17B-35

PETROL INJECTION

Oxygen sensor fault finding

L90, and K7J, and 710 – L90, and K7M, and 710

17B

FOR VEHICLES FITTED WITH O.B.D:

The purpose of oxygen sensor fault finding is to detect

a fault which would cause the On Board Diagnostic limit

to be exceeded by hydrocarbon pollutant emissions. It

is performed by measuring and comparing oxygen sen-

sor vibration periods.

There are two types of possible faults on the oxygen

sensors:

- mechanical damage to an electrical component (brea-

kage, cut in wire) which leads to an electrical fault,

- chemical damage to the component which causes the

response time of the sensor to slow down, thus in-

creasing its switching period.

When the required test conditions are met, the average

of the sensor periods read is taken, subtracting the ef-

fects of interference, then compared with a period of

the On Board Diagnostic limit.

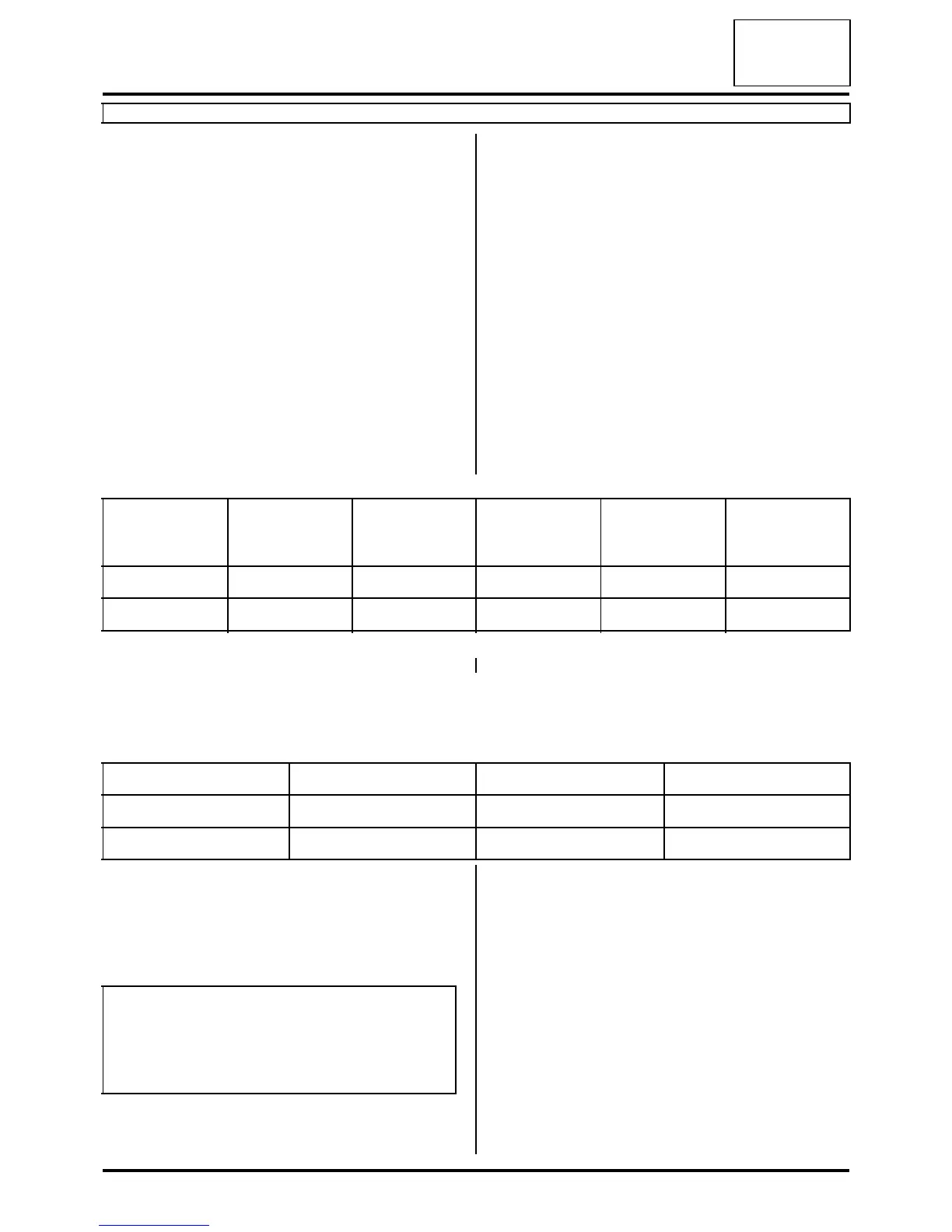

I -TEST CONDITIONS

Fault finding of the oxygen sensor can only take place

after the engine has been running for a while and under

specific operating conditions, detailed in the table be-

low, and if all the conditions prior to the ignition being

switched on are met and maintained:

- no electrical faults detected,

- programming and cylinder recognition done,

- no oxygen sensor fault finding performed since the

ignition was switched on,

- water temperatureover 75˚C.

