90-830234R3 DECEMBER 1997 POWERHEAD - 4-43

• Check tightness of piston ring locating pins. Lo-

cating pins must be tight.

• Thoroughly clean pistons. Carefully remove car-

bon deposits, with a soft wire brush or carbon re-

mover solution. DO NOT burr or round off ma-

chined edges.

• Inspect piston grooves for wear and carbon accu-

mulation. If necessary, scrape carbon from piston

ring grooves being careful not to scratch sides of

grooves. Refer to procedure for cleaning piston

ring grooves.

CLEANING PISTON RING GROOVES

IMPORTANT: The piston rings are half-keystone

rings – (tapered on the top side) - follow cleaning

and inspection carefully! Chromed ring is

installed on top.

a

a - Enlarged View of Piston Ring Grooves

Care must be taken not to scratch the side sur-

faces of ring groove. Scratching the side sur-

faces of the ring groove will cause damage to the

ring groove.

• Use a bristle brush and carbon remover solution

to remove carbon from side surfaces.

• A tool can be made for cleaning the inner diame-

ter of the tapered ring grooves. The tool can be

made from a broken tapered piston ring with the

side taper removed to enable inside edge of the

ring to reach the inside diameter of the groove.

Carefully scrape the carbon from inner diameter

of ring grooves. Care must be taken not to dam-

age the grooves by scratching the surfaces of the

grooves.

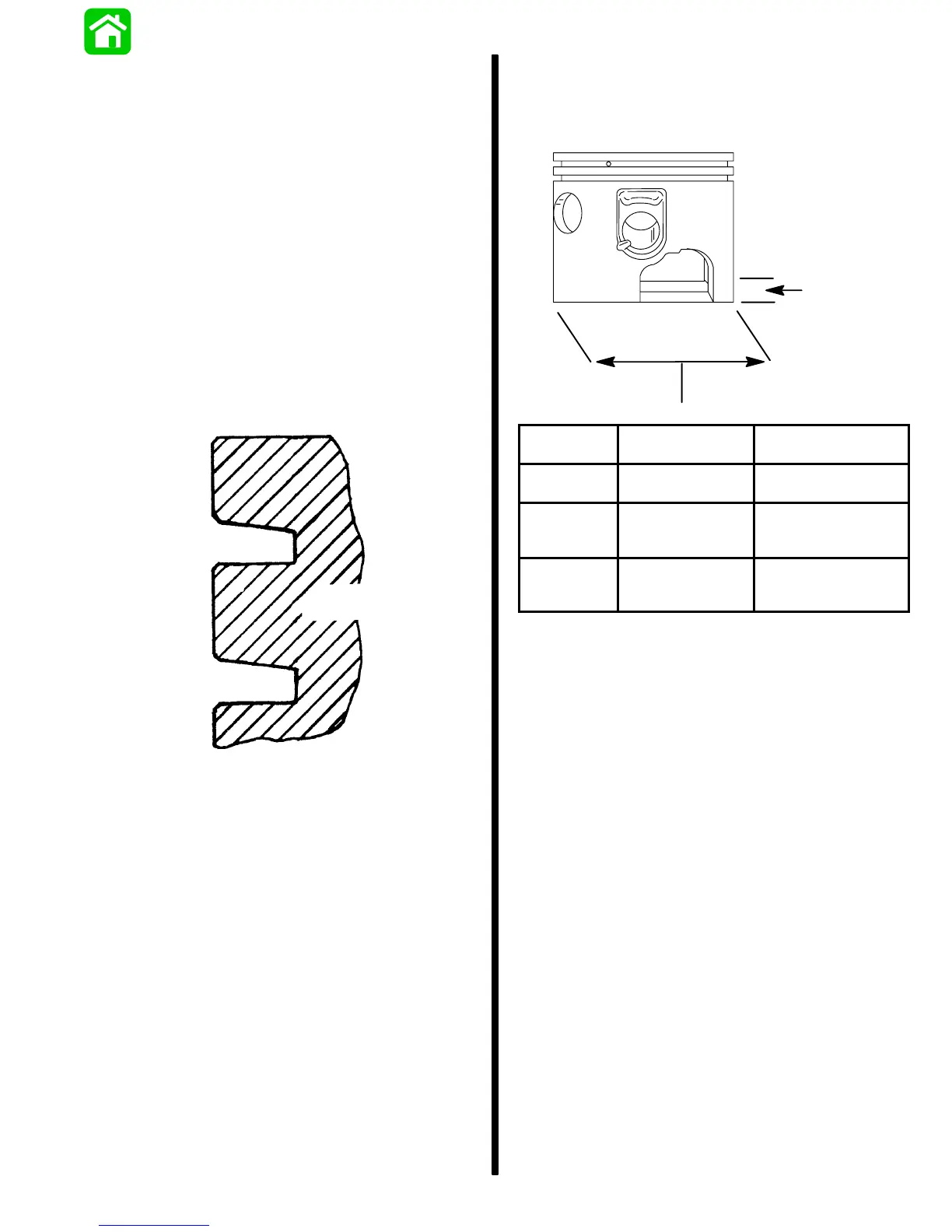

MEASURING PISTON SKIRT

Measure piston skirt at right angle (90) to piston pin

centerline, 0.50 in. (12.7mm) up from bottom edge of

skirt.

53987

0.50 in.

(12.7 mm)

PISTON

SIZE

PISTON SKIRT DI-

AMETER

CYLINDER BORE

FINISH HONE

Standard

Piston

3.495 in.

(85.62mm)

3.501 in.

(88.77mm)

0.015 in.

(0.38mm)

Oversize

3.510 in.

(86.00mm)

3.516 in.

(89.15mm)

0.030 in.

(0.75mm)

Oversize

3.525 in.

(86.39mm)

3.531 in.

(89.52mm)

Loading...

Loading...