Chapter 3 – Initial Commissioning

18

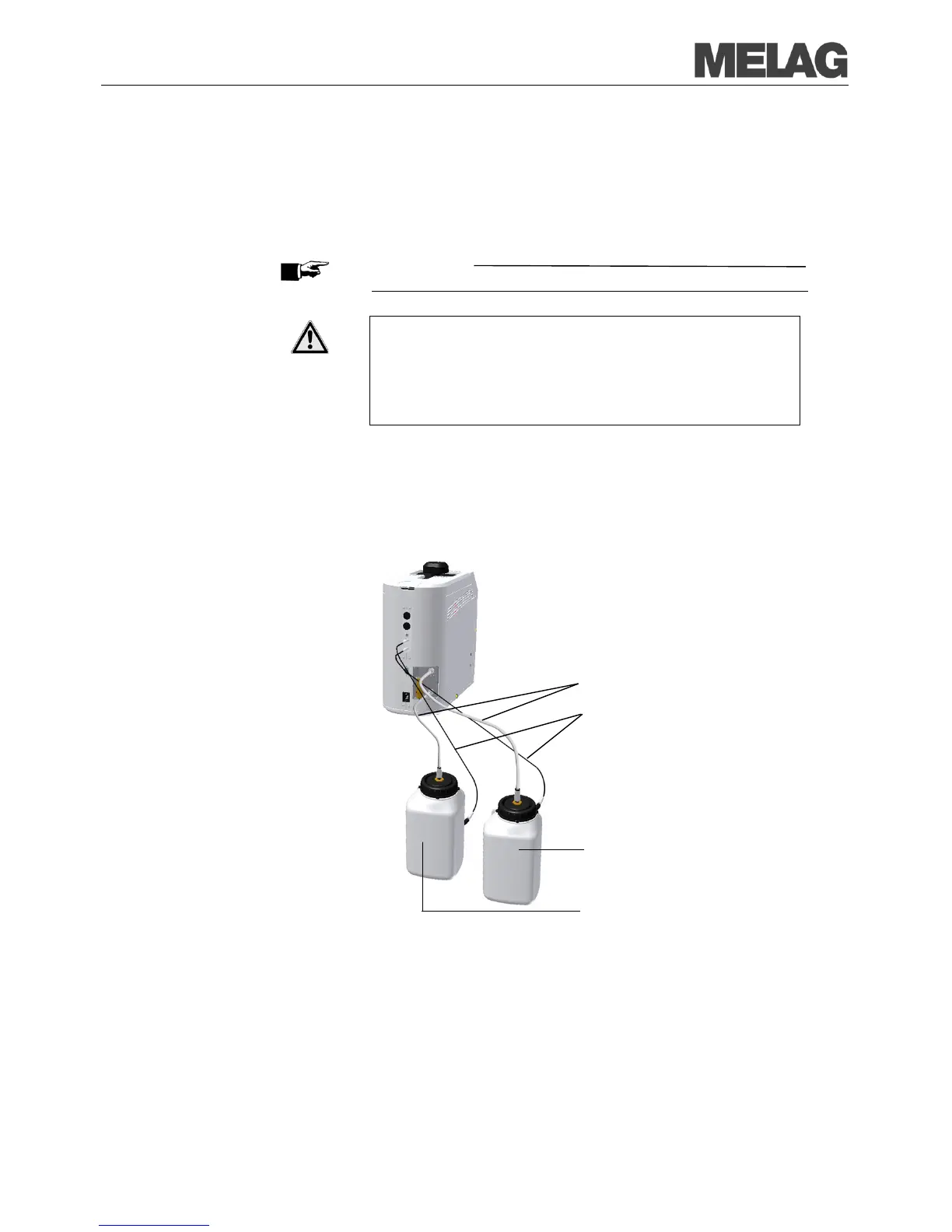

container, the cable is connected on the rear side of the steam sterilizer

(

If the connection for feed and waste water enquiry were mixed up by

mistake, the information on the display for container filling and/or emptying

will be incorrectly displayed.

-water hose must be laid dip-free with continuous descent.

■ It is absolutely necessary to insert both hoses to the end into the

couplings.

In case of non-observance there is danger of burns, as hot steam

may escape on the rear side and/or air may enter the lines when

sucking feed water and impact the functionality of the steam

sterilizer.

After the connection fill in tap water (approx. 10 cm high) into the waste

water container in order to cool the condensate coil and add commercially

available

instrument disinfectant to prevent germ formation in the waste

Use half of the amount recommended by the

manufacturer in order to preserve the material of the condensate coil.

This is required during initial commissioning and after every emptying of

the waste water container.

Connection hoses

Cables for water level monitoring

Waste water container

Feed water container

All MELAG water treatment units comply with the following requirements:

The water pressure at the output of the water treatment unit amounts

to min. 0.5 and max. 10 bar.

The temperature of the feed water reaches max. 40 °C.

At 0.5 bar, the flow rate reaches min. 0.8 l/min for a short time and

then an average of 0.025 l/min (= 1.5 l/h).

Connection to a water

treatment unit

If the steam sterilizer should receive feed water fully automatically from a

water treatment unit, the

steam sterilizer is connected using a

PTFE hose

with exterior diameter Ø 6 mm to

the water treatment unit. It is also

in parallel to a different unit, using

a T

-piece, to an already existing water treatment unit of sufficient

Loading...

Loading...