90-830234R3 DECEMBER 1997 POWERHEAD - 4-35

Powerhead Disassembly

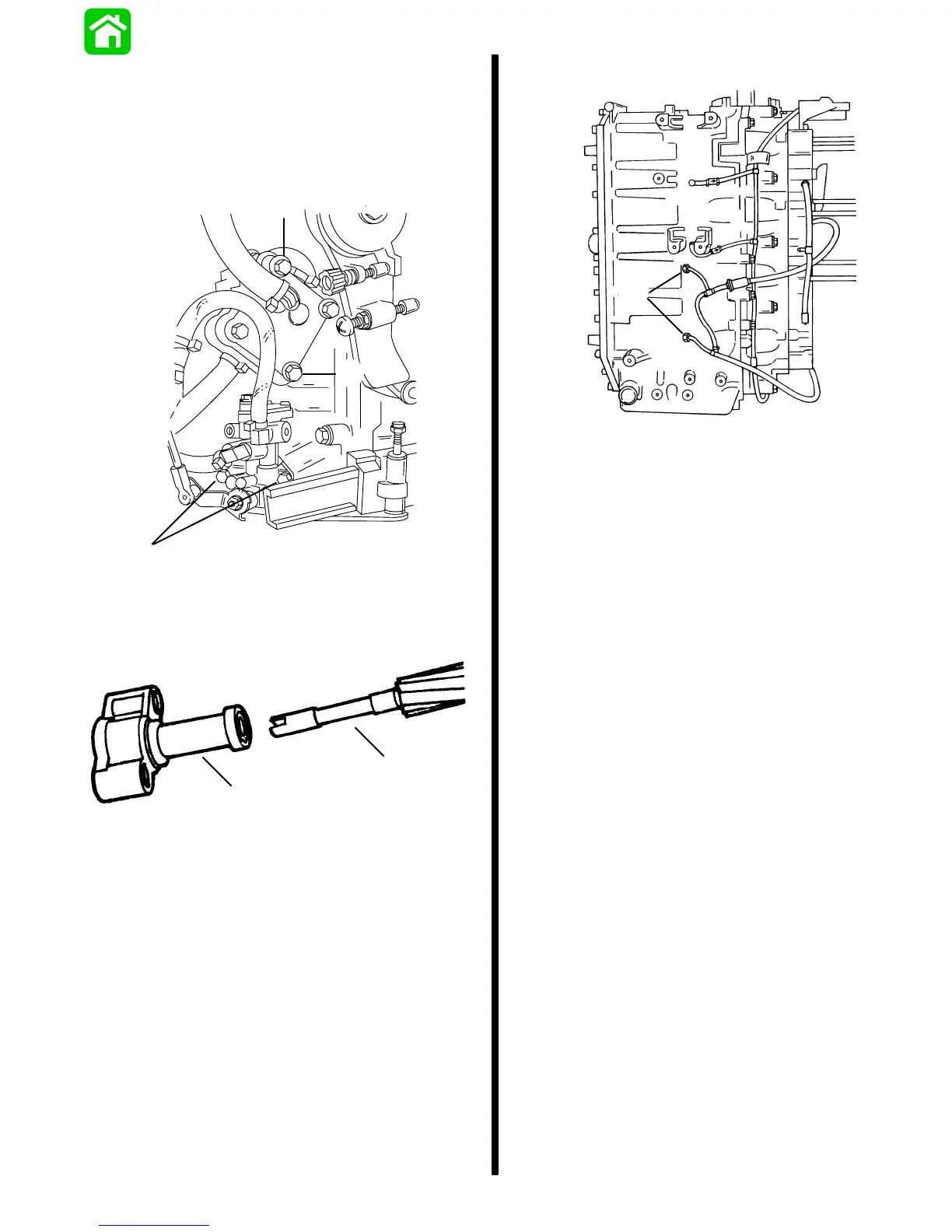

• Remove fuel pump by removing 2 screws.

• Remove oil injection pump by removing 2 bolts.

