HEADER OPERATION

Windrowing

DEUYERY

OPENING

The wkJth and position

of

the delivery openIng

affects

the

width

and configuration

of

thewindrow.

The decision to widen or narrow the center

delivery opening; or whether or not to double

windrow

should

be

based

on

the

following factors:

• combine pick-up capability

• type

and

yield

of

crop

• weather conditions

(rain

humidity, wind)

• drying time available

See

Wmdrow

Characteristics· for the strengths

and

weaknesses

of

the various windrow

configurations

with

respect

to

these factors. See

-Delivery Opening Width" under Operating

Variablesforopeningwidth adjustment procedure.

DECK SHIFr

-

mlPlE

DB.NERY

HEADERS

The triple delivery header allows the operator

10

control deck position and draper rotation from the

wind

rower cab.

see

your

Windrower Tractor

Operator's manual for Identification

of

the

deck

shift

control.

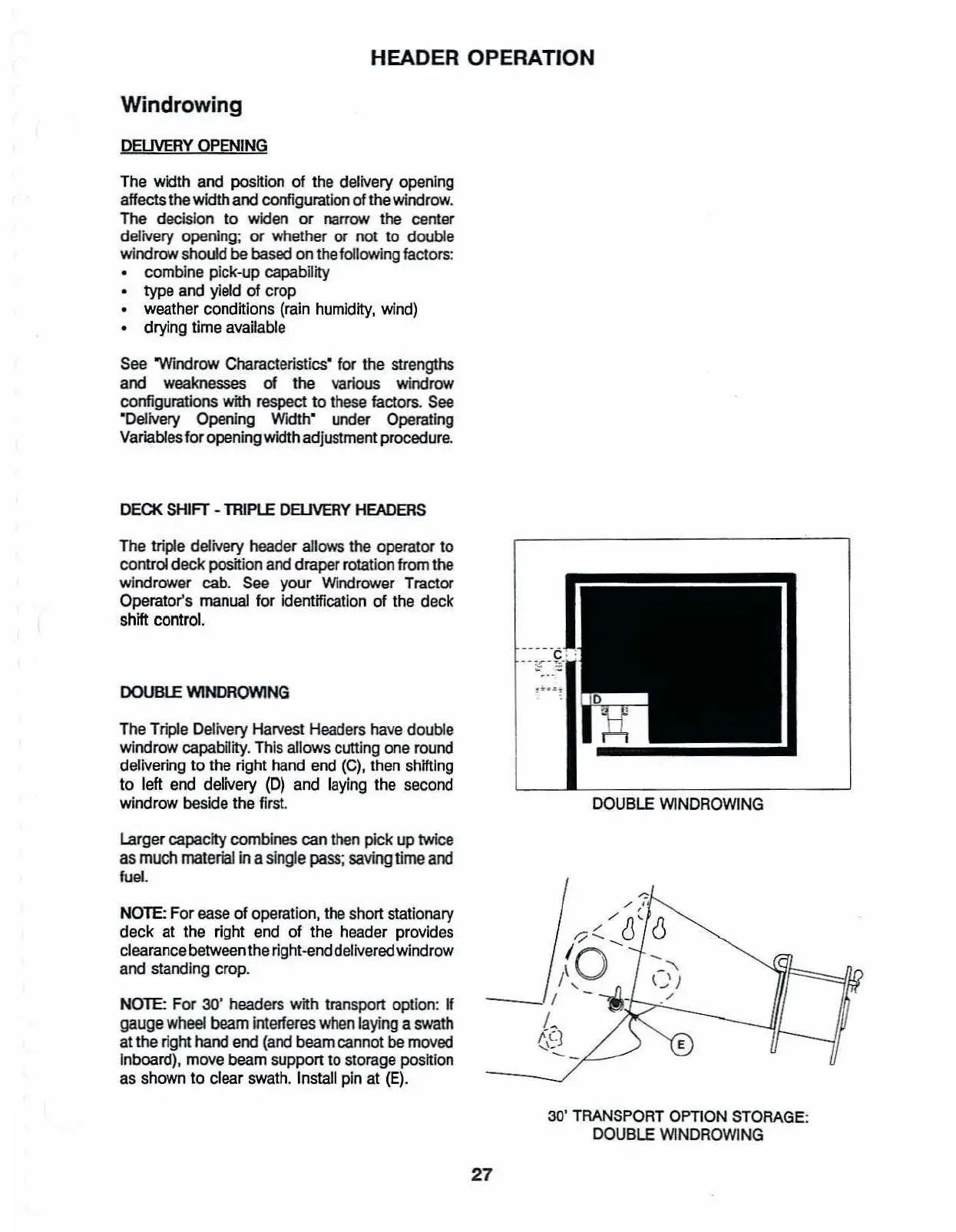

00lJBtE

W1NDROWlNG

The

Triple Delivery Harvest

Headers

have

double

windrow

capability. This allows cutting one round

delivering to the right

hand

end

(C),

then

shiftJng

to left

end

delivery (0)

and

laying

the

second

windrow beside the first.

