- 69 - Workshop Manual LDW CHD _ cod. 1.5302.345 - 6° ed_rev. 05

163

161

164

8

162

How to reassemble injection pump feeding tubes

1 Pliers for 6 mm diam. tubes (intake) - Part No. 7104-1460-

022

2 Pliers for 8 mm diam. tubes (discharge) - Part No. 7104-

1460-023

Feedinganddischargetubesaremadeofnylon;theytintothe

injection pump unions by exerting pressure and using special

pliers and a plastic hammer.

The nylon tubes can no longer be used after disassembly.

Replace them every time they are removed.

Instrument for equalizing injection pump delivery

Part No. 7104-1460-090

Components: 1 Tank 2 Test tube

3 Support 4 Switching lever

5 Injection pump discharge tube cut-off valve

6 Injection pump intake tube-off valve

A Tube for connection to injection pump intake union

B Tube for connection to injection pump discharge union

Removefeedtubesfromallinjectionpumpsandttheinstrument

tubes making sure that each pump has its own intake and

discharge tubes. Connect the instrument A with the engine A and

the instrument B with the engine B. Proceed in a similar manner

with the other pumps.

Injection pump delivery equalization.

After checking the injection advance go ahead with the delivery

balancing of the pumps.

Before connecting the tool serial number 7104-1460-090 to the

pumpsandrellingtank1 with fuel, set it to a higher level of at

least 200 mm than that of the pumps themselves.

Open taps 5 and 6 and start the engine, set the engine to an idling

speed of 2000 rpm. Switch the engine feed from tank 1 to the tubes

2 using the switching lever 4g.163.

Aftertherstminute(minimumtestingtime),verifythatthelevel

between the highest and lowest levels in the tubes is not more

than 2 cm³.

At this point, it is possible to either reduce the delivery of the

pump that consumes most (tube with the lowest level) or increase

the delivery of the pump that consumes the least (tube with the

highest level).

To vary the delivery of the pumps, rotate slightly in one direction or the other at the injection pumps.

Unscrew the fastening screws of the pump to be adjusted by a quarter of a turn.

Rotating clockwise the delivery is increased, anti-clockwise the delivery is reduced.

Onceadjustmentisnished,tightenthefasteningscrewsto25Nm.

Important

Whenever an injection pump is disassembled or replaced, delivery balancing must be carried out.

Note: A reference notch is located between the pump ange and its mounting on the crankcase. If one or more pumps are

disassembled and reassembled do as follows:

- Makeareferencemarkingonthefasteningangesoftheinjectionpumpsandonthebaseplanesofthecrankcase.

- Leave the shims for injection timing setting under each pump unchanged.

- Each pump should be reassembled in its own housing.

Alignthedeliveryreferencenotcheslocatedonthepumpangewiththoseonthecrankcase.

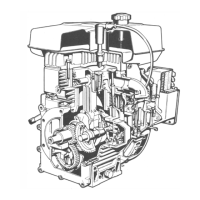

Fuel system

Loading...

Loading...