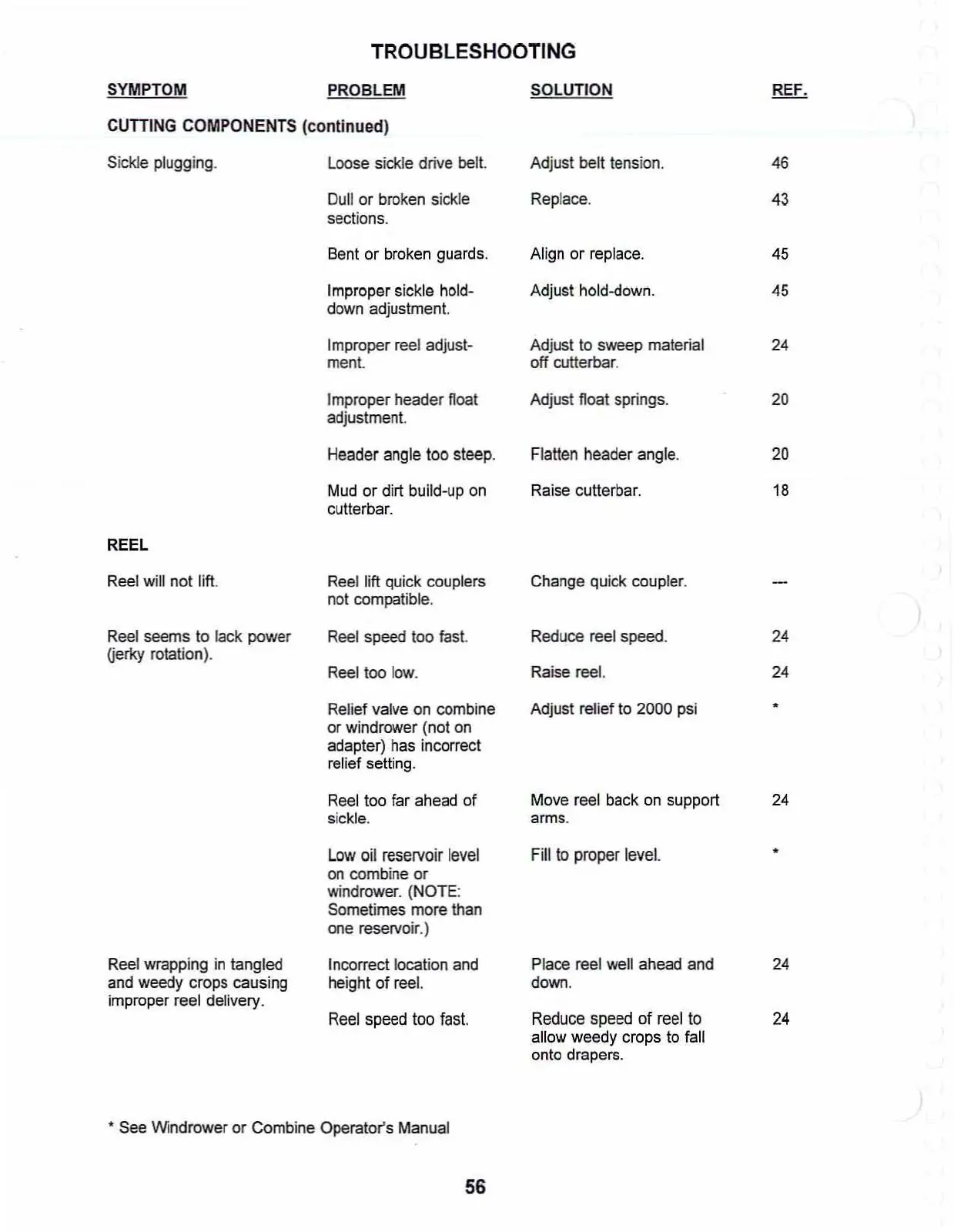

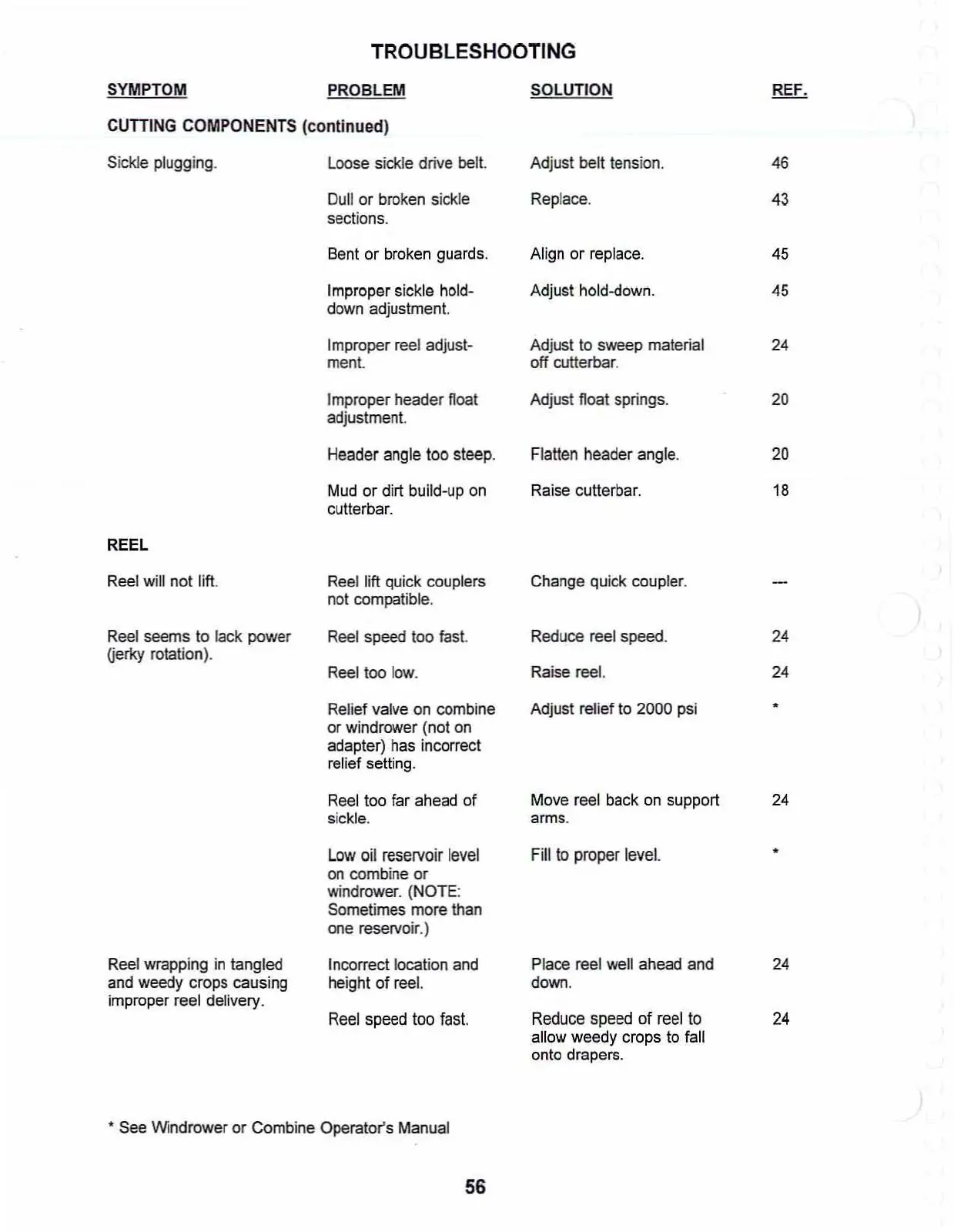

TROUBLESHOOTING

SYMPTOM

PROBLEM

SOLUTION

REF.

CUnlNG

COMPONENTS

(continued)

Sickle plugging.

Loose sickle drive belt.

Adjust belt tension.

46

Dull or broken sickle

Replace,

43

sections.

Bent

or

broken

guards.

Align

or

replace.

45

Improper

sickle

hold-

Adjust

hold-down.

45

down adjustment.

Improper reel adjust- Adjust to sweep material

24

menl

off

cutterbar.

Improper header float Adjust float springs.

20

adjustment.

Header

angle

too

steep.

Flatten

header

angle.

20

Mud

or dirt build-up

on

Raise

cutterbar. 18

cutterbar.

REEL

Reel will not lift.

Reel

lift quick couplers Change quick coupler.

not compatible.

Reel seems to lack power

Reel

speed

too

fast.

Reduce

reel

speed.

24

Oerky

rotation).

Reel

too

low.

Raise

reel.

24

Relief valve on combine

Adjust relief to 2000 psi

•

or windrower (not

on

adapter)

has

incorrect

relief setting.

Reel

too far

ahead

of

Move

reel

back

on

support

24

sickle.

arms.

Low

oil reservoir level

Fill

to proper

level.

•

on

combine or

windrower. (NOTE:

Sometimes more

than

one reservoir.)

Reel

wrapping

in

tangled

Incorrect location

and

Place reel well ahead and

24

and

weedy crops causing

height of

reel.

down.

improper reel delivery.

Reel

speed

too

fast.

Reduce

speed of reel to

24

allow

weedy crops to

fall

onto drapers.

..

See

Windrower or Combine Operator's

Manual

56

Loading...

Loading...