6A-28 - LOWER UNIT 90-830234R3 DECEMBER 1997

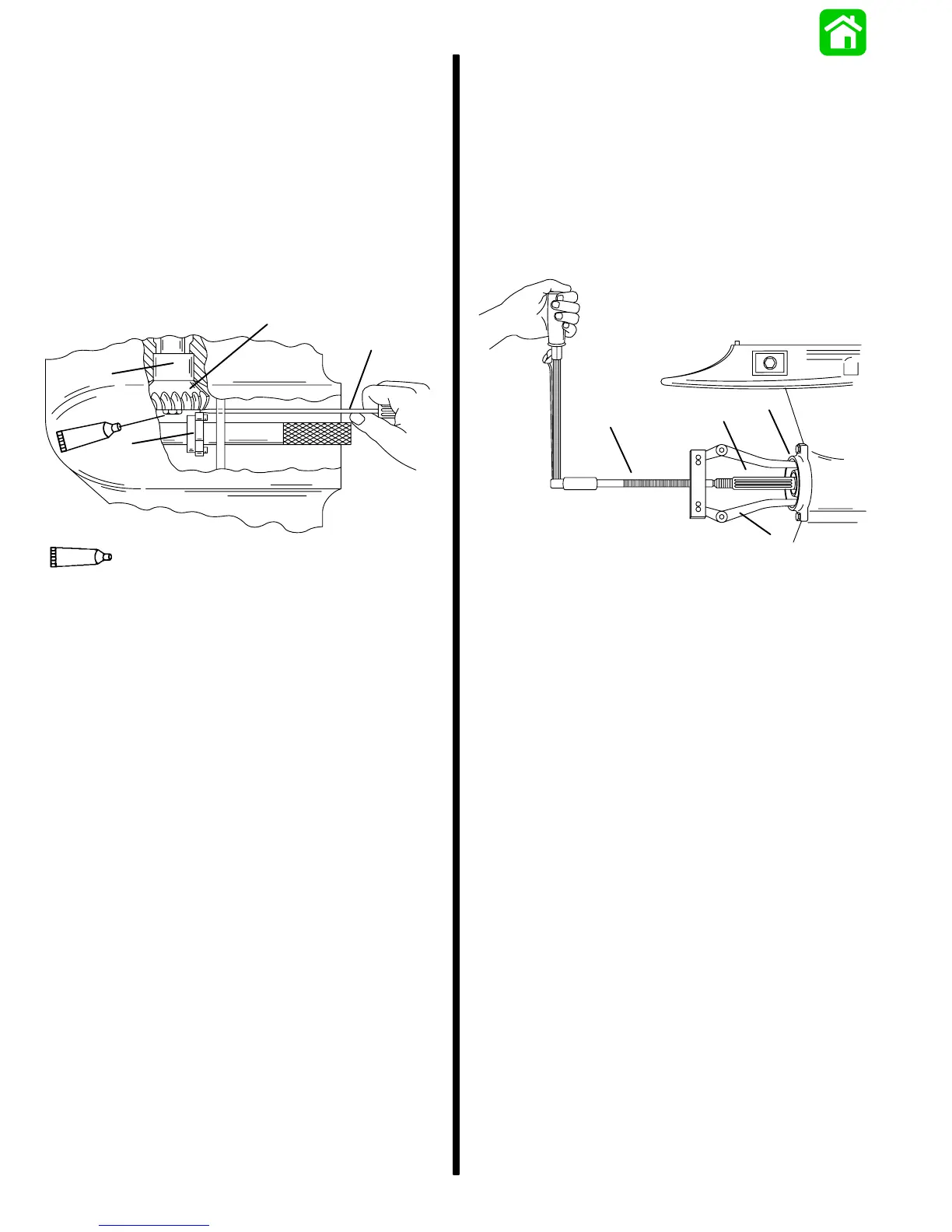

12. Determine pinion gear depth by inserting a feeler

gauge thru access hole in locating disc.

13. The correct clearance between gauging block

and pinion gear is 0.025 in. (0.64mm).

14. If clearance is correct, leave Bearing Preload

Tool on drive shaft and proceed to “Determining

Forward Gear Backlash,” following.

15. If clearance is incorrect, add (or subtract) shims

from above bearing race to lower (or raise) pinion

gear. When reinstalling pinion nut, apply Loctite

271 on threads of nut.

a

c

d

b

24643

7

Loctite 271 (92-809820)

7

a - Feeler Gauge

b - Gauging Block

c - Pinion Gear

d - Bearing Race

DETERMINING FORWARD GEAR BACKLASH

NOTE: Read entire procedure before attempting any

change in shim thickness.

