MAINTENANCE/SERVICE

RECOMMENDED

LUBRICANTS

GREASE

Use an SAE Multi·Purpose High Temperature Grease with Extreme Pressure (EP) Petfonnance and

containing at least

1.5% molybdenum disulphide.

Also

acceptable is

an

SAE

Multi-Purpose lithium

Base

Grease.

WOBBlE

BOX

LUBRICANT

In

siclde

drive wobble

box,

use

SAE

85W·140

gear lubricant

(API

Service Classification

GL-S)

CAPAanES:

Wobble

Box·

000

mL

(1.0

U.S.

quart)

STORING

AND

HANDUNG

LUBRICANTS

Your machine can operate

at

top efficiency only

if

clean

lubricants

are

used.

Contaminant in lubricants

is the most likely cause

of

bearing and hydraulic system failure. Use clean containers

to

handle all

lubricants.

Store

lubricants

In

an

area

protected

from

dust,

moisture

and

other

contaminants.

Keep

hydraulic couplers and connectors clean.

SEALED

BEARING

INSTALLATION

1.

Clean shaft and

coat

with

rust preventative.

2.

Install

f1angette.

bearing, flangette and lock

collar.

The

locking

cam

is

only

on

one

side

of

the

bearing.

3.

Install and tighten the flangene bolts.

4.

When

the shaft

Is

located correctly, lock the

lock collar with a punch. The

cotlar should be

locked in the same direction the shaft rotates.

Tighten

the set screw in the collar.

5.

Loosen the flangene bolts on the mating

bearing one turn and re-tighten. this will allow

the bearing to line up.

GREASING

THE

HEADER

See

"Recommended LubrIcants"

In

this section for

recommended greases.

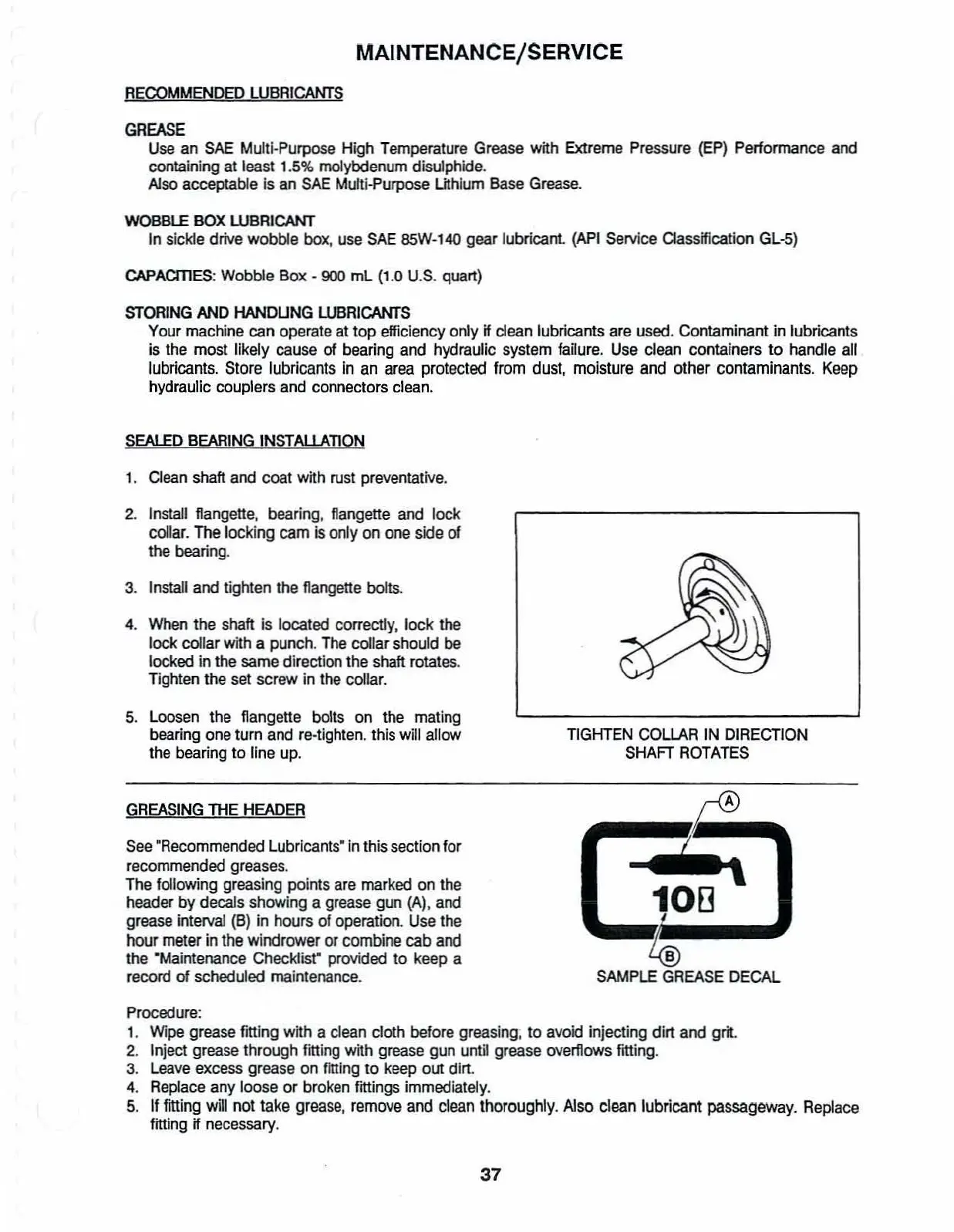

The following greasing points are marked on the

header by decals showing a grease gun (A), and

grease interval

(B)

in hours of operation. Use the

hour meter in the

wioorower or combine cab and

the "Maintenance Checklist" provided

to

keep a

record

of

scheduled maintenance.

