Do you have a question about the Lombardini CHD series and is the answer not in the manual?

Details warranty terms and conditions for Lombardini engines.

Provides notes on using genuine parts and metric format for data.

Defines key terms used in the manual for clarity and understanding.

Outlines essential safety rules and recommendations for operating Lombardini engines.

Provides guidelines for safe engine operation and maintenance procedures.

Addresses the engine's environmental influence and responsible disposal practices.

Lists common engine problems and their potential causes for diagnosis.

Refers to EC approval directives and EPA regulations found on the engine plate.

Details regular maintenance tasks and schedules for the engine.

Details maintenance tasks performed at specific intervals beyond routine checks.

Information on oil classification, specifications, and types.

Explains the SAE system for classifying oil viscosity based on temperature.

Describes API, MIL, and ACEA specifications for lubricants.

Lists recommended lubricants and oil capacities for CHD engines.

Covers coolant type, capacity, and refueling procedures.

Provides guidance on suitable diesel fuels and precautions for storage and use.

Offers essential advice for disassembly and assembly operations.

Offers essential advice for engine overhauls and tuning procedures.

Details the components and cleaning of the oil-bath air cleaner.

Describes the components and cleaning of the dry type air cleaner.

Instructions for refitting the intake manifold gasket.

Instructions for demounting and refitting the exhaust manifold.

Procedure for checking and adjusting 'V' belt tension.

Guidelines for disassembling and checking the cooling fan.

Details torque specifications and refitting for the driving pulley.

Safety precautions and steps for removing the fuel tank.

Safety warnings and procedures for removing the flywheel.

Covers rocker arm covers with air vent and recirculating vent systems.

Instructions for removing and refitting the rocker arm assembly.

Instructions for checking cylinder head plane and warpage.

Details the procedure for removing valves using cotters.

Procedure for checking valve spring free length.

Procedure for checking valve spring length under load.

Provides specifications for valve materials and dimensions.

Discusses valve guides and cylinder head compatibility and dimensions.

Steps for inserting valve guides into the cylinder head.

Steps for installing oil seals in valve guides to prevent warping.

Specifications for valve seats and their bores.

Details valve recess and sealing surface measurements.

Procedure for extracting and replacing the precombustion chamber.

Explains the hydraulic tappet system for valve clearance adjustment.

Illustrates the hydraulic diagram for supplying oil to tappets.

Explains the operating principle and conditions for hydraulic tappets.

Describes the installation and adjustment of the injection pump follower.

Procedure for checking cylinder diameter and wear.

Guidelines for checking and measuring cylinder bore roughness.

Steps for removing piston rings, cleaning, and measuring piston dimensions.

Information on piston oversizes and uprating references.

Instructions for weighing pistons to ensure balance.

Procedure for measuring piston ring end gaps in the cylinder.

Specifications for piston ring clearance within grooves.

Correct sequence and orientation for fitting piston rings.

Steps for connecting piston to connecting rod and installing into cylinder.

Method for measuring piston protrusion and clearance.

Guidance on selecting the correct cylinder head gasket based on piston projection.

Torque specifications for cylinder head bolts on non-hydraulic engines.

Detailed steps and torque values for tightening cylinder head bolts.

Procedure for assembling cylinder head with hydraulic tappets.

Steps for removing and checking connecting rods and big-end bearings.

Instructions for weighing connecting rods, pistons, and pins for balance.

Specifications for connecting rod big end bearings and pin fastening.

Procedure for checking connecting rod alignment using a dial gauge.

Details on the piston cooling sprayer for turbo engines.

Guidance on refitting connecting rod/piston assemblies to original cylinders.

Instructions for correctly installing center main bearings.

Procedure for refitting main bearing caps, including gasket and torque specs.

Procedure for measuring bearing clearance using plastigage.

Information on unified thrust bearings and their interchangeability.

Details on oversized thrust bearings for clearance adjustment.

Procedure for measuring crankshaft end play and fitting oversize thrust bearings.

Steps for replacing crankshaft front and rear oil seals.

Instructions for replacing the crankshaft timing gear, including heating.

Steps for cleaning crankshaft lubrication ducts.

Procedure for measuring main journals and crank pins with a micrometer.

Specifications for main and connecting rod journal diameters.

Dimensions for main and connecting rod bearing inside diameters.

Description of crankshafts for engines with dynamic balancers.

Procedure for adjusting dynamic balancer clearance.

Procedure for removing and refitting the front cover.

Details on the idler gear and hub, including clearance and torque specifications.

Explains the function and components of the speed governor.

Provides dimensions for adjusting the injection pump delivery control yoke.

Details on camshaft gear and governor weight types.

Discusses different types of springs used with speed governors.

Describes the frame and spring for idling speed control.

Tables summarizing governor components based on speed variation.

Explains the function of the starting fuel supply spring.

Main section covering camshaft operations.

Steps for removing the camshaft, including related components.

Procedure for checking camshaft bushing internal diameter.

Specifications for camshaft journals and bushings in LDW 1503.

Specifications for camshaft journals and bushings in LDW 2004/2004-T.

Details the procedure and tool for replacing camshaft bushings.

