Installation and Wiring

3

SECTION 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

*PGM1/PGM2 (Standard Output) = 50mA max.

NOTE: PGM1/PGM2 (Addressable Loop) = 170mA max.

NOTE: To calculate Addressable Loop current, see 2.9 ”AML Device

Wiring’.

**See ‘Combus Current Calculation Chart’ below.

NOTE: For UL, ULC and Commercial Listed applications, the total

standby and alarm current cannot exceed 500mA.

Module Ratings

The current draw of compatible modules is listed below:

Device....................................................... Current Draw (mA)

Keypad (LCD45XX) ............................................................ 50

PC4108A Zone Expander .....................................................30

PC4116 Zone Expander ........................................................30

PC4164 Wireless Receiver ................................................. 110

PC4701 Fire Module............................................................. 35

PC4702BP Dual Bell Output Module................................... 75

PC4204 Relay Output Module.............................................. 30

PC4204CX Combus Repeater ..............................................30

PC4216 Low Current Output Module .................................. 15

ESCORT4580 Audio Assistant........................................... 150

PC4401 Interface Module..................................................... 35

PC4820 Access Control Module .......................................... 35

PC4936 Audio Interface Module.......................................... 65

PC4850 Module .................................................................. 135

Calculating Total Current Requirement

Once you have determined which modules will draw power from

the main panel, use the following chart to calculate the Combus

current.

NOTE: *These units draw current from the Combus to power devices

external to the module. This current must be added to the total Com

-

bus current. See manufacturer's specifications for the current draw of

each device. Each LED assembly draws up to 20mA of current.

