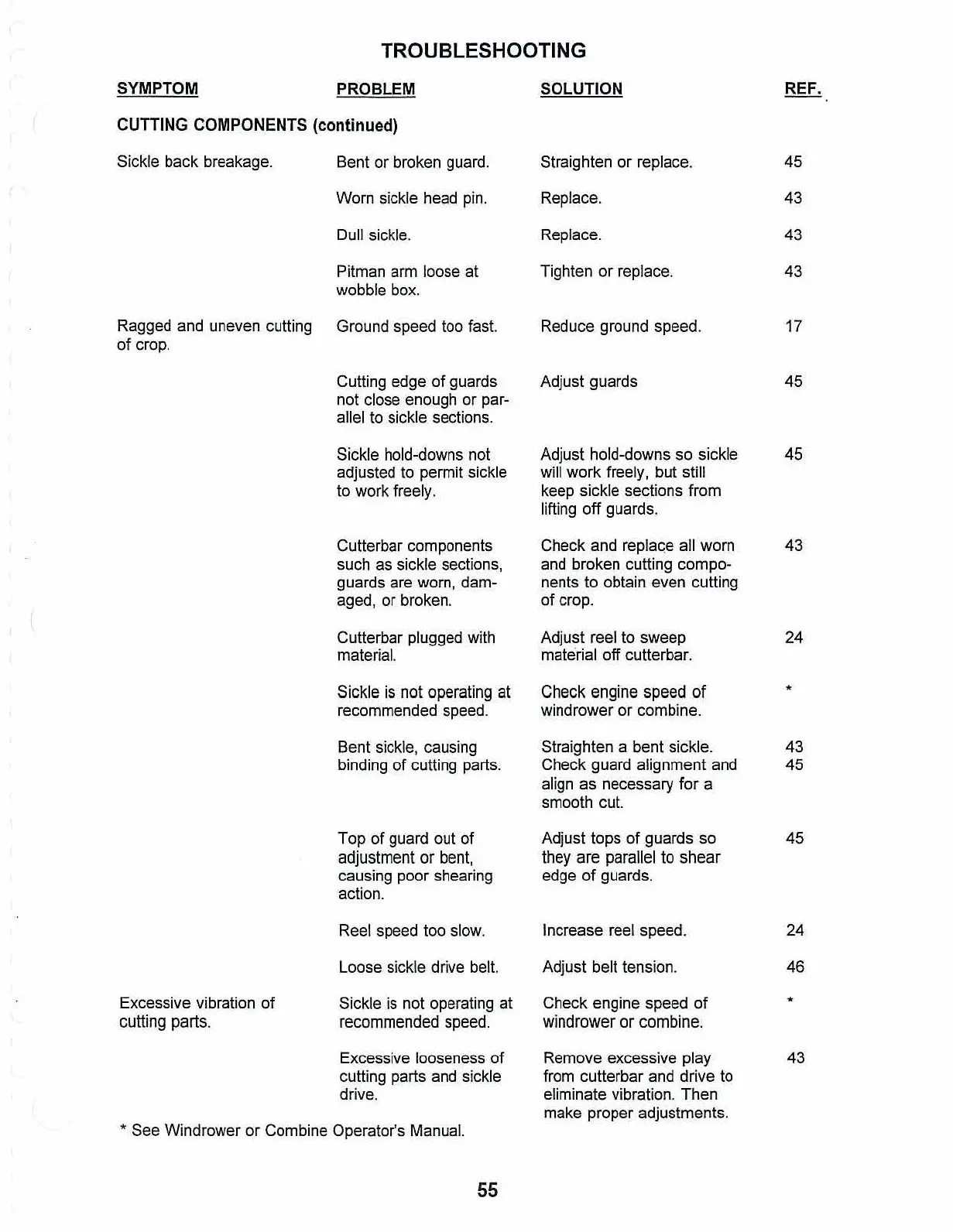

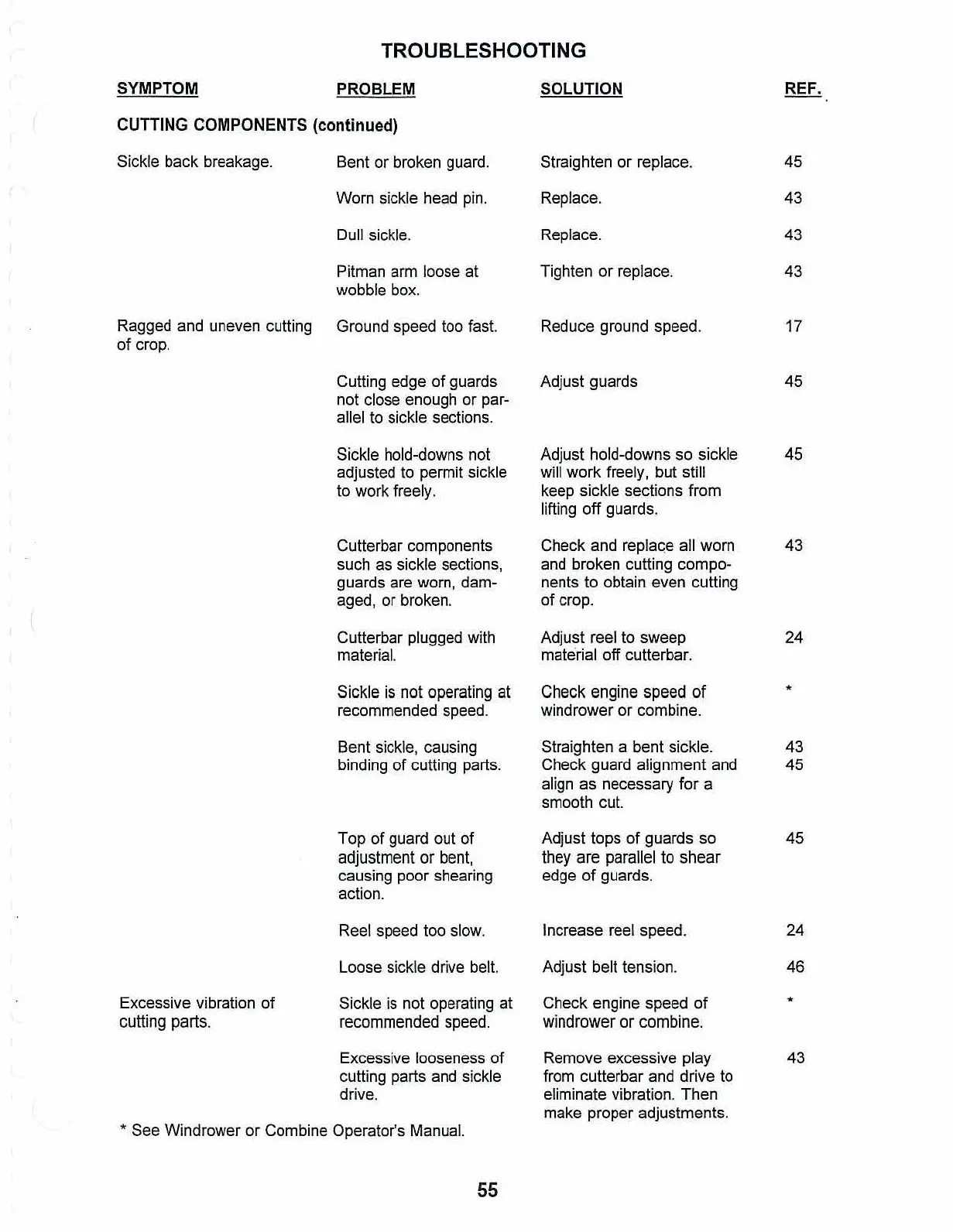

TROUBLESHOOTING

SYMPTOM

PROBLEM SOLUTION REF.

CUTIING

COMPONENTS

(continued)

Sickle back breakage. Bent or

broken

guard.

Straighten or replace. 45

Worn sickle head

pin.

Replace.

43

Dull

sickle.

Replace.

43

Pitman arm loose al

Tighten or replace.

43

wobble

box.

Ragged and uneven cutting

Ground

speed

too

fast.

Reduce ground speed.

17

of

crop.

Cutting edge

of

guards Adjust guards

45

not close enough or par-

allel

to

sickle sections.

Sickle

hold-downs

not

Adjust hold-downs

so

sickle

45

adjusted to permit sickle will work freely, but still

to work freely. keep sickle sections from

lifting off guards.

Cutterbar components

Check and replace all worn 43

such

as

sickle sections, and broken cutting compo-

guards are worn, dam- nents to obtain even cutting

aged,

or

broken.

of crop.

Cutterbar plugged with Adjust reel to sweep

24

material.

material off cutterbar.

Sickle is not operating at Check engine speed of

•

recommended speed. windrower

or

combine.

Bent sickle, causing

Straighten a bent sickle.

43

binding of cutting parts. Check guard alignment and

45

align as necessary for a

smooth cut.

Top of guard out of Adjust tops

of

guards so

45

adjustment or bent,

they are parallel to shear

causing poor shearing edge

of

guards.

action.

Reel speed too slow.

Increase reel speed.

24

Loose sickle drive belt. Adjust belt tension.

46

Excessive vibration of

Sickle is not operating at

Check engine speed of

•

cutting parts.

recommended speed. windrower or combine.

Excessive looseness

of

Remove excessive play

43

cutting parts and sickle from cutterbar and drive to

drive. eliminate vibration. Then

make proper adjustments.

* See Windrower

or

Combine Operator's Manual.

55

Loading...

Loading...