MAINTENANCE/SERVICE

SICKLE

AND

SICKLE DRIVE

(continued)

B

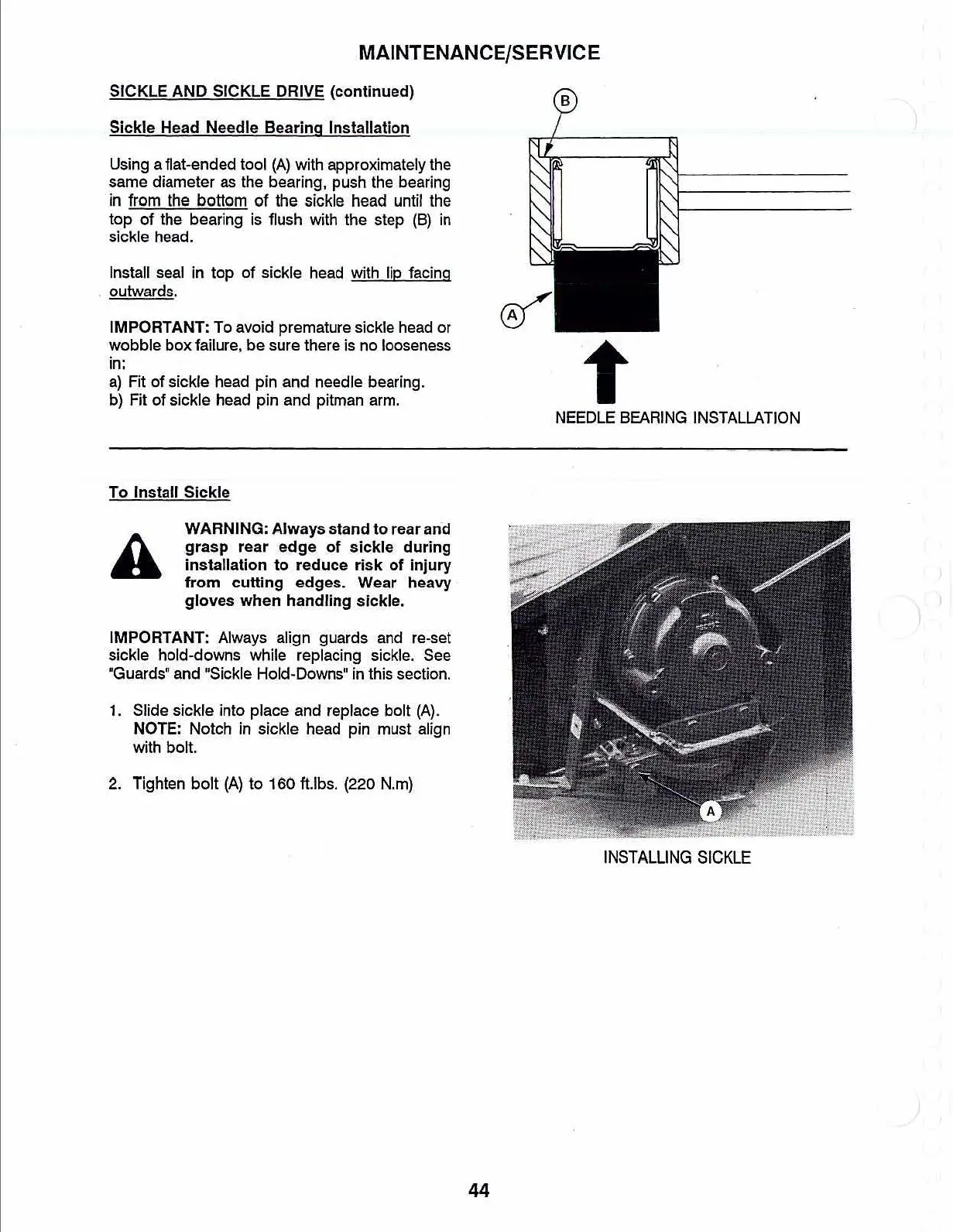

Sickle Head Needle Bearing Installation

Using a flat-ended tool

(A)

with approximately the

same diameter as the bearing, push the bearing

in from

the

bottom of the sickle head until the

top

of

the bearing is flush with the step (8) in

sickle head.

Install seal in

top

of sickle head with lip facing

outwards.