1. Obtain correct pinion gear depth; refer to “Deter-

mining Pinion Gear Depth,” preceding.

2. Install Bearing Preload Tool (91-14311A2) on

drive shaft; refer to “Determining Pinion Gear

Depth,” preceding.

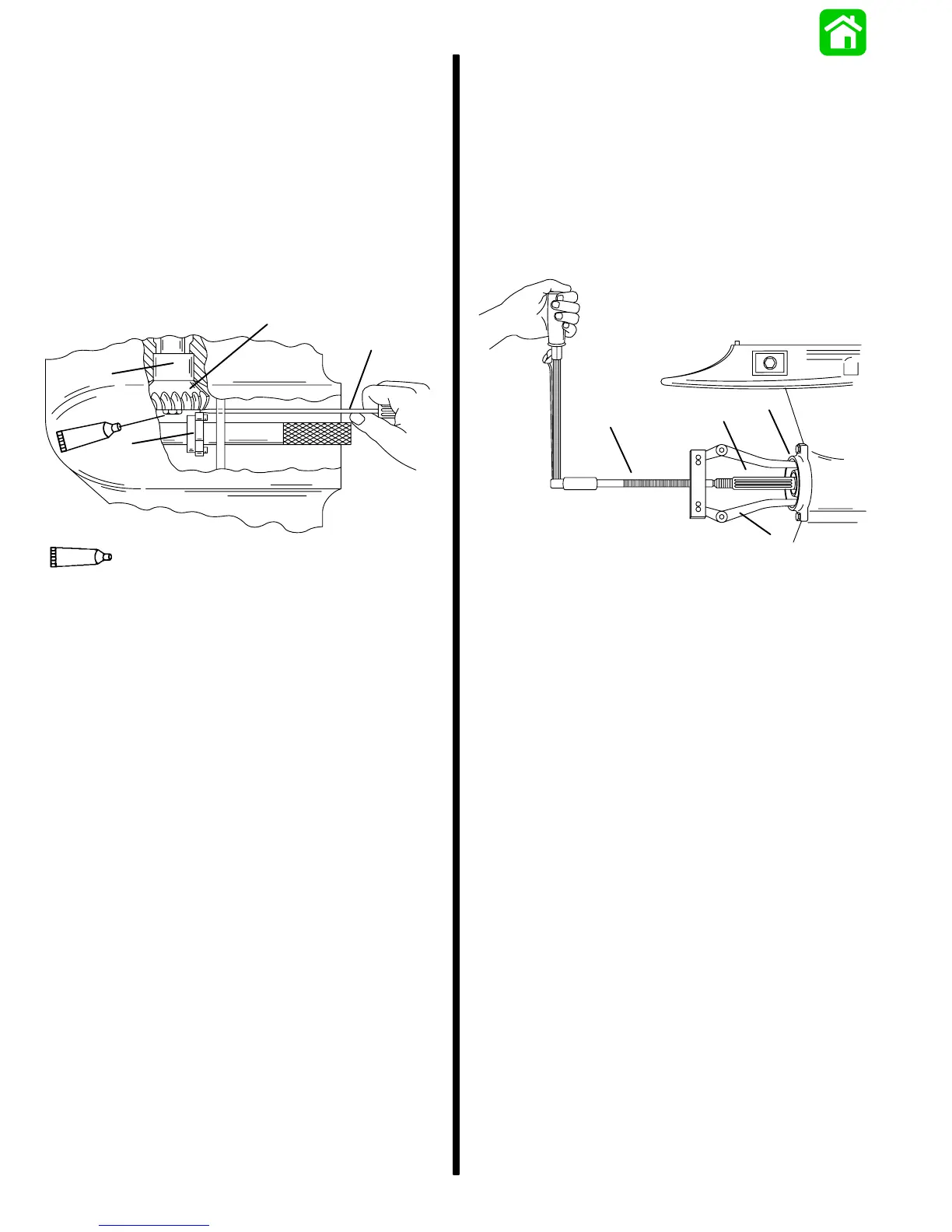

3. Install components as shown.

d

a

b

c

53936

a - Propeller Shaft*

b - Bearing Carrier* (Assembled)

c - Puller Jaws (91-46086A1)

d - Puller Bolt (91-85716); Torque to 45 lbs. in. (5.1 N·m)

* Refer to “Bearing Carrier and Propeller Shaft Installation,”

following.

4. Rotate drive shaft 5 to 10 revolutions. This should

properly seat forward gear tapered roller bearing.

Loading...

Loading...