Larger capacity combines can

then

pick up twice

as

much

material

in a

single

pass;

saving

time

and

fuel.

NOTE: For

ease

ofoperation,

the

short stationary

deck

at

the right

end

of the

header

provides

clearance

between

the right

-end

delivered

windrow

and standing crop.

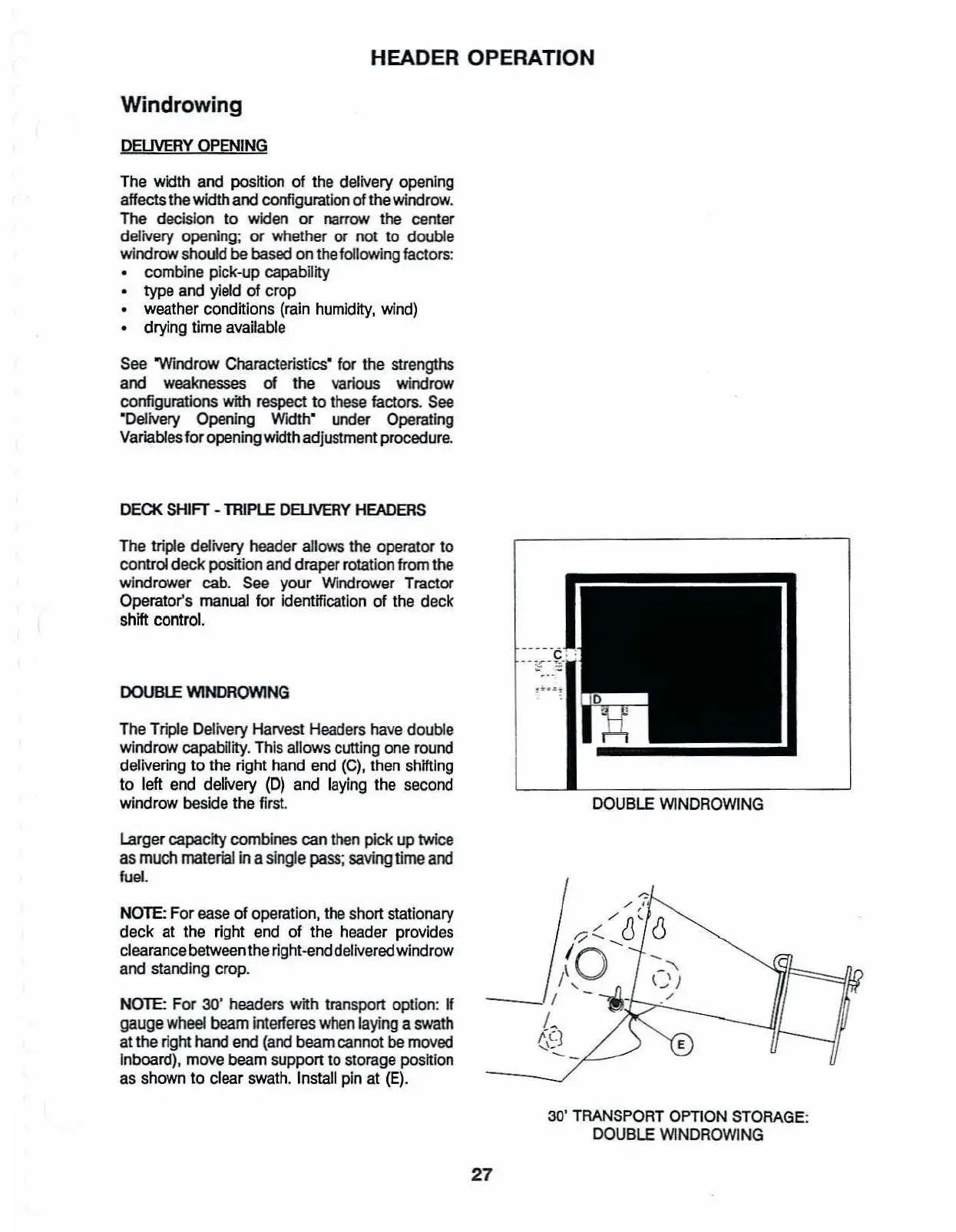

NOTE

For 30' headers with transport option: If

gauge

wheel

beam

interferes

when

laying

a

swath

atthe right hand end

(and

beam cannot

be

moved

Inboard), move

beam

support

to

storage position

as shown to clear

swath.

Install pin

at

(E).

-----t; ,

..

~.~-

...

~.

IIJ!1,rr;-

DOUBLE

WINDROWING

30'

TRANSPORT

OPTION

STORAGE:

DOUBLE

WINDROWING

27

Loading...

Loading...