IMPORTANT:

To

avoid

premature

sickle head

or

wobble

box failure,

be

sure there is no looseness

in:

a)

Fit of sickle head pin and needle bearing.

b) Fit

of

sickle head pin and pitman arm.

t

NEEDLE

BEARING

INSTALLATION

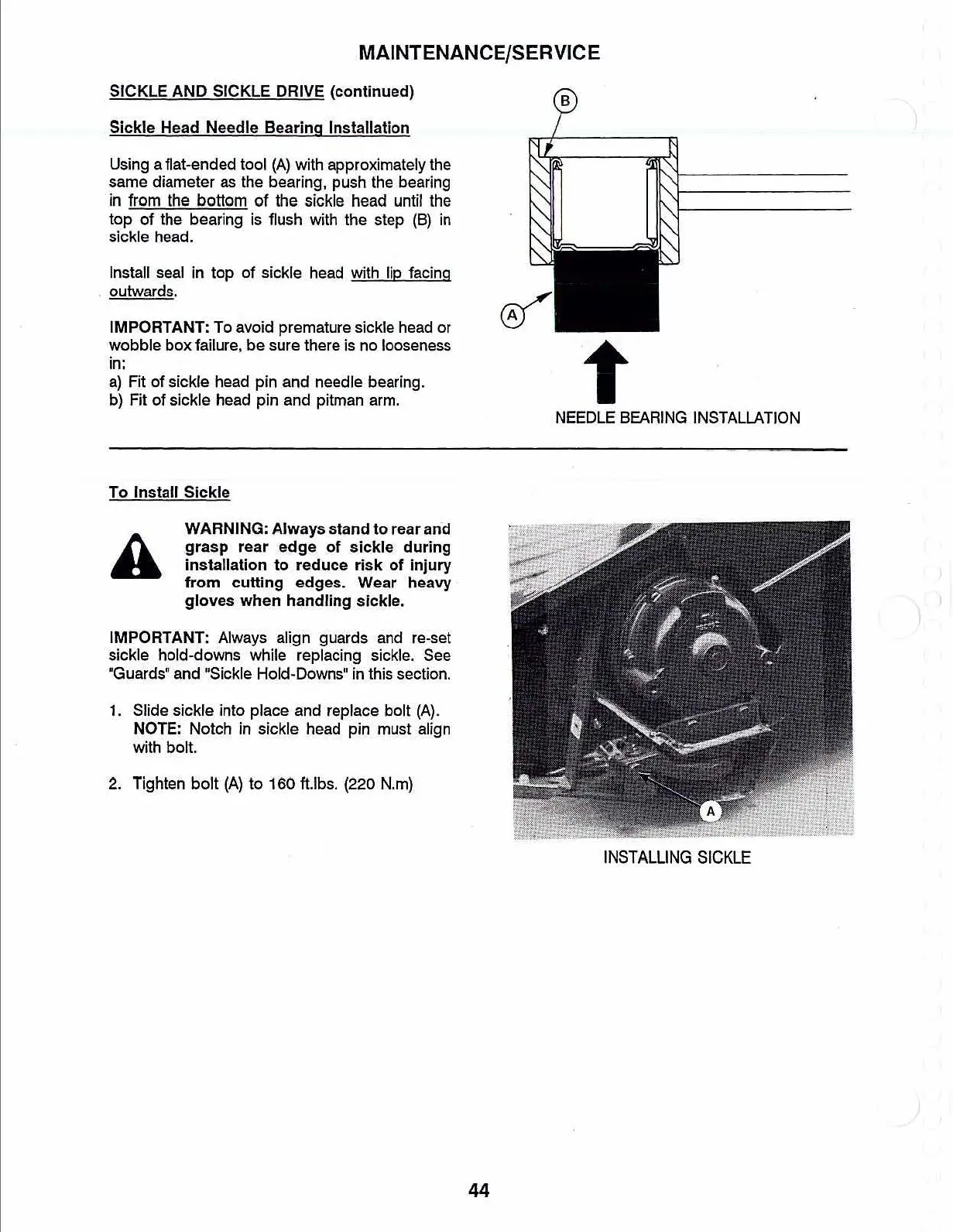

To

Install

Sickle

2.

Tighten bolt

(A)

to 160 ft.lbs. (220

N.m)

1. Slide sickle into place and replace bolt

(A).

NOTE: Notch

in

sickle head pin must align

with bolt.

IMPORTANT: Always align guards and re-set

sickle hold-downs while replacing sickle. See

-Guards· and -Sickle Hold-Downs" in this section.

WARNING:

Always

stand

to

rear and

grasp

rear

edge

of

sickle

during

installation

to

reduce

risk

of

injury

from

cutting

edges.

Wear heavy

gloves

when

handling

sickle.

A

INSTALLING

SICKLE

44

Loading...

Loading...