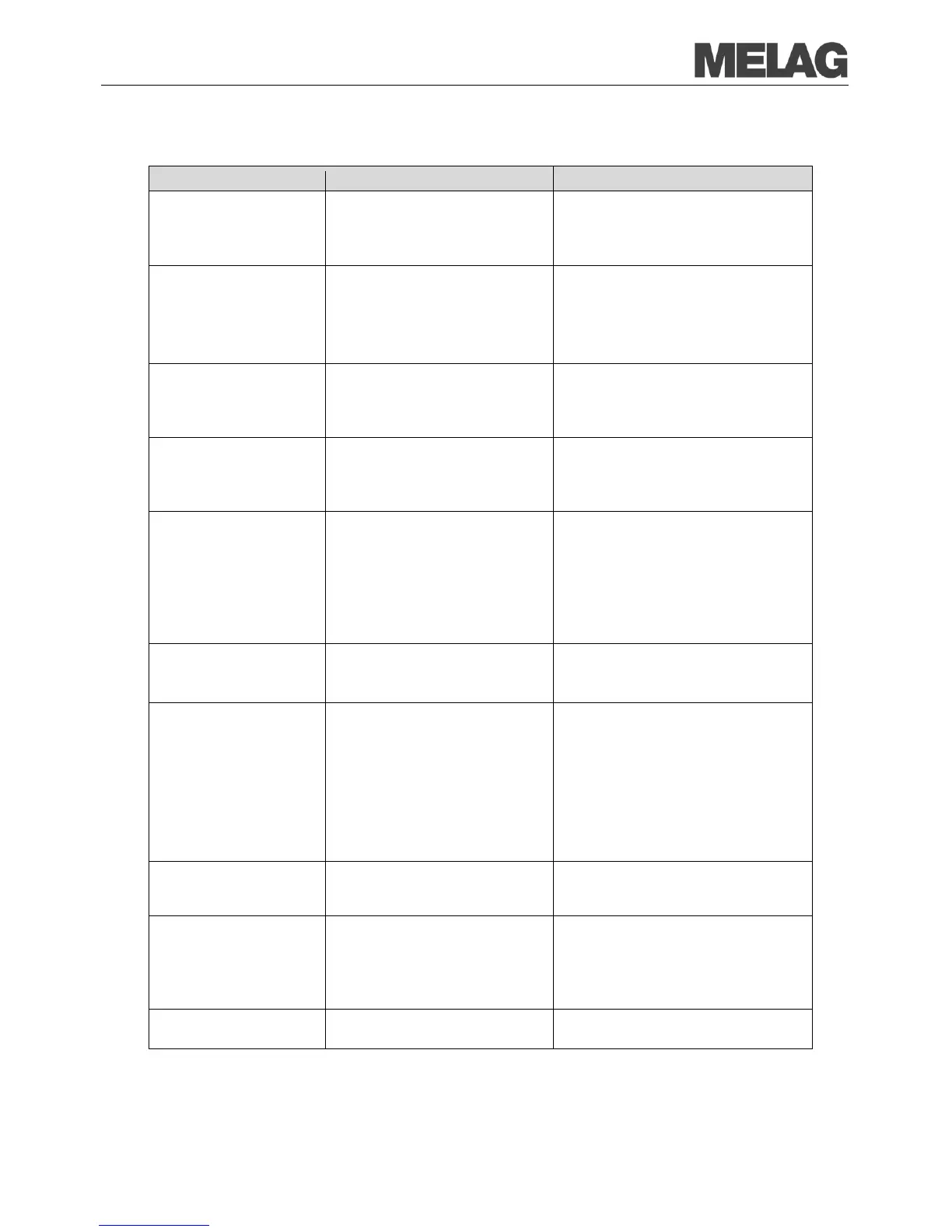

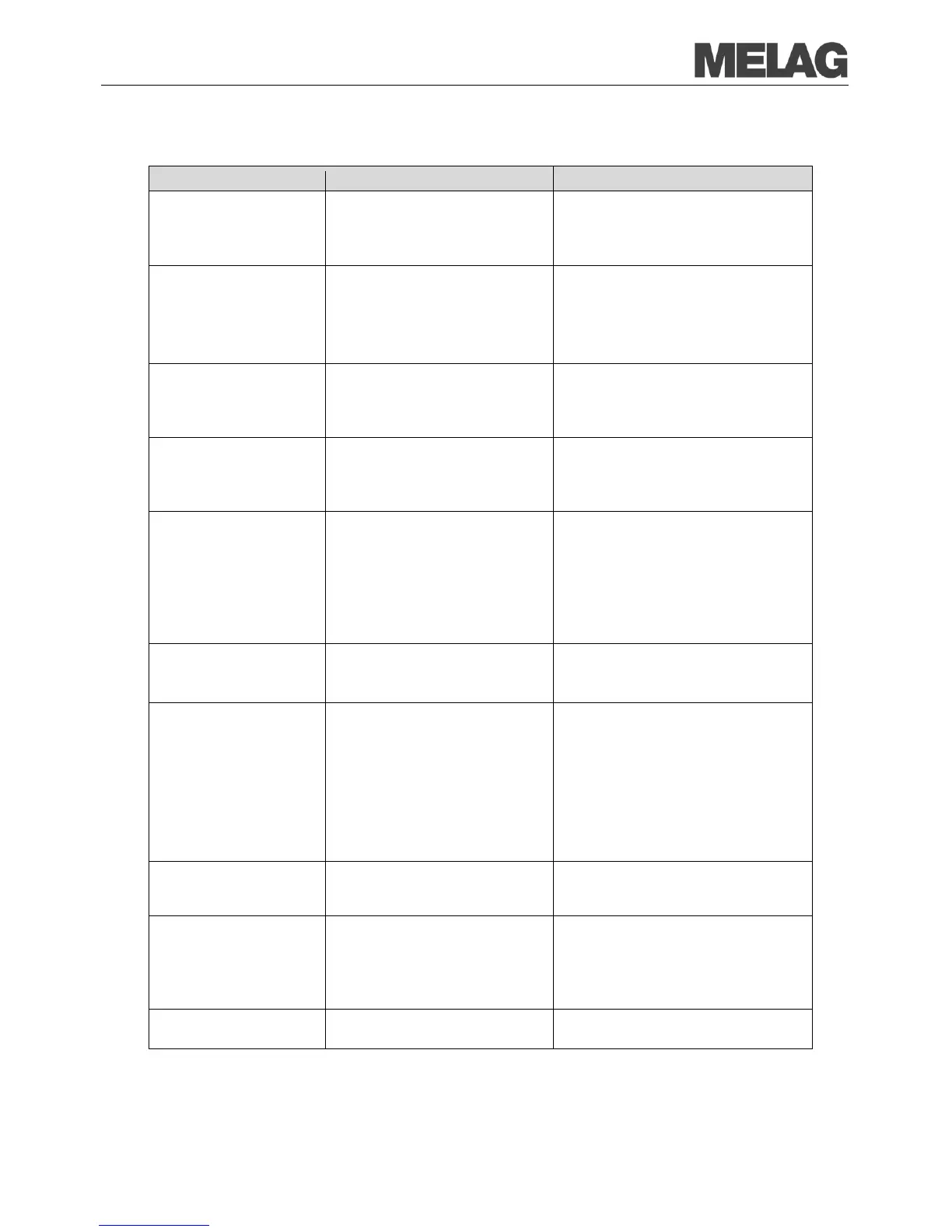

Chapter 9 – Malfunctions

54

On repeated occurrence select option

Automatic pre-heating No ( see

page

28, Select automatic pre-heating)

and inform your specialist dealers

Monitoring time for the pressure

release in the outflow procedure

during fractionations was exceeded

Sieve tray contaminated or dented

Waste water hose kinked

Clean sieve bottom and check waste water

hose (see page 44).

Check installation of the waste water hose.

Upon repeated occurrence, inform your

specialist dealer.

The maximum admissible deviation

of the computer-internal signal

conditioning (A/D converting) was

exceeded

Upon repeated occurrence, inform your

The maximum admissible deviation

between the two temperature

sensors for the steam temperature

was exceeded

Upon repeated occurrence, inform your

loss/Sterilize sterile filter

The loss of the operating voltage

occurred after the start of a program

The malfunction message occurs after the

operating voltage is again available.

Check building-side installation. If no

defects are detectable, notify MELAG

Disconnection of the steam sterilizer

Only terminate a running program with K

The maximum switch-on time of the

steam generator for achieving the

control pressure was exceeded

Upon repeated occurrence, inform your

Fault 34: Sterilization TU1

Shortfall of minimum permissible

sterilization temperature (temperature

Operate steam sterilizer with smaller load.

Check door gasket for wear or damage,

exchange as needed (see page 44).

Upon repeated occurrence, inform your

specialist dealer.

Clean sieve bottom and check waste water

hose (see page 44).

Fault 35: Sterilization TO1

Exceeding the maximum permissible

sterilization temperare (temperare

Upon repeated occurrence, inform your

Fault 36: Sterilization PU

Shortfall of the minimum sterilization

Operate device with smaller load

Check door gasket for wear or damage,

exchange as needed (see page 44).

Upon repeated occurrence, inform your

Fault 37: Sterilization PO

Exceeding the maximum permissible

sterilization pressure

Upon repeated occurrence, inform your

specialist dealer.

Loading...

Loading...