McHale Fusion 3 Baler & Wrapper

78

The McHale Fusion 3 is a fixed chamber baler with the bale diameter usually

1230 mm - 1270 mm. However, bales in excess of 1270 mm, can be

produced if any of the following conditions exist:

(a) If not enough net has been applied to the bale (especially in high dry

matter material)

(b) Excessive feeding of the bale chamber, not allowing the bale to be

properly compacted to its correct size.

8.3 Wrapping process

The wrapping process starts automatically as soon as the bale has been transferred

from the bale chamber to the wrapping table (chamber door closed, rear roller in fully

raised position and the access door closed). After the bale is wrapped with the selected

number of film layers, two (2) cut & hold units grip and cut the film. The wrapping cycle

is completed and the bale is ready for discharging.

If “Auto Tip” is selected, the wrapped bale is discharged when netting of the next bale

starts.

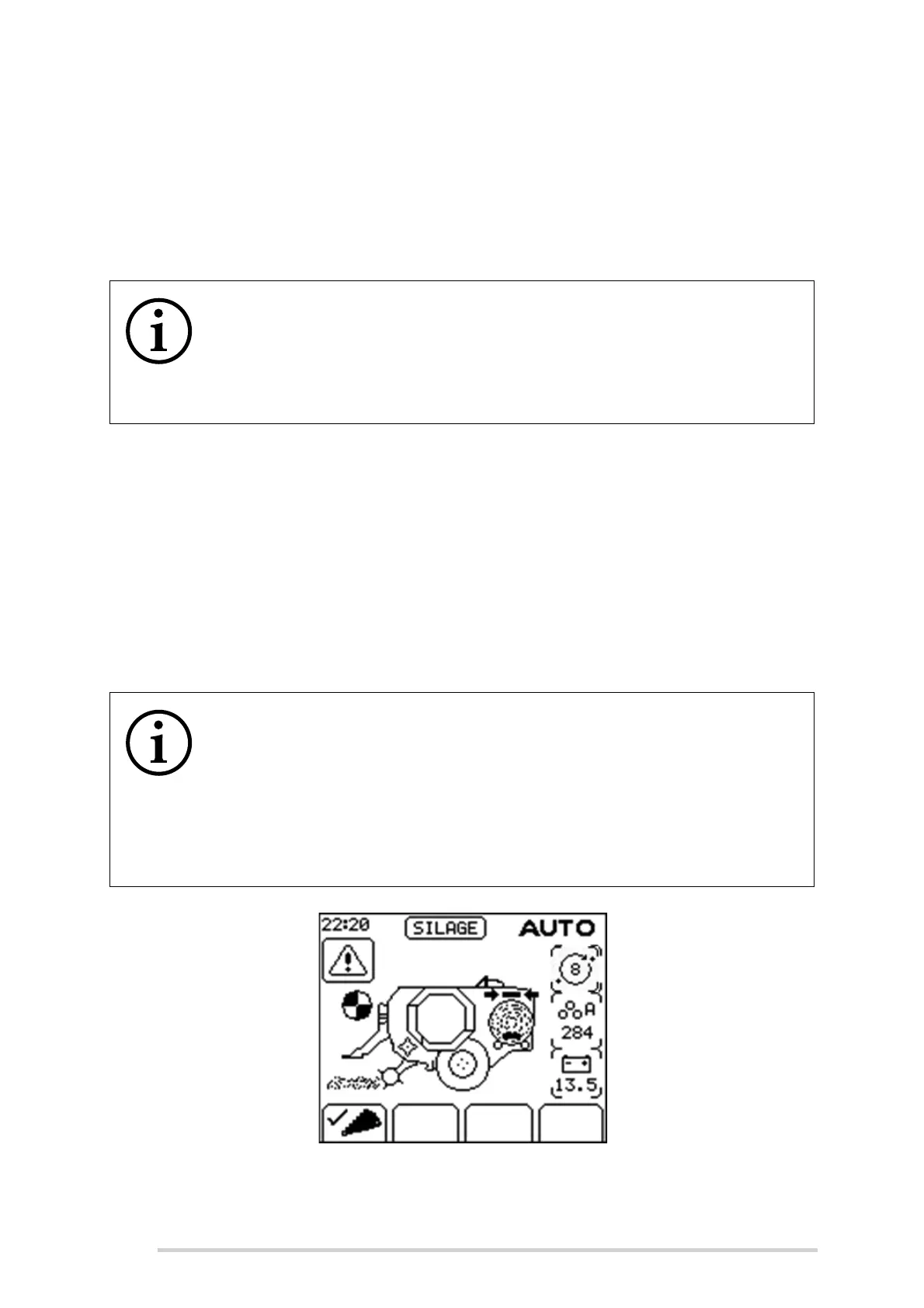

Figure 8.i - Dispenser position error symbol

NOTE: Check bale diameter for enough wrapping ring rotations

It is very important to note that bales in excess of 1300 mm will not have

enough “wrapping ring rotations” if the above exercise has been carried

out on a normal 1250 mm bale. Therefore, it is important to check the

bale diameter at every change in crop condition or in differing crop row

widths and densities.

NOTE: Bale will not transfer if dispenser ring is in wrong position

The bale will not transfer from the baler chamber if the dispenser ring is

in the wrong position. This is a safety feature and is normal. In this case

and audible alarm will sound and the “Dispenser Position” error symbol

will be displayed in the control box display. The forward and reverse soft

key indicators will become active on the control box. Press the

appropriate button in order to correct and once corrected the bale will

transfer and the wrapping cycle will begin.

Loading...

Loading...