface Grease-free, dry, clean, smooth

Mechanical properties Scratch and wipe resistant, UV resistant, moisture resistant,

partly chemical resistant

Loading...

Loading...