Published 3-30-2018, CTRL 636-05 6-13

CD15 OPERATOR MANUAL MAINTENANCE

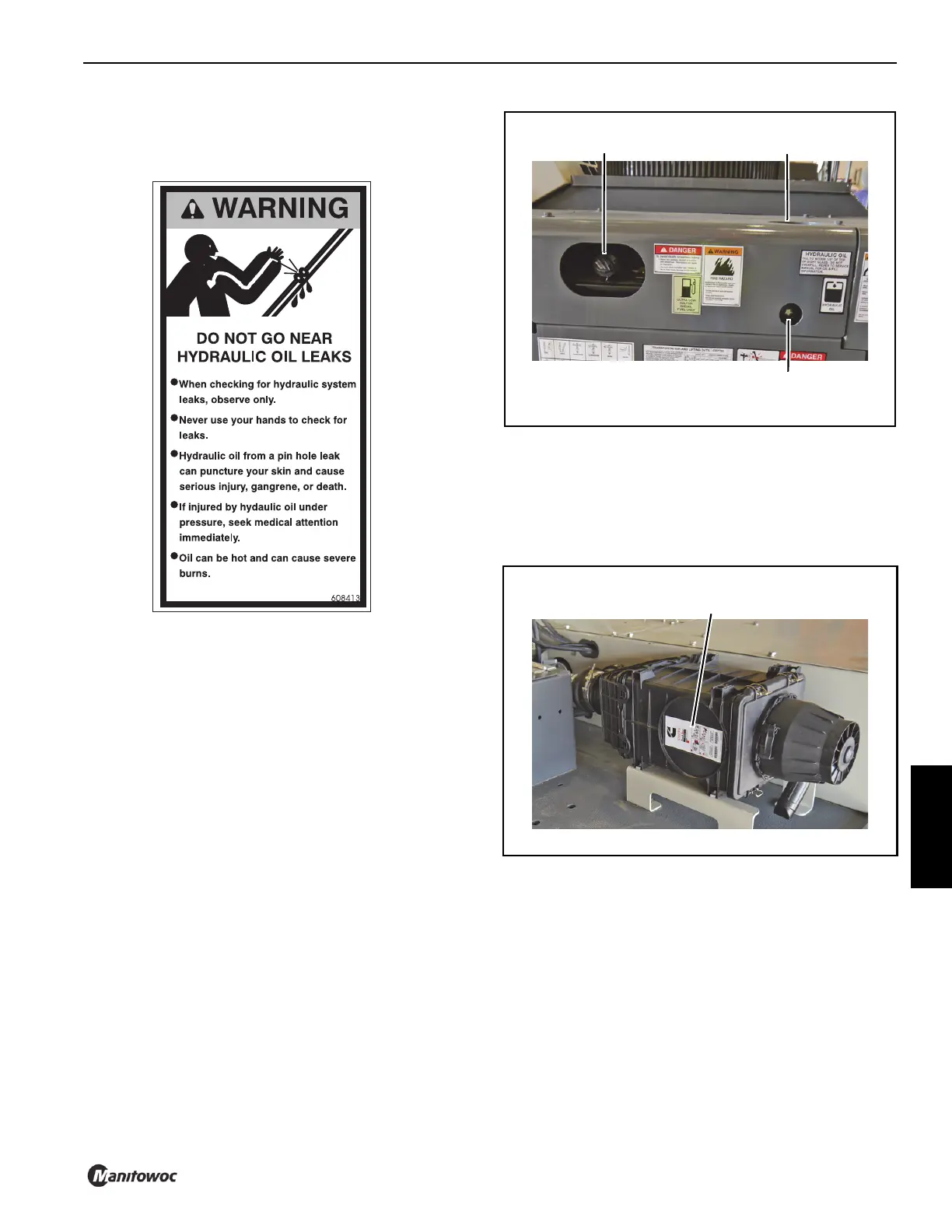

Check Hydraulic Oil Level

If the hydraulic oil is consistently low, check for leaks in the

hydraulic system.

1. Be sure the boom is fully retracted and lowered and the

outriggers are retracted and up.

2. Level the crane, engage the parking brake and stop the

engine.

3. Visually check the oil level on the hydraulic oil level sight

gauge (Figure 6-11). The hydraulic oil should be 3 mm

(0.125 in) from the top of the sight gauge. If low, fill tank

with clean recommended hydraulic oil (Section 8).

