- 40 - Workshop Manual LDW CHD _ cod. 1.5302.345 - 6° ed_rev. 05

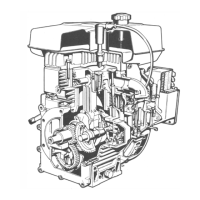

LDW 1503

1603

LDW 2004

2004/T

2204

2204/T

LDW

1503-2004-2004/T

LDW

1603-2204-2204/T

LDW

2004/T-2204/T

LDW

1503-1603

2004-2204

4

64

62

60

59

61

63

Tighteningmustbecarriedoutasshowningure59.

Oncethenaltorque50Nmisreached,waitthirtyminutesbefore

manually rotating the engine to verify that the pistons do not collide

with the valves, if the engine turns freely start the engine normally,

otherwise wait another 30 minutes before repeating the operation.

At rst start-up the engine may run irregularly until all the air

contained in the tappets has been drained.

Disassembly / Reassembly

Connecting rod and piston pin

The connecting rod big end shell bearings are supplied in either

standard or with this value decreased by 0.25 and 0.50 mm

respectively.

Important

The fastening screws must be tightened by hand until the

beginning of the tightening stage and then pre-tightened to

10÷15 Nm.

Final tightening is to 70 Nm.

Connecting rod weights

Connecting rod, piston and piston pin can also be weighed in

a preassembled state but the difference in weigt should not

exceed 14 g in order to avoid unbalance.

Connecting rod

Important

When remounting the big-end bearings, remember to

thoroughly clean the parts and generously lubricate them to

prevent seizure when the engine is started up for the rst

time.

Remove oil pan and oil pump suction pipe.

Disconnect the connecting rod from the engine shaft and

perform the subsequent checks.

When retting both centering notches A and B should be

located on the same side.

Tighten the connecting rod big end bolts to 70 Nm.

Loading...

Loading...