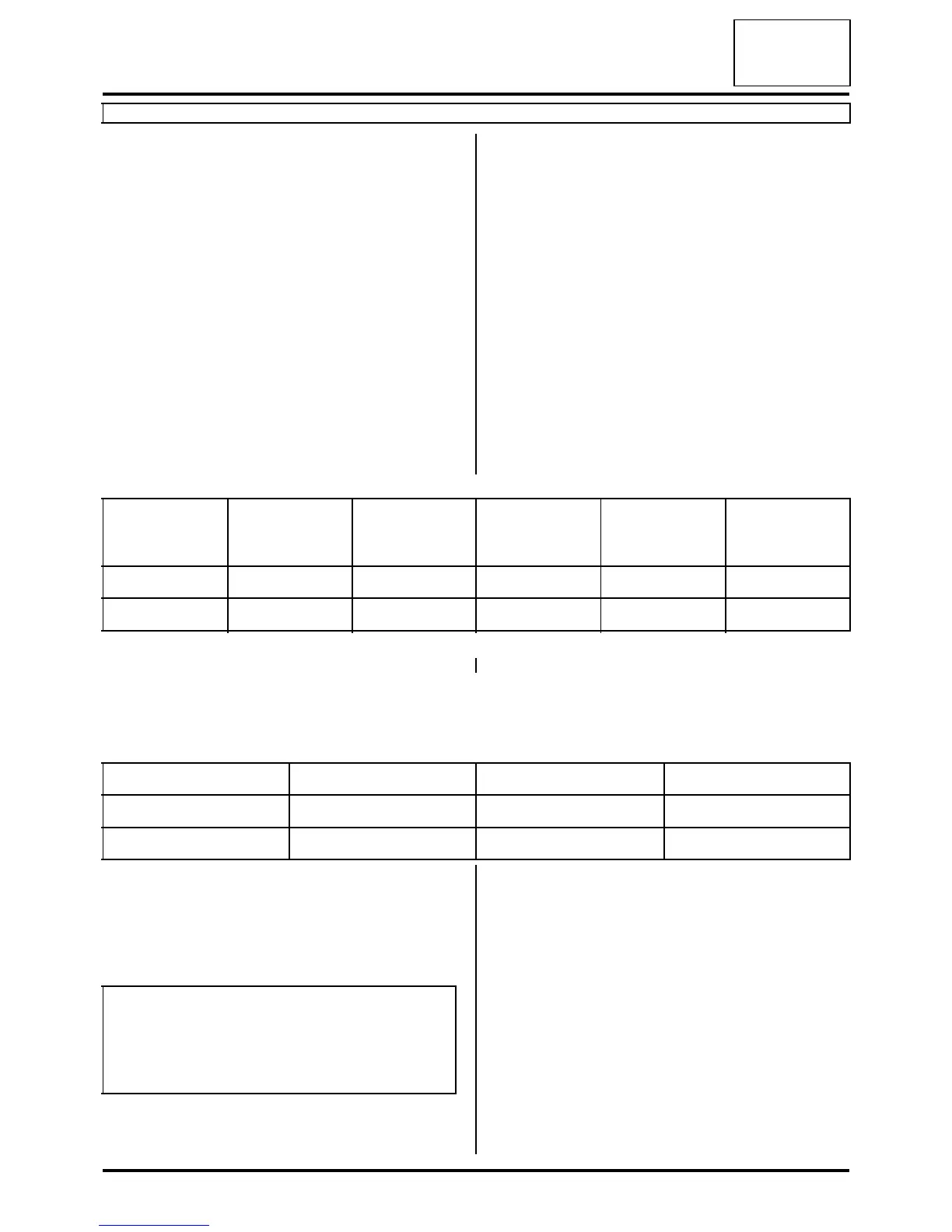

II - FAULT DETECTION

Fault finding is performed while the vehicle is being driven in one gear, travelling at a steady speed and for

the minimum period of time specified in the following table:

For this test, the computer inhibits petrol vapour canis-

ter bleeding.

The computer gives the « sensors fault finding

included » signal.

If after the test, the diagnostic tool has found a lambda

sensor fault, (see Workshop Repair Manual 390 Fault

finding, 17B, Petrol injection, Summary of faults).

III - CONFIRMATION OF REPAIR

- ET102: « Sensor fault finding included »:

« ACTIVE »,

- ET106: « Sensor fault finding done »: « ACTIVE »,

- no fault detected and the On Board Diagnostic war-

ning light is out.

Engine Speed, mph

(kph)

Engine speed

(rpm)

Manifold pres-

sure (mbar)

Stabilisation

time (seconds)

Time before

autorisation

(minutes)

K7M 63 to 130 1,856 to 3,808 380 to 850 8 14

K7J 63 to 130 1,856 to 3,808 380 to 850 8 14

Engine Gearbox ratio Speed, mph (kph) Maximum period (s)

K7J 5 70 40

K7M 5 70 40

WARNING

At the end of each test, it is essential that the igni-

tion is not switched off before the result is read on

the diagnostic tool. Switching off the ignition will

lead to the results being misinterpreted.

Loading...

Loading...