MAINTENANCE/SERVICE

SICKLE AND SICKLE DRIVE (continued)

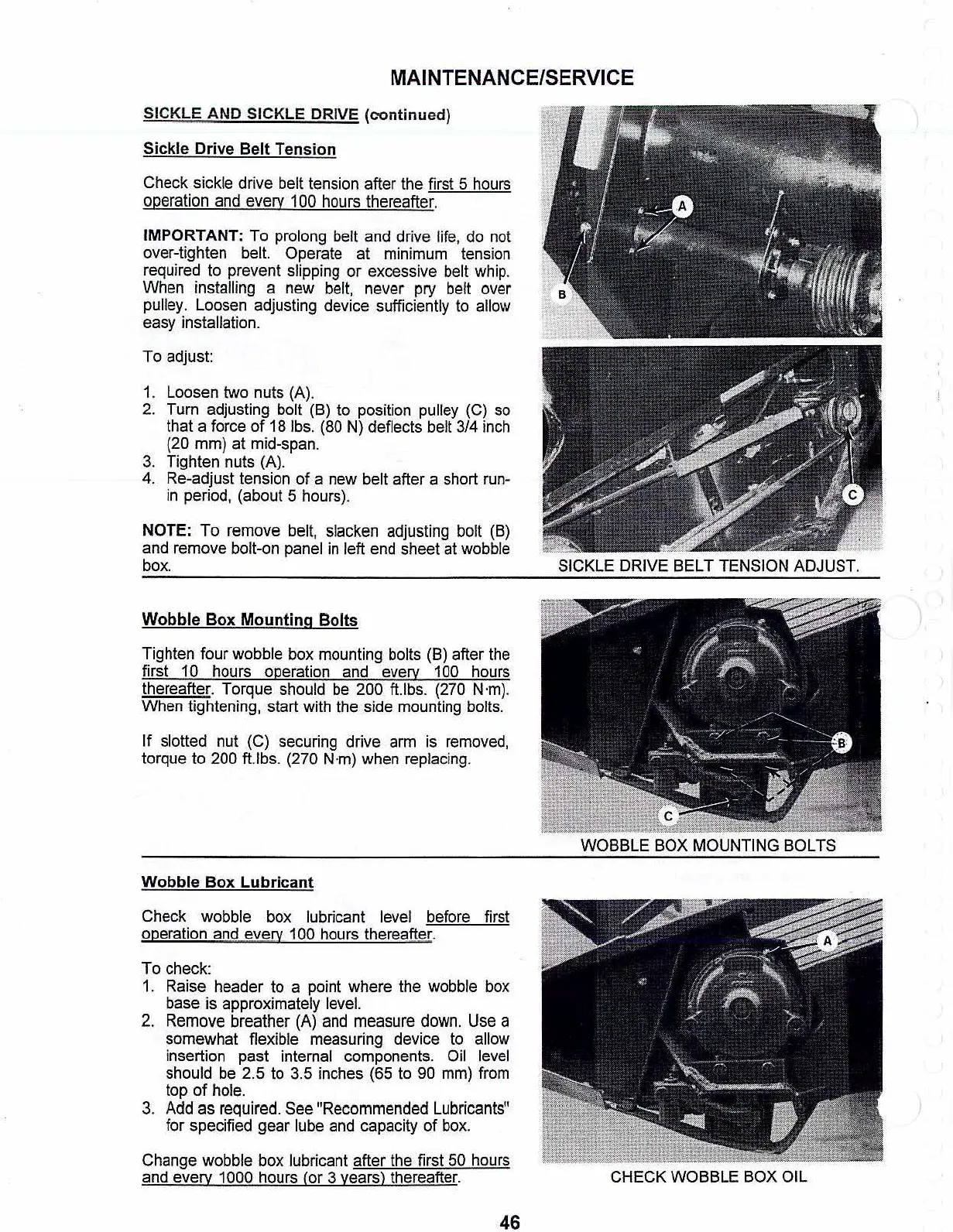

Sickle Drive Belt Tension

Check sickle drive belt tension after the first 5 hours

operation

and

every

100

hours

thereafter.

IMPORTANT: To prolong belt and drive life, do not

over-tighten belt. Operate at minimum tension

required to prevent slipping

or

excessive belt whip.

When

installing

a

new

belt,

never

pry

belt

over

pUlley. Loosen adjusting device sufficiently to allow

easy installation.

To adjust:

1.

Loosen two nuts (A).

2.

Turn adjusting bolt

(B)

to position pulley (C)

so

that a force

of

18

Jbs.

(80 N) deflects belt 3/4 inch

(20

mm)

at

mid-span.

3.

Tighten nuts (A).

4.

Re-adjust tension

of

a new belt after a short run-

in

period, (about 5 hours).

NOTE:

To

remove belt, slacken adjusting bolt (B)

and remove bolt-on panel

in

left

end

sheet at wobble

box.

