8

167

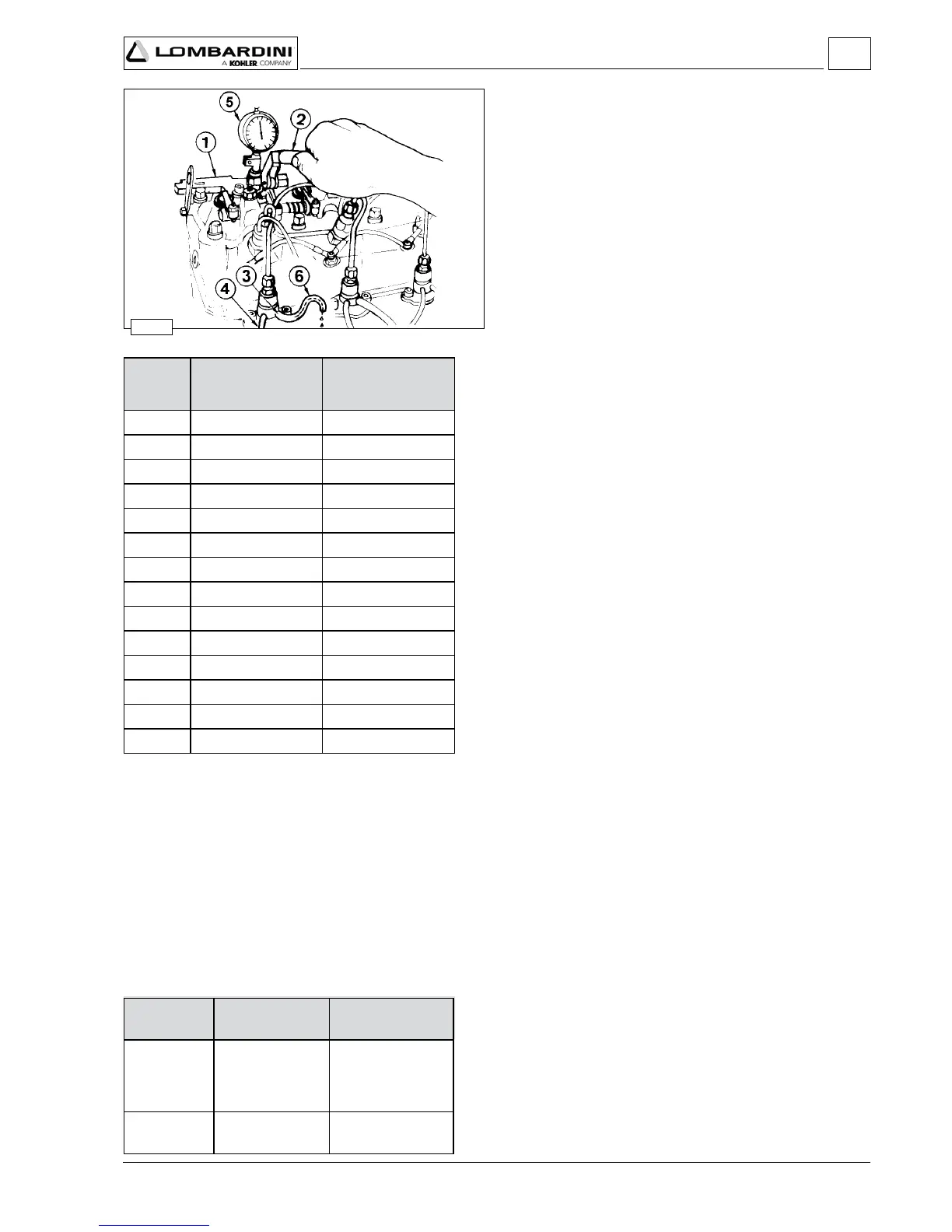

Injection timing

value for

r.p.m. ≥ 2400

Engine

type

Injection timing value

for r.p.m. ≤ 2400

Checking low pressure injection timing for engines with

mechanical tappets

The check of the advance on engines with mechanical tappets

is carried out using the same procedure as that described for the

hydraulic tappets; the only difference is in the disassembly and

reassembly of the rocker-arm pin and of the push rods which is

not necessary.

Fuel system

Rotate the crankshaft so as to position the pistons at half stroke for three-cylinder engines.

For four-cylinder engines, place the piston of cylinder number one at 150° after the top dead centre (in crossover stage).

The rocker-arm pin must be fastened in different stages so as to allow the oil inside the tappets to be drained, thus allowing them

to position themselves correctly.

Oil density and ambient temperature are important factors that will affect the waiting time (about 10') between successive fastening

operations.

Hurried fastening can cause serious damage to the engine.

As a guideline to each fastening operation, make sure that the cup of the upper spring bearing ring does not touch the valve stem

oilsealingringttedontheguide.

Thenaltorqueoftherocker-armpinis50Nm.

Reassemble the rocker-arm cap and the intake manifold, tightening the screws to the indicated torque.

Checking low pressure injection timing for engines with

hydraulic tappets

Toverifythedeliverystartingpoint,therstoperationtocarryout

is to disconnect the nylon tubes at the inlet 4 and outlet 3 of every

injection pump.

Then,disassembletheairlter,theintakemanifoldandtherocker

arm cap.

Now disassemble the whole rocker-arm pin and, after removing

the push rods, reassemble it.