• Remove hoses to fuel pump and oil injection

pump.

a

a

b

53992

a - Bolts – Fuel Pump

b - Bolts – Oil Pump

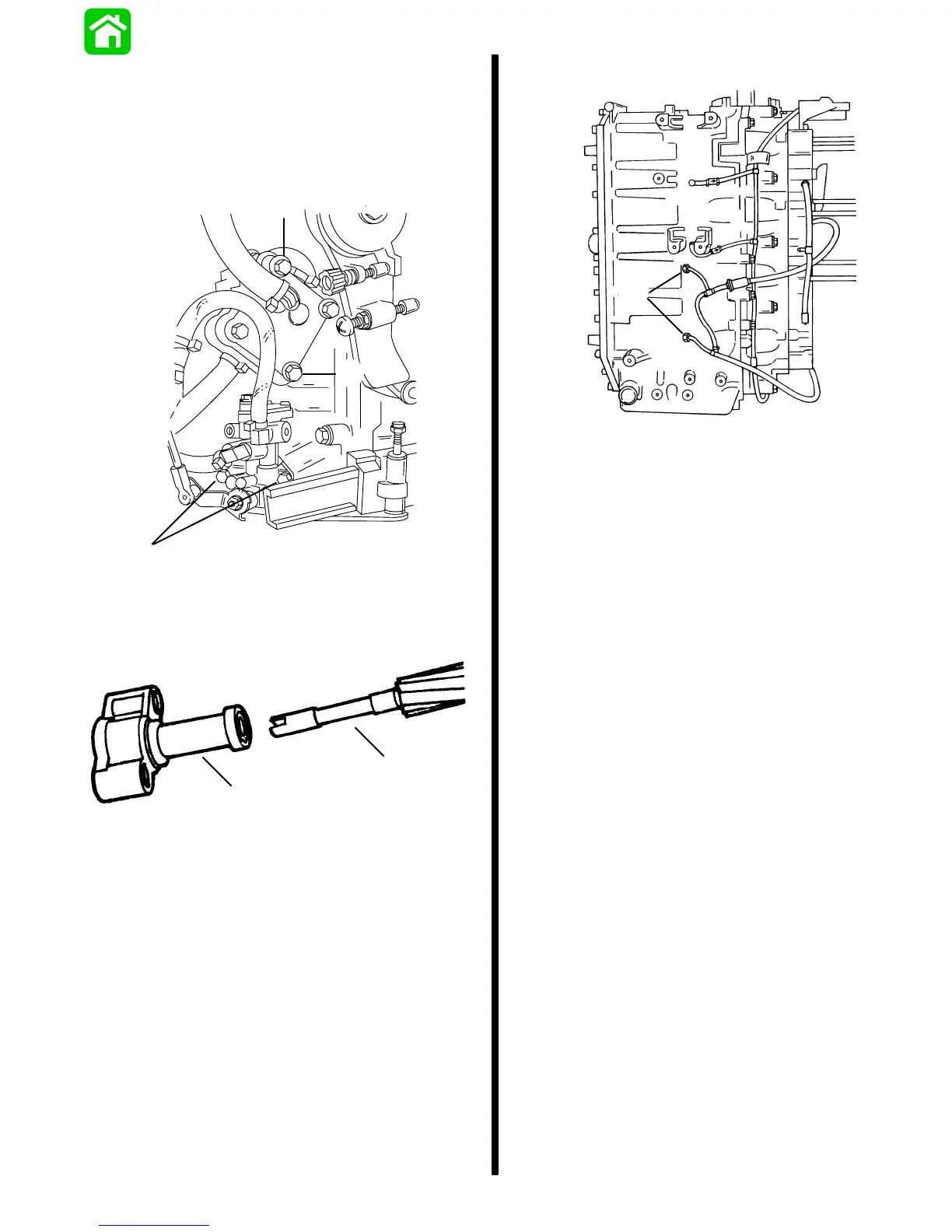

• Remove oil injection pump shaft and housing.

b

a

20041

a - Pump Housing

b - Pump Shaft

• 4 Cylinder Models Only – Remove accelerator

pump hoses from #3 and #4 cylinder check valve

fittings.

• Remove check valves.

a

52478

a - Check Valve (4 Cylinder Models Only)

• Accelerator check valves can be tested for prop-

er performance as follows:

1. Spray a small amount of WD-40 into barbed end

of check valve.

2. Blow out excess WD-40 with high pressure air.

3. Apply suction to barbed end with small air vacu-

um hand pump.

4. Apply suction until valve opens (22-28 inches of

vacuum).

5. Within 30 seconds after stopping suction, vacu-

um should not fall below 5.0 hg.

NOTE: Accelerator check valves should not be

installed in block while honing operations are being

performed nor reinstalled until all block cleaning pro-

cedures have been completed.

Loading...

Loading...