McHale Fusion 3 Baler & Wrapper

77

8.2 Plastic film requirements

Good quality silage depends on the use of top quality plastic film, in addition to well

shaped dense bales. Low standard film material will not produce good silage

regardless of how well the machine wraps the bale. The plastic film should be used and

stored according to the instructions of the film manufacturer.

It is recommended that a minimum of four (4) layers of film be applied to the bale. If the

material being wrapped is of a hard of stemmy nature it may be necessary to apply six

(6) or eight (8) layers to ensure a good airtight package.

8.2.1 Determining the number of wrapping ring rotations

To determine the number of wrapping ring rotations required to cover a bale, carry out

the following procedure:

1. Using manual operation, from the control box, manually count the number of

wrapping ring rotations to cover the bale completely with plastic film

2. Add 0.5 to this number

3. Multiply the resultant figure by 2 (for 4 film layers), 3 (for 6 film layers), 4 (for 8

layers), 5 (for 10 layers), etc.

4. Round up to the next full number if the result contains a fraction of a full

number.

Example:

Number of “Wrapping ring rotations” to cover bale: 3.5 = (x)

Number of rotations to apply 4 layers of film to bale = (3.5 + 0.5) x 2 = 8

Important Notes:

(x) “Wrapping ring rotation” = both dispensers rotating 360° around the bale.

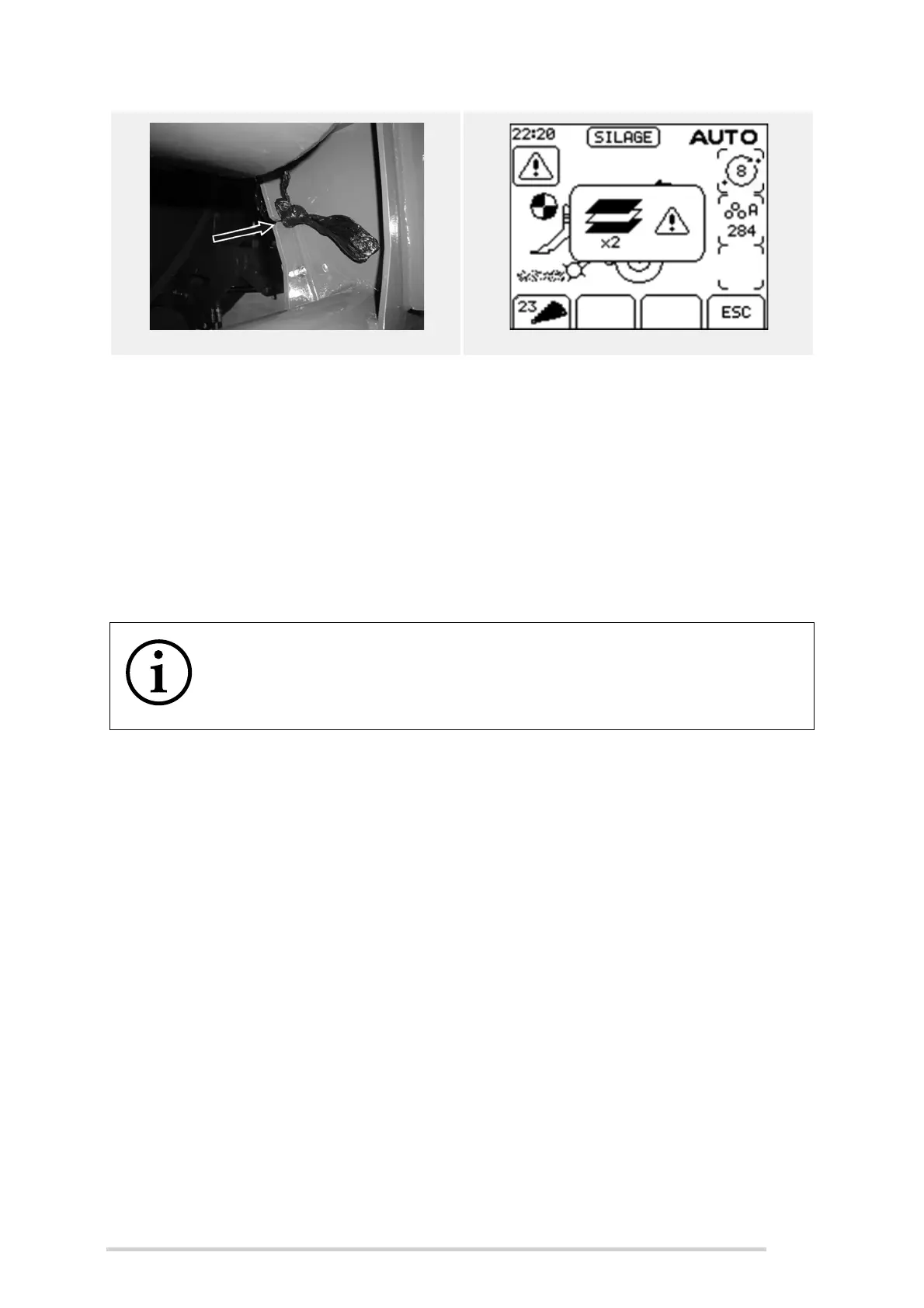

Figure 8.g - R.H.S Film slot Figure 8.h - “Out of film”

NOTE: Operator must check to ensure bales are wrapped correctly

The operator needs to ensure that the bale is wrapped correctly. It is

good practice to check the bales regularly after being wrapped for torn,

split or perforated plastic film.

Loading...

Loading...