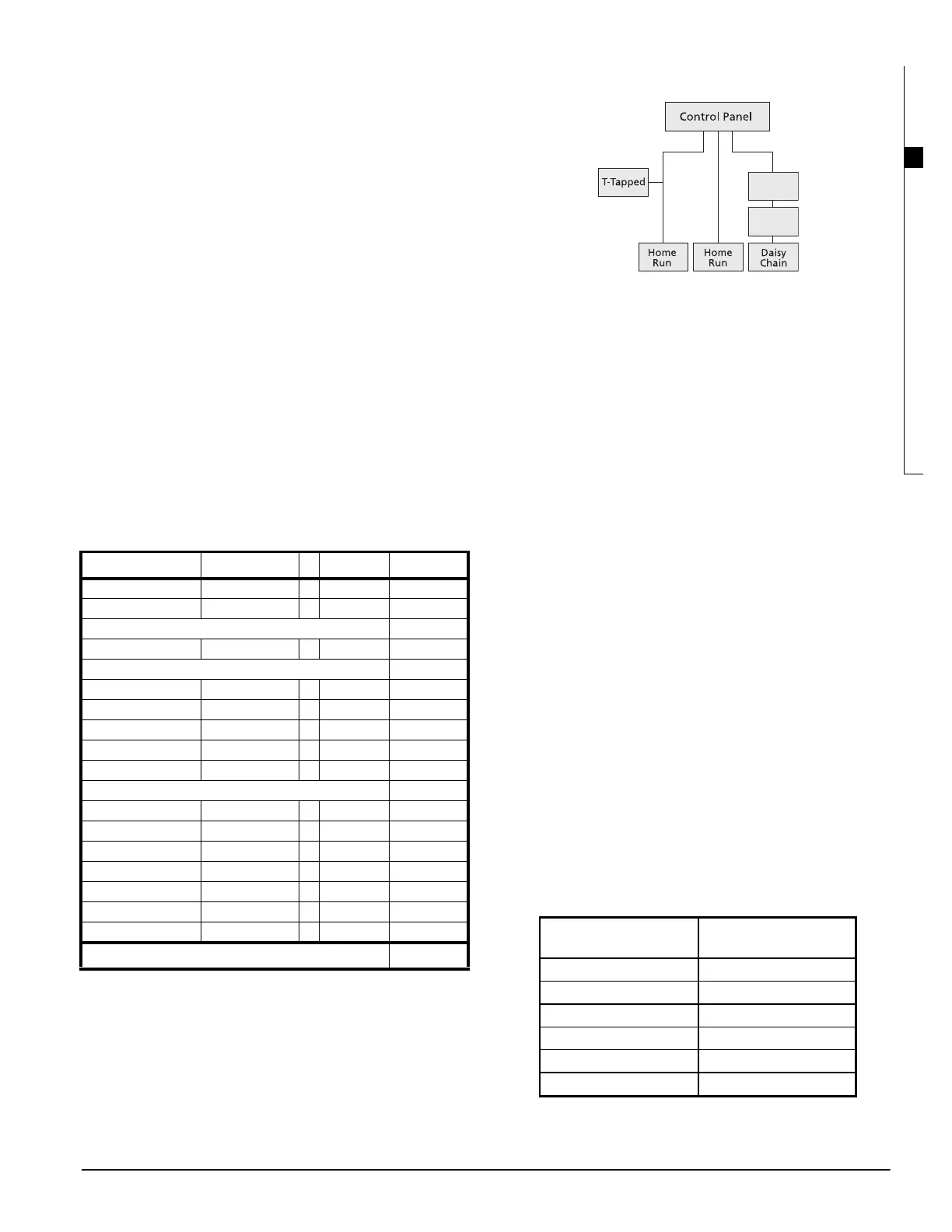

2.5 Combus Operation and Wiring

The Combus is used by the control panel and the modules to com-

municate with each other. The four Combus terminals of the main

panel must be connected to the four Combus terminals or wires of

all modules.

Modules can be home run, connected in a daisy chain or T-tapped

anywhere on the Combus.

The following rules MUST be followed when wiring the Com-

bus:

1. The Combus must be run in minimum 22-gauge wire.

2. No module can be more than 1000' (305m) in cable length from

the main control panel.

3. Shielded wire should only be used in areas that present exces-

sive RF noise or electromagnetic interference. If shielded wire

is used, the maximum distance a module can be located from

the main panel is significantly reduced. Check the capacitance

limit of the wire to calculate the maximum distance (see

’Capacitance Limits’ below).

4. The total capacitance of the Combus wiring must not exceed

80nF (see ’Capacitance Limits’ below).

5. Do not run Combus wire runs in parallel with AML wire runs.

Maintain minimum 2” separation between the cables.

Line Loss

When current is drawn through a piece of wire, voltage will be

lost due to the wire’s resistance. This voltage loss must be consid

-

ered for all installations.

To ensure proper operation, at least 12.5VDC must be applied to

all modules on the system (when AC is applied and the battery is

fully charged). If less than 12.5V

DC is applied, system operation

will be adversely affected.

To correct the problem, try any or all of the following:

1. Connect a PC4204/PC4204CX power supply near the module

to provide power to the Combus.

2. Reduce the length of the Combus run to the module.

3. Increase the gauge of wire.

Capacitance Limits

An increase in capacitance on the Combus will affect data trans-

mission and will cause the system to slow down. Capacitance will

increase for every foot of wire added to the Combus. The capaci

-

tance rating of the wire used will determine the maximum length

of the Combus.

For example, 22-gauge, non-shielded, 4-conductor wire has a typ-

ical capacitance rating of 20 picofarads per foot (which is 20nF/

1000’). For every 1000' of wire added – regardless of where it is

run – the capacitance of the Combus will increase by 20nF.

The following chart indicates the total Combus wire allowed

depending on the capacitance rating of the wire used:

Wires run in parallel also increase Combus capacitance. For

example, when using 20nF wire, the following would be some of

the combinations allowed:

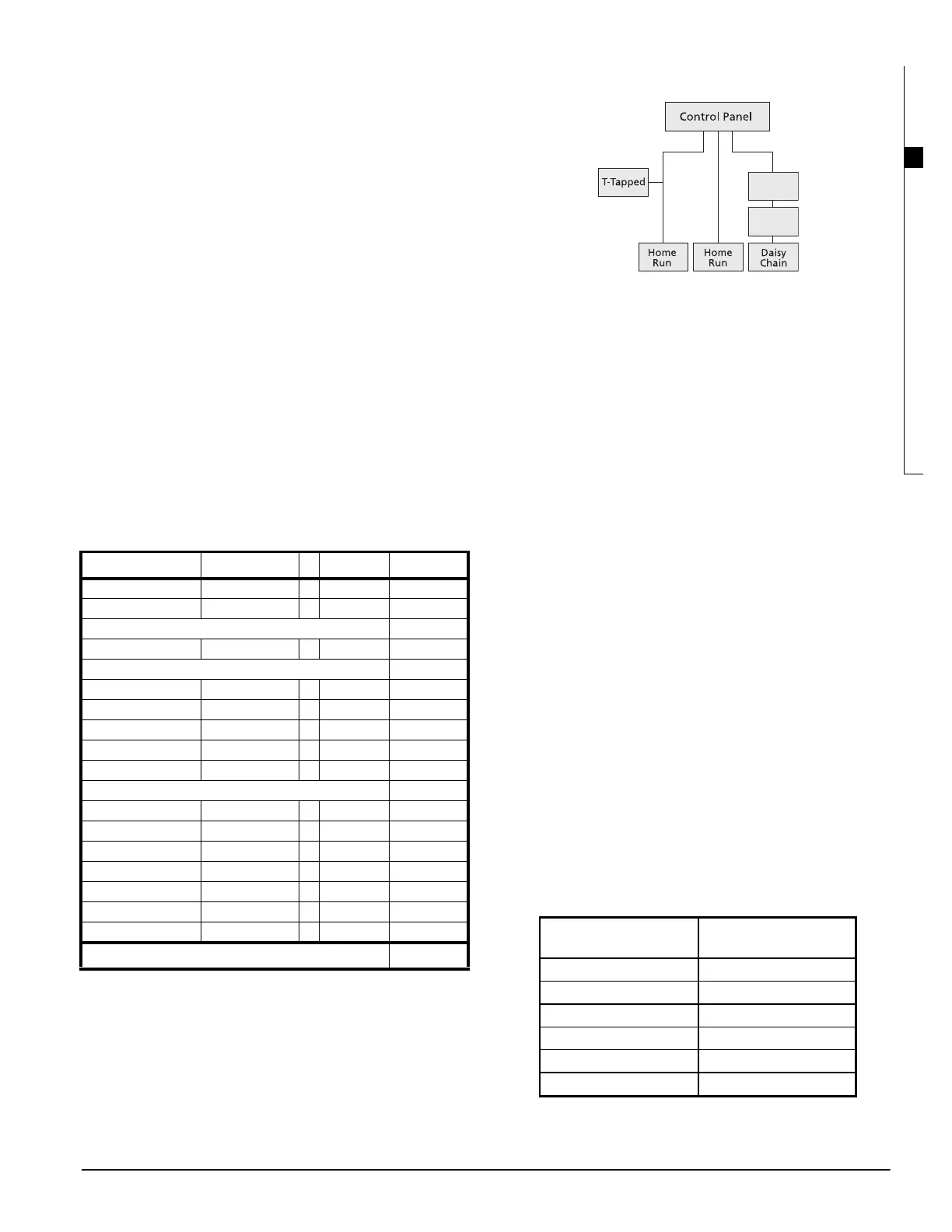

Combus Current Selection Chart

Item Current (mA) x Quantity Total (mA)

Keypad 50 x

PC4108A* 30 x

Current required for connected devices =

PC4116* 30 x

Current required for connected devices =

PC4164 110 x

PC4701 35

PC4702BP 75 x

PC4204/PC4204CX 30 x

PC4216* 15 x

Current required for connected devices =

ESCORT4580 150

PC4401 35 x

PC4820 35 x

PC4850 135 x

PC4936* 65

T-Link 150

Skyroute 30

Total Combus Current =

Wire Capacitance per

1000'(300m)

TOTAL Combus W ire

Len gt h

15nF 5300'/1616m

20nF 4000'/1220m

25nF 3200'/976m

30nF 2666'/810m

35nF 2280'/693m

40nF 2000'/608m

Loading...

Loading...