UNLOADING & ASSEMBLY

LOWER

HEADER

E

o

I I I ,

I I I 1

I I I I

I

I

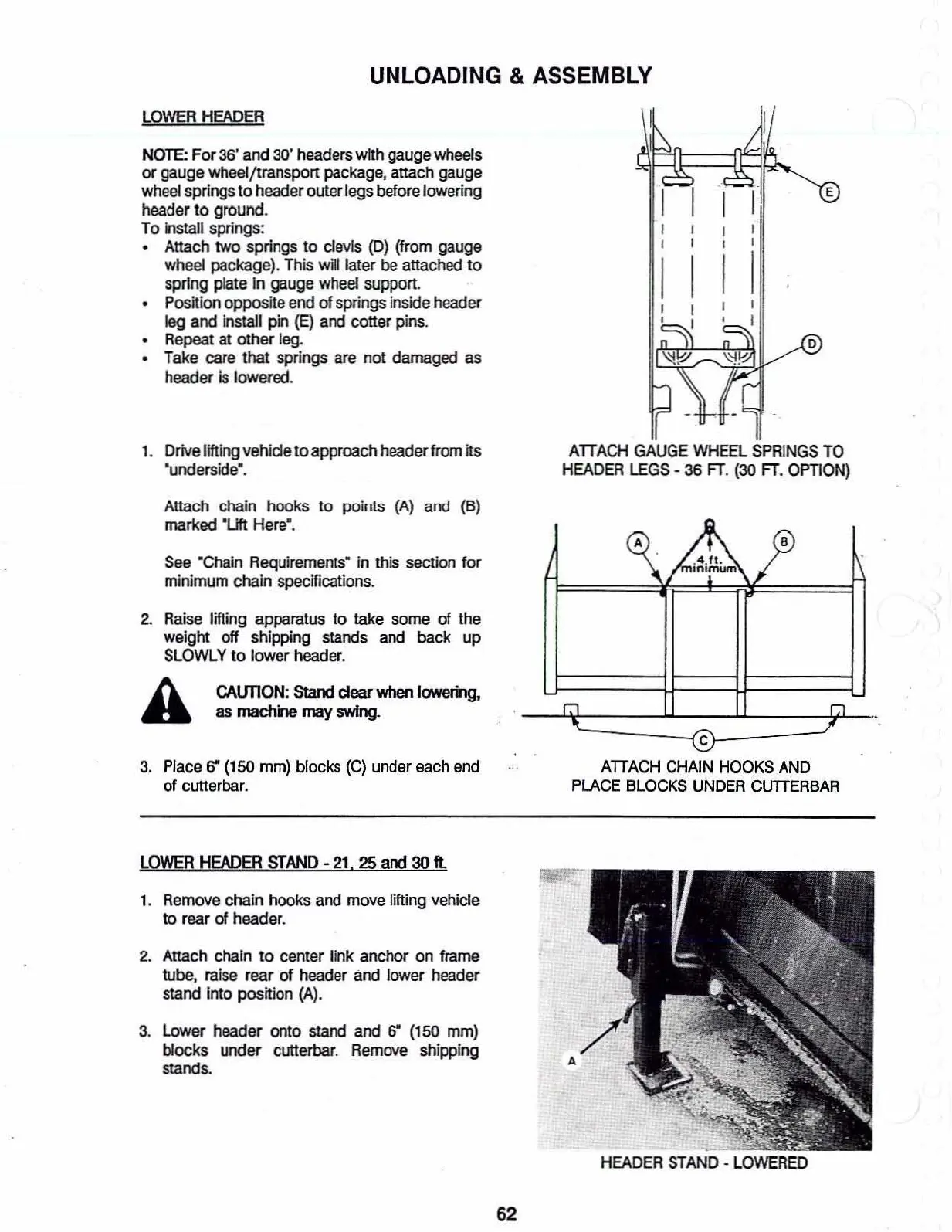

NOTE:

For36' and 30' headers with gauge wheels

or gauge wheeljtransport package. attach gauge

wheel springs toheader outerlegs beforelowering

header

to

ground.

To

install springs:

• Attach

two

springs

to

clevis (0) (from gauge

wheel package). This

wRl

later

be

attached to

spring

plate

in

gauge

wheel

support.

Position

opposite

end

of

springs

Inside

header

leg

and

install pin

(E)

and cotler pins.

• Repeat

at

other leg.

• Take care

that

springs afe not damaged as

header is lowered.

1.

Drive

lifting vehicle

to

approach

header

from

hs

·underslde"

.

ATTACH

GAUGE

WHEEL

SPRINGS

TO

HEADER

LEGS

-

36

FT.

(30

FT.

