MAINTENANCE/SERVICE

GREASING THE HEADER (continued)

500

Hours

or

Annually

,.

Gauge Wheel

Hub

Bearings

(G)

-

one fitting per wheel

GAUGE WHEEL HUB BEARINGS

HYDRAULIC SYSTEM

Hydraulic

Hoses

and

Unes

A

Cheek hydraulic hoses and lines daily for signs

of

leaks.

WARNING: Avoid

high-pressure

fluids.

Escaping

fluid

can penetrate

the

skin

causing

serious

injury.

Relieve

pressure

before

disconnecting

hydraulic

lines. Tighten all connections before applying

pressure. Keep hands and

body

away

from

pin-holes

and

nozzles

which

eject

fluids

under

high

pressure. Use a

piece

of

cardboard

or

paper

to

search

for

leaks. IF ANY

fluid

is

injected

into

the

skin,

it

must

be

surgically

removed

within

a

taw hours by a

doctor

familiar with this type of injury or

gangrene

may

result.

AVOID

HIGH-PRESSURE FLUIDS

IMPORTANT:

• Ensure all hydraulic couplings are fully engaged before operating header.

• Keep hydraulic coupler tips and connectors clean. Dust, dirt, water and foreign

material are the major causes

of

damage to the hydraulic system.

• To prevent improper mixing of oils: If header is to be switched back and forth

from combine to windrower, change oil in Windrower Tractor (or Bi-Directional

Tractor) hydraulic system and in Combine Adapter hydraulics reservoir to match

Combine hydraulic system. See your Tractor and Combine Operator's Manuals

for total hydraulic system care.

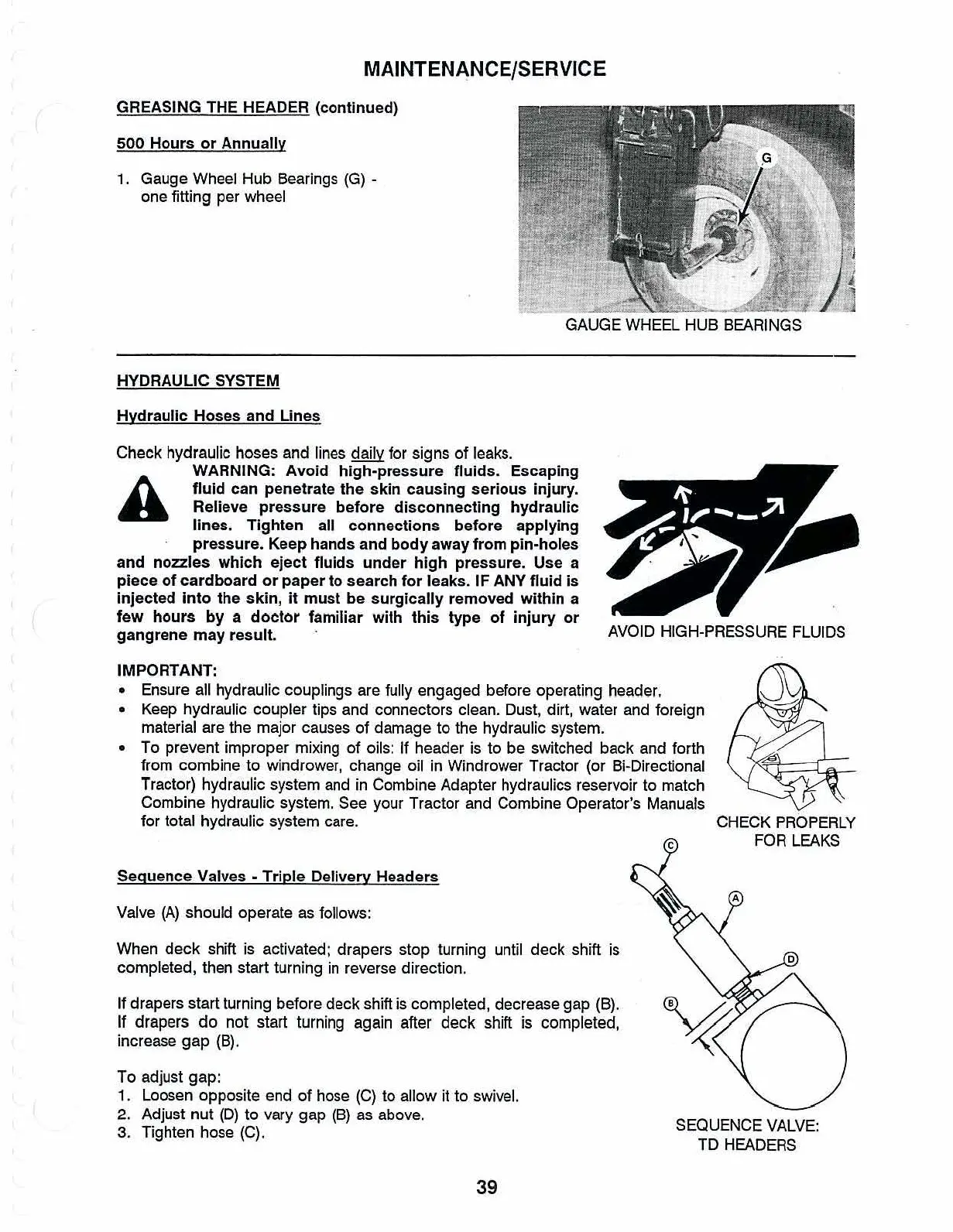

Sequence

Valves -

Triple

Delivery Headers

Valve

(A)

should operate as follows:

When

deck

shift

is

activated; drapers stop turning until deck shift is

completed, then start turning

in

reverse direction.

If drapers start turning before deck shift is completed, decrease gap (6).

If drapers

do

not start turning again after deck shift is completed,

increase

gap

(8).

To adjust gap:

1. Loosen opposite end

of

hose (e) to allow it to swivel.

2. Adjust nut

(D)

to vary gap (8)

as

above.

3. Tighten hose

(C).

39

CHECK PROPERLY

FOR LEAKS

SEQUENCE VALVE:

TD HEADERS

Loading...

Loading...