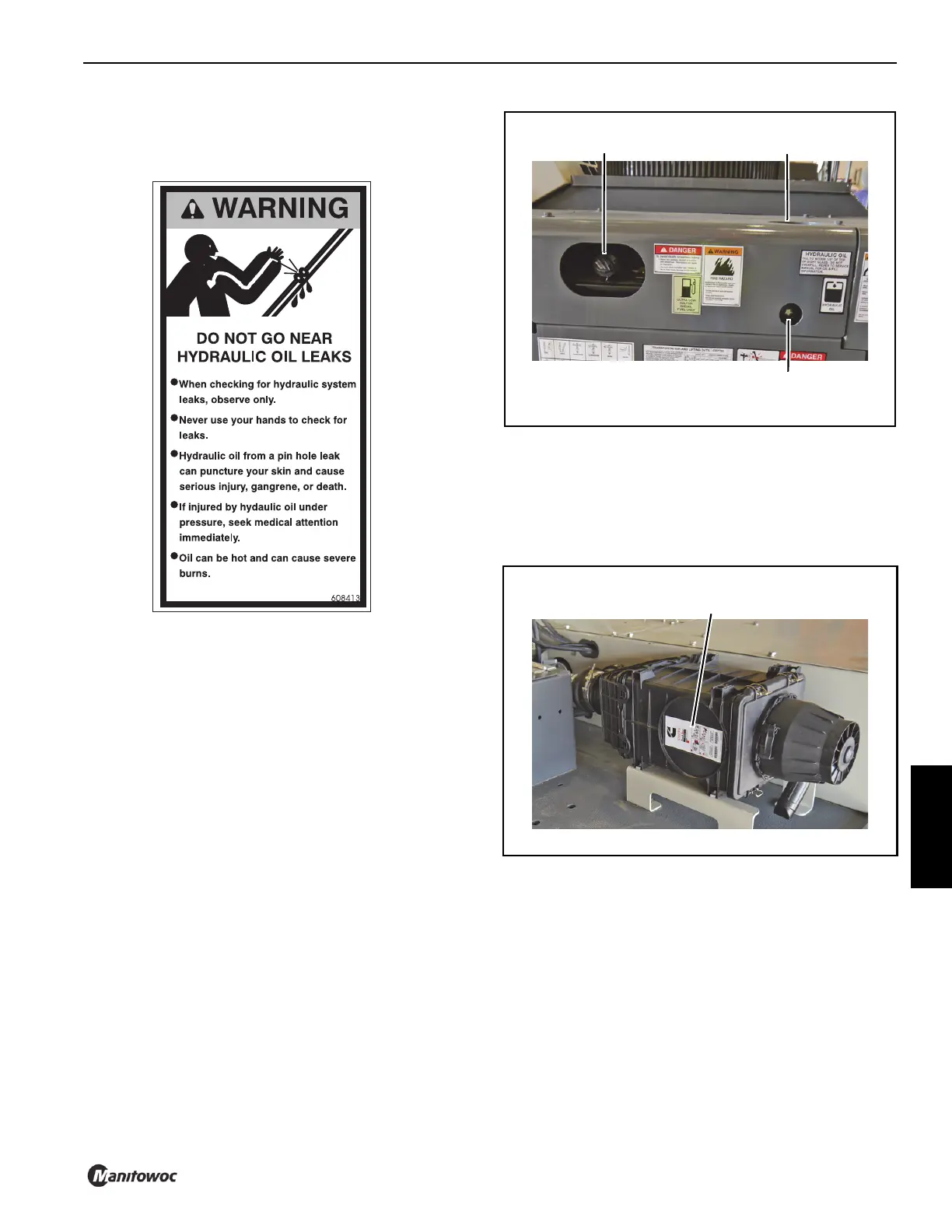

Service the Air Cleaner

Service the engine air cleaner when the following occurs:

• The engine warning light or the engine stop light comes

on in the gauge cluster on the control console.

• The engine ECM transmits the appropriate fault code.

Service the air cleaner according to the instructions on the

air cleaner.

Service the air cleaner only with the engine shut down. Dirt

and debris can enter the engine and cause damage if the

engine is operated with the air cleaner element removed.

Check Tire Pressure

Check the air pressure in the crane’s four tires. Correct

pressure is 125 psi (9 bar).

Also, check for broken studs, rim damage, loose nuts, cracks

and other tire damage.

8938

Hydraulic Oil Sight Gauge

FIGURE 6-11

Hydraulic Oil

Fill Cap

Fuel Fill

Cap

8937

Air Cleaner Service

Instructions

FIGURE 6-12

Loading...

Loading...