OPTION)

Attach

chain hooks to points

(A)

and

(6)

marked "Uft Here",

See ·Chaln Requirements" in this section for

minimum

chain specifications.

2.

Raise

lifting apparatus to

take

some of the

weight off shipping stands

and

back up

SLOWLY

to

lower header.

A

CAtmON: Stand

clear

when

lowering,

as

machine may swing.

3.

Place

6"

(150 mm) blocks

(C)

under each end

of

cunerbar.

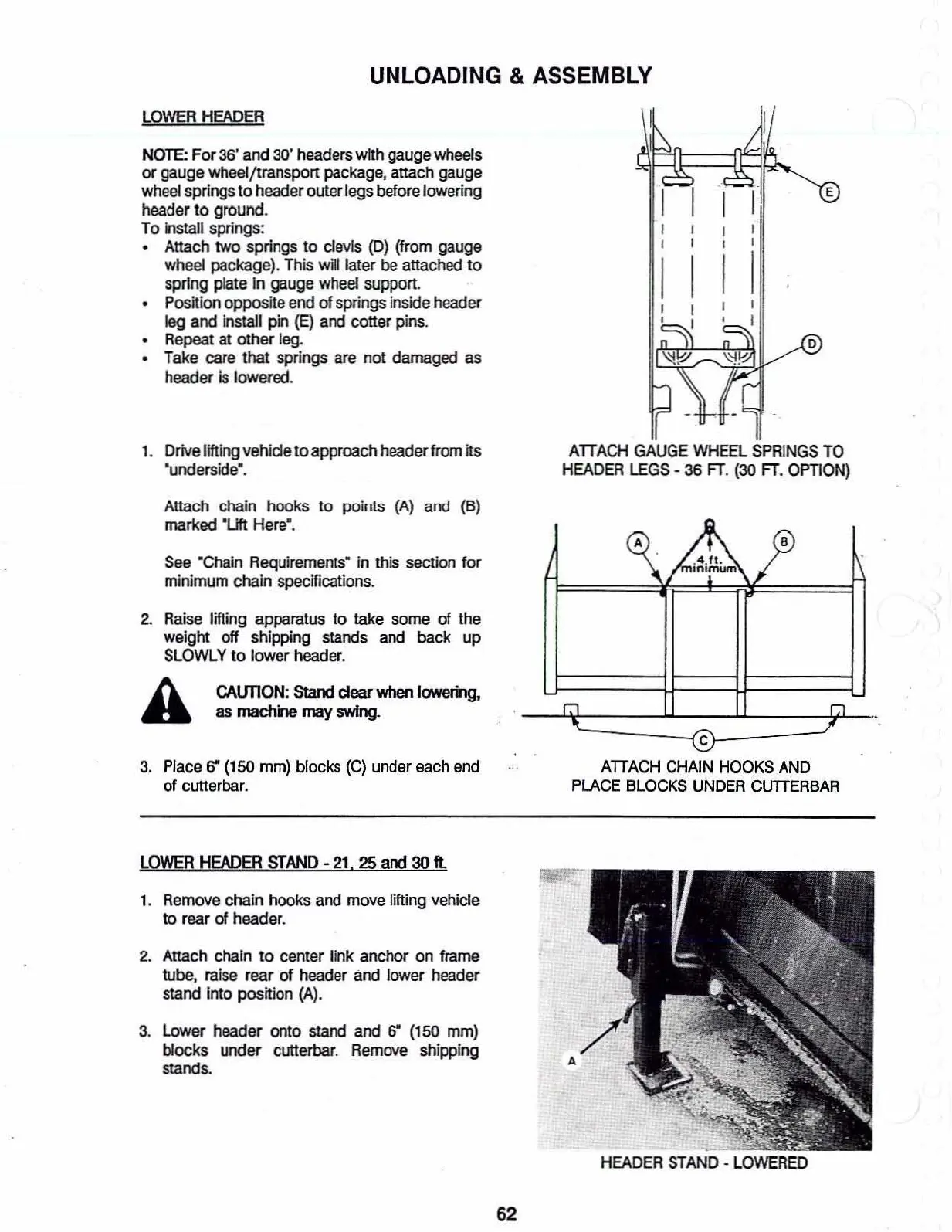

c

ATTACH

CHAIN

HOOKS

AND

PLACE

BLOCKS

UNDER

CUTTERBAR

LOWER

HEADER

STAND

- 21.25

and

30

II.

1.

Remove chain hooks and move lifting vehicle

to

rear

of

header.

2.

Attach chain

to

center link anchor

on

frame

tube. raise rear

of header and lower header

stand

Into pashian

(Al.

3.

Lower header onto

stand

and

6"

(150

mm)

blocks under

cunerbar.

Remove

shipping

stands.

HEADER

STAND

-

LOWERED

62

Loading...

Loading...