Specifications for cam heights in LDW 1503 models.

Specifications for cam heights in LDW 2004/2004-T models.

Steps for correctly timing the camshaft.

Method to check valve timing without using timing marks.

Procedure for checking valve timing at the crankshaft.

Valve timing angles for engines with mechanical tappets.

Timing belt operating angles for engines with hydraulic tappets.

Procedure for checking camshaft end play after component removal.

Information on hydraulic pump power take-off options.

Details on GR 1 and GR 2 hydraulic pumps for 3rd PTO.

General information about the turbocharger system.

Lists and identifies the components of the turbocharger.

Procedure for testing the turbocharger's supercharge air pressure.

Procedure for adjusting the turbocharger waste gate actuator.

Diagram illustrating the engine's lubrication system layout.

Details the oil pump components, operation, and capacity.

Specifies how to measure oil pump rotor clearance.

Details the components and checks for the oil pressure adjusting valve.

Provides specifications for the oil filter cartridge.

Procedure for checking engine oil pressure.

Oil pressure curves for LDW 1503-1603 at different engine speeds.

Oil pressure curves for LDW 2004-2204 at different engine speeds.

Oil pressure curves for LDW 2004/T-2204/T at different engine speeds.

Diagram showing the engine's cooling system layout.

Details the expansion tank and its cap features.

Procedure for checking the cooling system for leaks using air pressure.

Instructions for removing and refitting the coolant circulating pump.

Specifications for the engine thermostat.

Illustrates the fuel feeding and injection circuit components.

Details the fuel filter components and specifications.

Describes the diaphragm-type fuel feeding pump.

How to check fuel feeding pump drive rod protrusion and length.

Describes the 24V electric fuel pump for low-temperature starting.

Description of the CHD series injection pump.

Steps for disassembling the injection pump.

Steps for correctly reassembling injection pump components.

Explains the non-return valve in the discharge union.

How the control rod operates and is secured.

Procedure for removing injection pump feeding tubes.

Steps for refitting injection pump feeding tubes.

Describes the tool for equalizing injection pump delivery.

Procedure for balancing injection pump delivery.

Details the plunger and barrel assembly of the injection pump.

Steps for checking injection pump delivery.

Provides test data for injection pump delivery.

Procedure for checking injection timing on engines with hydraulic tappets.

Procedure for checking injection timing on engines with mechanical tappets.

Method to correct injection timing by altering pad thickness.

Lists components of a pin-type injector.

Steps for setting the injector pressure and needle valve seal.

Specifications for Marelli AA 125 R 14V 45A alternator.

Performance curves for Marelli AA 125 R 14V 45A alternator.

Voltage curve for RTT 119 AC regulator.

Specifications for Marelli AA 125 R 14V 65A alternator.

Performance curves for Marelli AA 125 R 14V 65A alternator.

Voltage curve for RTT 119 AC regulator.

Specifications for Iskra AAK3139 14V 80A alternator.

Performance curves for Iskra AAK3139 14V 80A alternator.

Voltage curve for AER 1528 regulator.

Wiring diagram for alternators with 45A / 65A ratings.

Wiring diagram for the preheating control unit.

Specifications for Iskra AAK3570 28V 35A alternator.

Performance curves for AAK3570 28V 35A alternator.

Voltage curve for AER 1528 regulator.

Wiring diagram for 24V systems with a 35A alternator.

Wiring diagram for the preheating control unit.

Details on the 12V Bosch starter motor.

Performance curves for Bosch EV 12V 2.2 kW starter motor.

Shows the electrical layout for the key switch positions.

Details on the 24V Iskra starter motor.

Performance curves for Iskra AZE 4598 24V 3 kW starter motor.

Shows the electrical layout for the key switch positions.

Notes the requirement for a spacer flange for the 24V starter motor.

Describes the pre-heating glow plug components and installation.

Describes the glow plug controller relay and its function.

Details the thermistor's location and resistance characteristics.

Details the coolant high temperature lamp switch characteristics.

Resistance values for the electric thermometer thermistor.

Resistance values for water temp sensors and thermal contacts.

Procedure for setting engine idling speed in no-load conditions.

Procedure for setting engine full speed in no-load conditions.

Method for approximate injection pump delivery setting without a dynamometer.

Function of the delivery limiting and torque adjusting device.

Function of the fuel limiting device for exhaust smoke reduction.

Steps to adjust the fuel limiting device based on temperature.

Procedure for setting the engine stop function.

Diagram for tampering system adjustment on EPA-approved engines.

General guidelines for engine storage periods and conditions.

Steps for protecting the engine during storage.

Procedures to return a stored engine to operational status.

Table of torque specifications for various engine components.

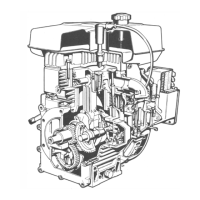

| Engine Type | Diesel |

|---|---|

| Starter | Electric |

| Engine Model | CHD series |

| Cylinders | In-line |

| Number of Cylinders | 2 or 3 |

| Cooling System | Liquid Cooled |

| Aspiration | Natural |

| Governor Type | Mechanical |