TRANSPORT

Gauge Wheels

I Transport Option

CONVERTING FROM TRANSPORT TO

FIELD POSITION

(continued)

9.

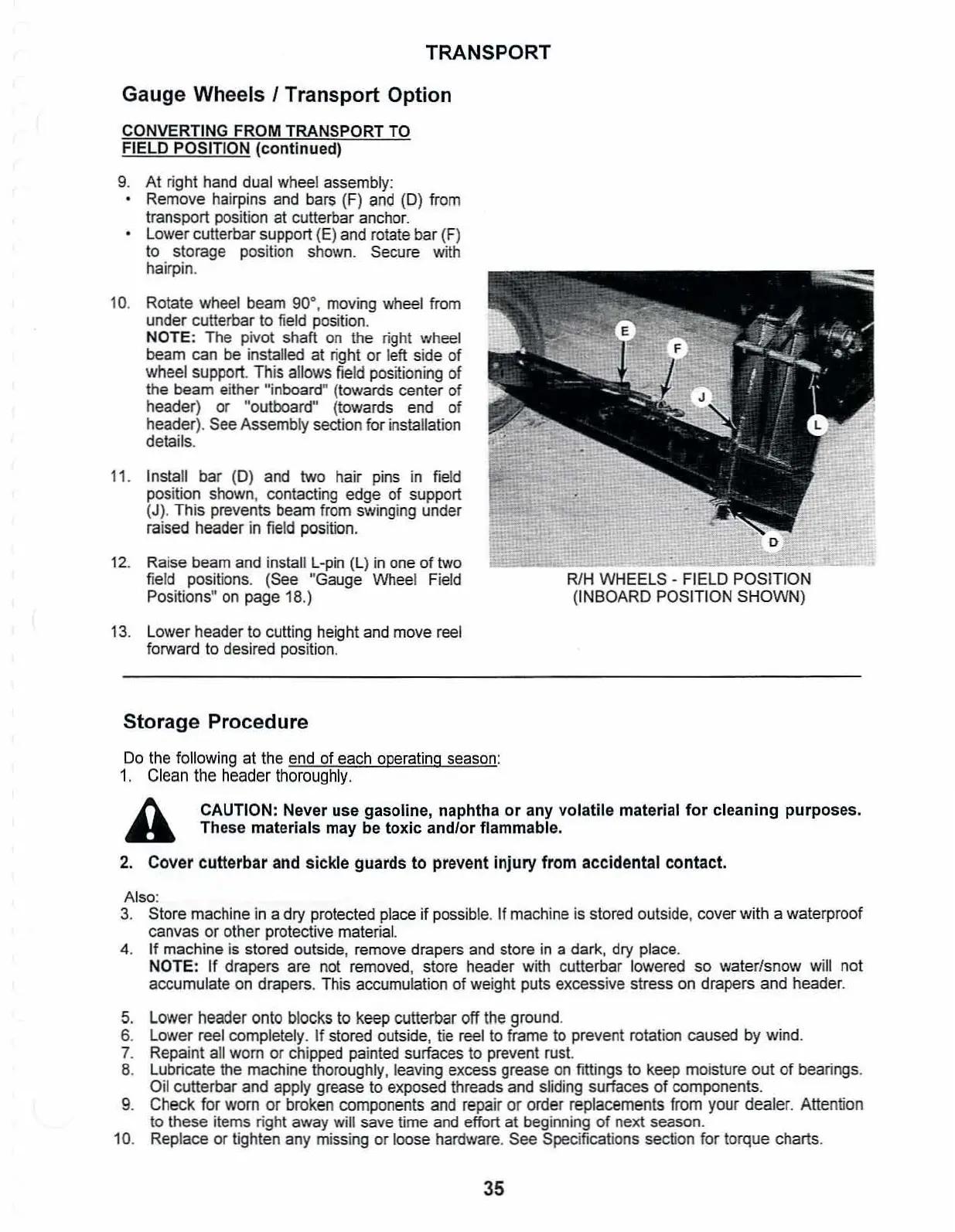

At right hand dual wheel assembly:

Remove hairpins and bars (F) and

(0)

from

transport position at cutterbar anchor.

Lower cutterbar support

(E)

and

rotate bar (F)

to

storage position shown. Secure with

hairpin.

10. Rotate wheel beam 90°. moving wheel from

under cutterbar to field position.

NOTE: The pivot shaft

on

the right wheel

beam can be installed at right or left side

of

wheel

support.

This

allows

field

positioning

of

the beam either "inboard" (towards center of

header) or

"outboard"

(towards

end

of

header).

See

Assembly section for installation

details.

11.

Install bar

(0)

and two hair pins

in

field

position shown, contacting edge of support

(J). This prevents beam from swinging under

raised header in field position.

12. Raise beam and install L-pin (L) in one of two

field positions. (See "Gauge Wheel Field

Positions" on page

18.)

13. Lower header to cutting height and move reel

forward to desired position.

Storage Procedure

RlH WHEELS - FIELD POSITION

(INBOARO POSITION SHOWN)

Do the following at the end of each operating season:

1.

Clean the header thoroughly.

A

CAUTION: Never

use

gasoline,

naphtha

or

any

volatile

material

for

cleaning

purposes.

These

materials

may be

toxic

and/or

flammable.

2.

Cover cutterbar

and

sickle guards to prevent

injury

from accidental contact.

Also:

3.

Store machine in a dry protected place if possible.

If

machine is stored outside, cover with a waterproof

canvas or other protective material.

4.

If

machine is stored outside, remove drapers and store in a

dar1<,

dry place.

NOTE:

If

drapers are not removed, store header with cutterbar lowered so water/snow will

not

accumulate on drapers. This accumulation of weight puts excessive stress on drapers and header.

5.

Lower header onto blocks to keep cutterbar off the ground.

6.

Lower reel completely.

If

stored outside, tie reel to frame to prevent rotation caused by wind.

7.

Repaint all

wom

or

chipped painted surfaces to prevent rust.

8.

Lubricate the machine thoroughly. leaving excess grease on fittings to keep moisture out

of

bearings.

Oil cutterbar and apply grease to exposed threads and sliding surfaces

of

components.

9.

Check for worn

or

broken components and repair or order replacements from your dealer. Attention

to these items right away

will save time and effort at beginning

of

next season.

10. Replace or tighten any missing or loose hardware. See Specifications section for torque charts.

35

Loading...

Loading...