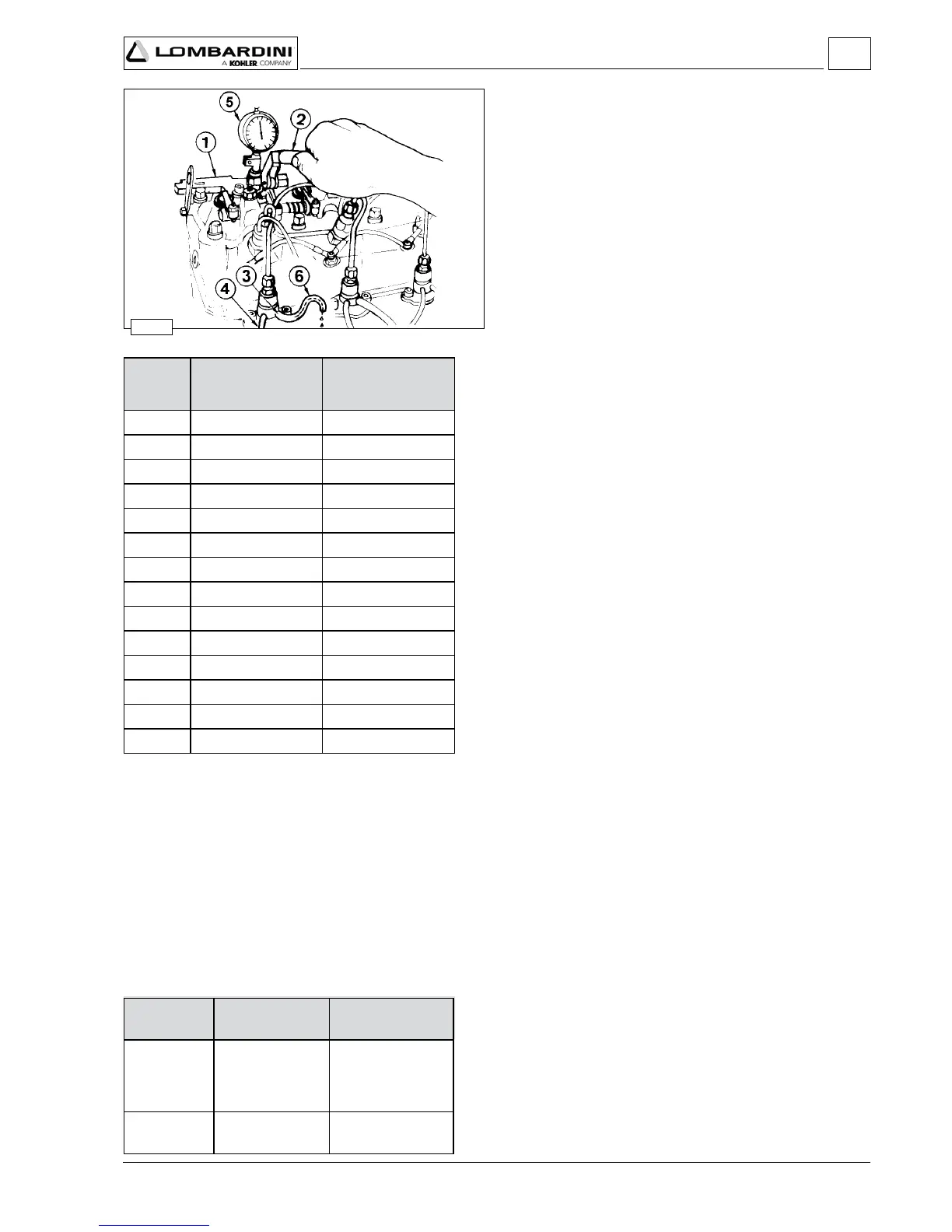

Screw the special tool 1serialnumber7107-1460-075(g.167)

onto the head, making sure the dial indicator tracer 5 sets against

the upper spring bearing ring of the intake valve.

Use a provisional fuel tank (e.g. delivery balancing tool) to gravity-

feed the injection pump connecting it to the inlet union 4; on the

outlet union 3tthetransparentnylontube6 by the means of which

wemeasuretheoverow.

Place the pump control rod in the stop position.

Operate the lever 2 of the tool to rotate the crankshaft until the

valve touches the piston crown.

This procedure determines the exact TDC (top dead centre of the

piston) of the cylinder in question; reset the dial indicator in this

position.

Then rotate clockwise the crankshaft on the ywheel side until

dieselfuelbeginstoowoutofthesmallhoseonthepumpoutlet.

Now change the rotation direction to anticlockwise.

Theowdiminishes.

Assoonasitstopsowing,thedeliverystartingpointisdetermined.

Then, lower the tool lever to make contact between the valve and

the piston crown and, using the dial indicator 5, measure how much

lower the piston is with respect to the TDC (top dead centre) in mm.

Use the transformation chart (mm to degrees) to nd out the

correspondence between mm measured with the dial indicator 5

and degrees.

Example LDW 1503-2004-2004/T: an advance of α=15°

corresponds to a lowering of the piston with respect to the TDC

(top dead centre) of 1.86 mm.

The same operation must be carried out on each pump.

The difference in adjustment must be limited to about 1°.

Disassemble the various equipment, remove the rocker-arm pin

and put back the push rods in their seats.

Then re-assemble the rocker-arm pin.

Loading...

Loading...