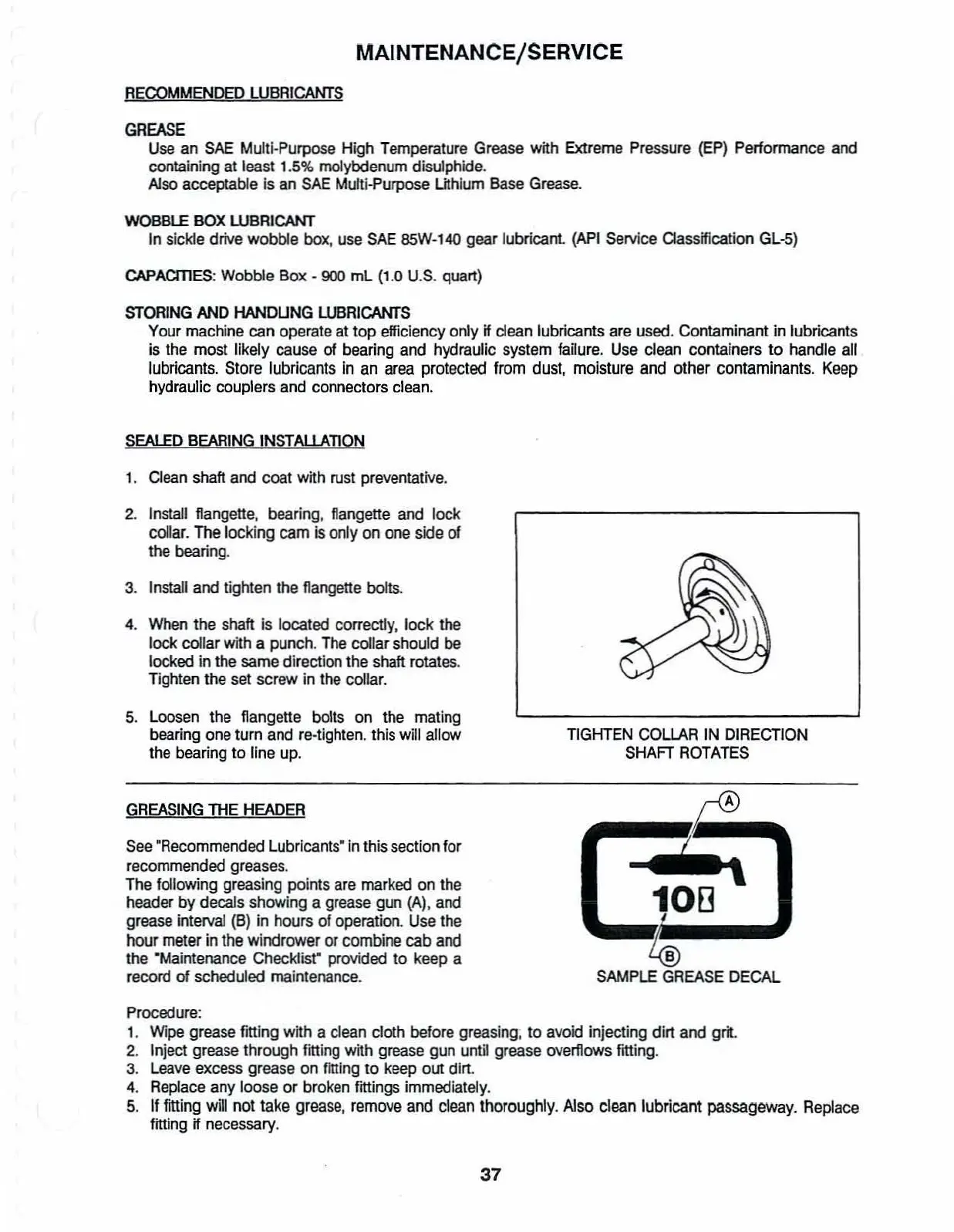

TIGKTEN

COLLAR

IN

DIRECTION

SHAFT

ROTATES

B

SAMPLE

GREASE

DECAL

Procedure:

1.

Wipe grease rmlng with a clean cloth before greasing,

to

avoid injecting dirt and

grit

2.

Inject grease through rmlng with grease gun

unt~

grease overflows fming.

3.

Leave excess grease on fitting

to

keep out dirt.

4.

Replace any loose

or

broken rmings immediately.

5.

If fining

wm

not take grease, remove and clean thoroughly. Also clean lubricant passageway. Replace

fitting

if

necessary.

37

Loading...

Loading...