12 EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com

4.2 Principle

The M&C gas cooler EC-30C is a two stage combination of compressor and Peltier cooler.

The automatic defrost function of the dual deep freezer unit ensures 100 % availability

during operation.

The micro processor-controlled electronics of the EC-30C in combination with the graphi-

cal display, offers a high degree of functionality, convenience in use, and safe operation.

The EC-30C is built for 24/7 hours of operating time. The cooling capacity of 130 kJ/h is

constant, even under maximum allowed ambient temperature.

A capacity reserve compensates parts of the natural aging process and maximizes the

service life of the EC-30C.

The pre-cooler unit is equipped with a Jet-Stream heat exchanger. The heat exchanger is

cooled down to the constant temperature of +2 °C (35.6 °F) by a separate, microprocessor

controlled, compressor cooling unit.

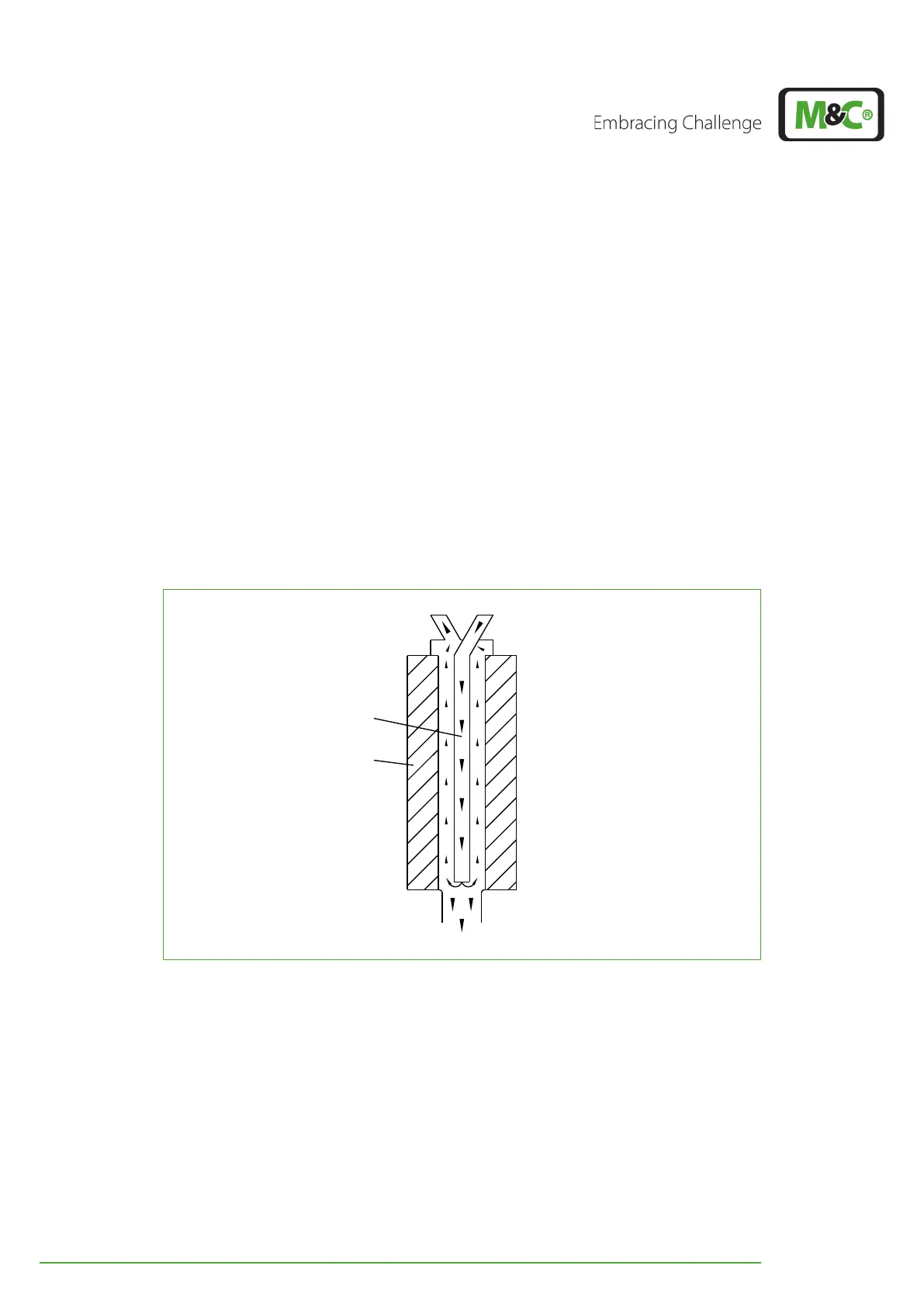

M&C Jet-Stream

heat exchanger

Cooling block

Condensate - OUT

Sample gas - IN

Sample gas - OUT

Fig. 2: Jet-Stream heat exchanger

The Jet-Stream heat exchanger in the pre-cooler unit removes a large amount of conden-

sate, this ensures a safe and reliable pre-drying of the sample gas. An additional external

vessel to separate the condensate is under normal conditions not necessary. The cooling

unit of the pre-cooler dissipates the heat of the Peltier elements.

The dual deep freezer unit is equipped with two modified Jet-Stream heat exchangers.

Two separate pairs of Peltier elements are cooling the heat exchangers down to a constant

temperature between -20 °C (~-4 °F) and -30 °C (~-22 °F). The factory setting is -30°C (~-22

°F).

Loading...

Loading...