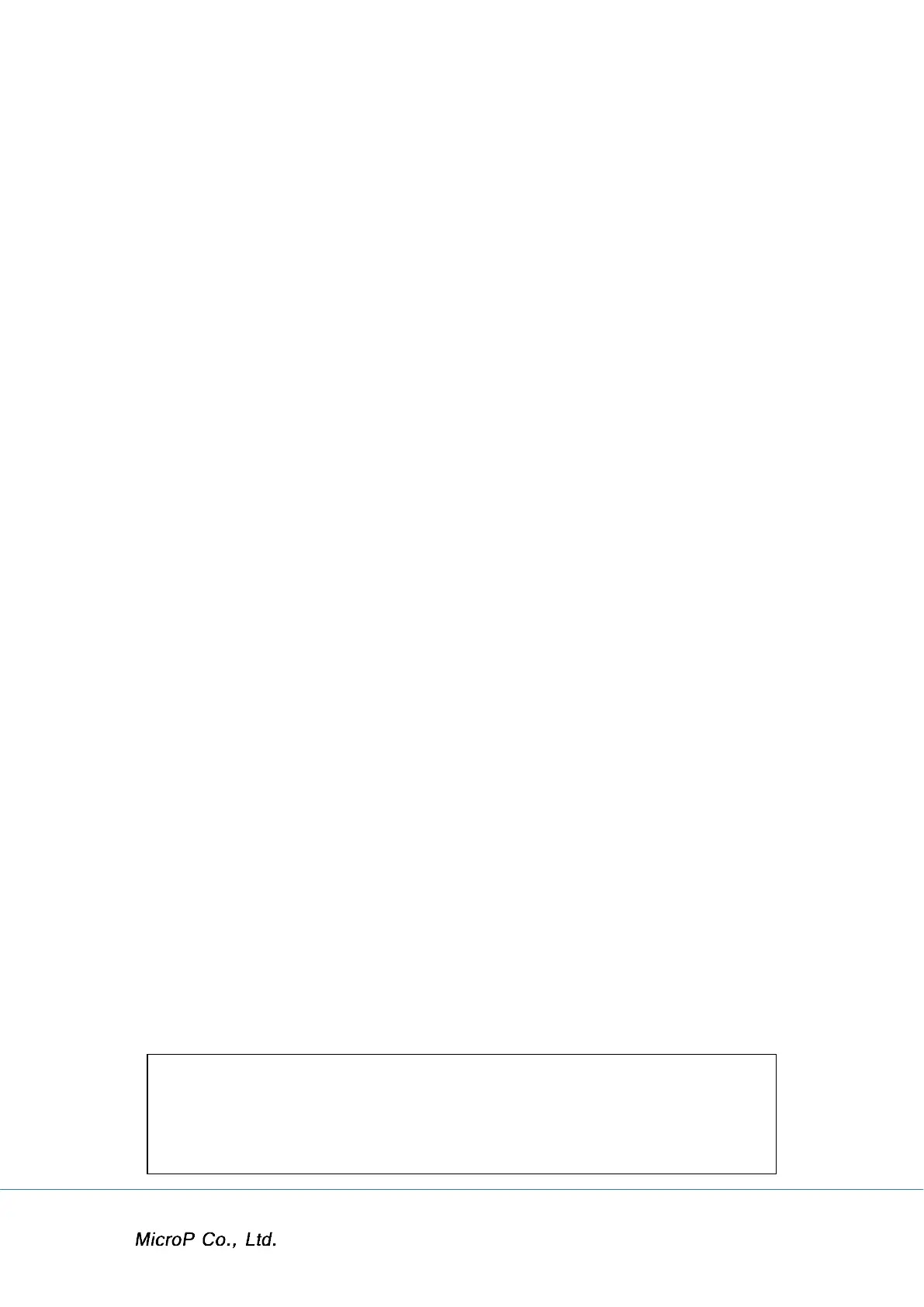

XRF-2000 Series Operating Manual

70

A further aid is to define the problem nature by the following criteria:

1. Is the problem always the same?

2. Does the problem appear at regular intervals or random intervals?

The correct answers to many of the questions suggested above may not be an

easy task, although the solution to many may be very simple.

The XRF-2000 constantly monitor the major signals and component operations

in the system. Many problems, usually hardware and operation-related are

No System Response

When the system has no response massage,

1. The USB communication cable on the computer side is not connected

or the connector is bad.

2. Turn off the system and turn it on after 5 second.

3. Check Power on Lamp on the main switch. If power on lamp is not

illuminate, check the main fuse on rear side of system.

Peaks Not in the Correct Position

The proper way to verify energy calibration is to perform system adjustment as

described in Chapter 4.16. Common reasons for peak shifts are:

- Cabinet heat-up due to dust in the filter or faulty fans.

- Big environment temperature change

No X-rays

X-rays generation is off in the following reasons:

- Sample chamber cover open, or not fully closed.

- Acquisition is completed.

X-ray Tube Related Problems

High Voltage breakdowns are identified by sudden changes in the HV and

tube current readings on monitoring in the software.

X-ray Tube Oil

Routinely check for oil leakage from the x-ray tube housing and inside chamber.

If a leak is noted, discontinue operation immediately and contact your service

engineer.

Warning:

The insulating oil is processed in the factory to attain high dielectric

strength. Please consult with the service agent before attempting to

add or replace the oil.

Loading...

Loading...