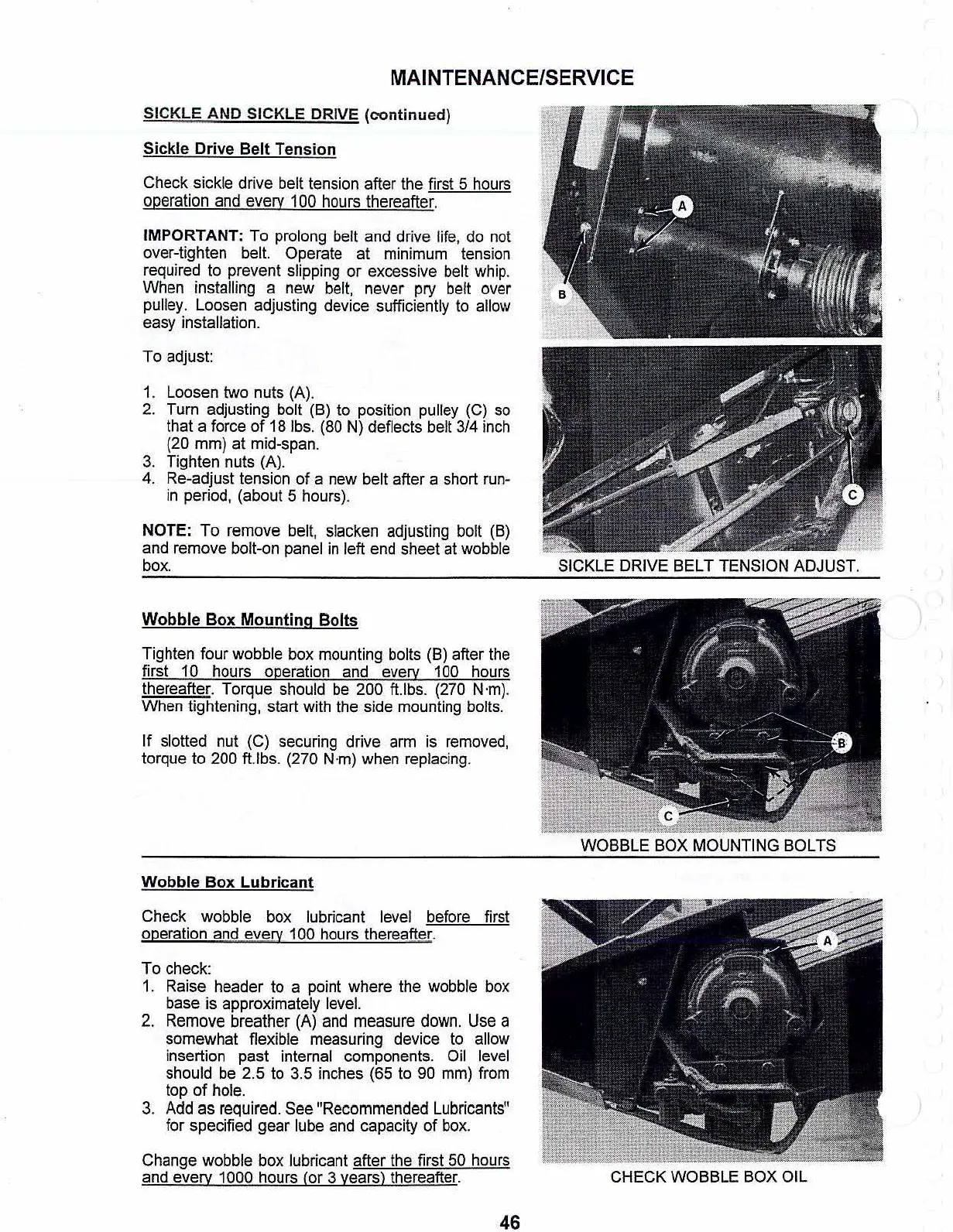

Wobble Box Mounting Bolts

Tighten four wobble box mounting bolts (8) after

the

first 10 hours operation

and

every

100

hours

thereafter. Torque should

be

200 ft.lbs.

(270

N·m).

When tightening, start with

the

side mounting

bolts.

If slotted nut (C) securing drive arm

is

removed,

torque to 200 ft.lbs. (270 N'm) when replacing.

Wobble Box Lubricant

Check wobble box lubricant level before first

operation and every

100

hours thereafter.

To check:

1.

Raise header to a point where

the

wobble box

base is approximately level.

2. Remove breather

(A)

and

measure down.

Use

a

somewhat flexible measuring device

to

allow

insertion past internal components.

Oil

level

should

be

2.5

to

3.5 inches (65

to

90

mm)

from

top

of

hole.

3.

Add

as required. See "Recommended Lubricants"

for specified gear

lube

and

capacity of

box.

Change wobble box lubricant after the first

50

hours

and

every 1000 hours (or 3 years) thereafter.

46

SICKLE DRIVE

BELT

TENSION ADJUST.

WOBBLE

BOX MOUNTING BOLTS

CHECK

WOBBLE

BOX

Oil

Loading...

Loading...