English - 32

003-2707-99

© Midmark Corporation 2015 TP202 20-42-FO-00014 Rev A1 C2169

A) With a cooled chamber, drain the sterilizer’s reservoir and refill with clean distilled water or water that

meets the referenced water purity specifications. Add one ounce of Speed-Clean sterilizer cleaner

directly to the bottom of chamber.

B) Run one Pouches cycle.

C) Press Stop button when Dry Cycle begins.

(Dry Cycle is not needed during maintenance.)

D) Drain reservoir and refill a second time with clean distilled water or water that meets the referenced

water purity specifications. .

E) Rinse by running one Unwrapped cycle

. Push the “Stop” button when the drying cycle

begins.

F) Drain and refill reservoir with clean distilled water or water that meets the referenced water purity

specifications, then allow sterilizer to cool.

G) Remove trays and tray rack. Wipe off with a damp cloth.

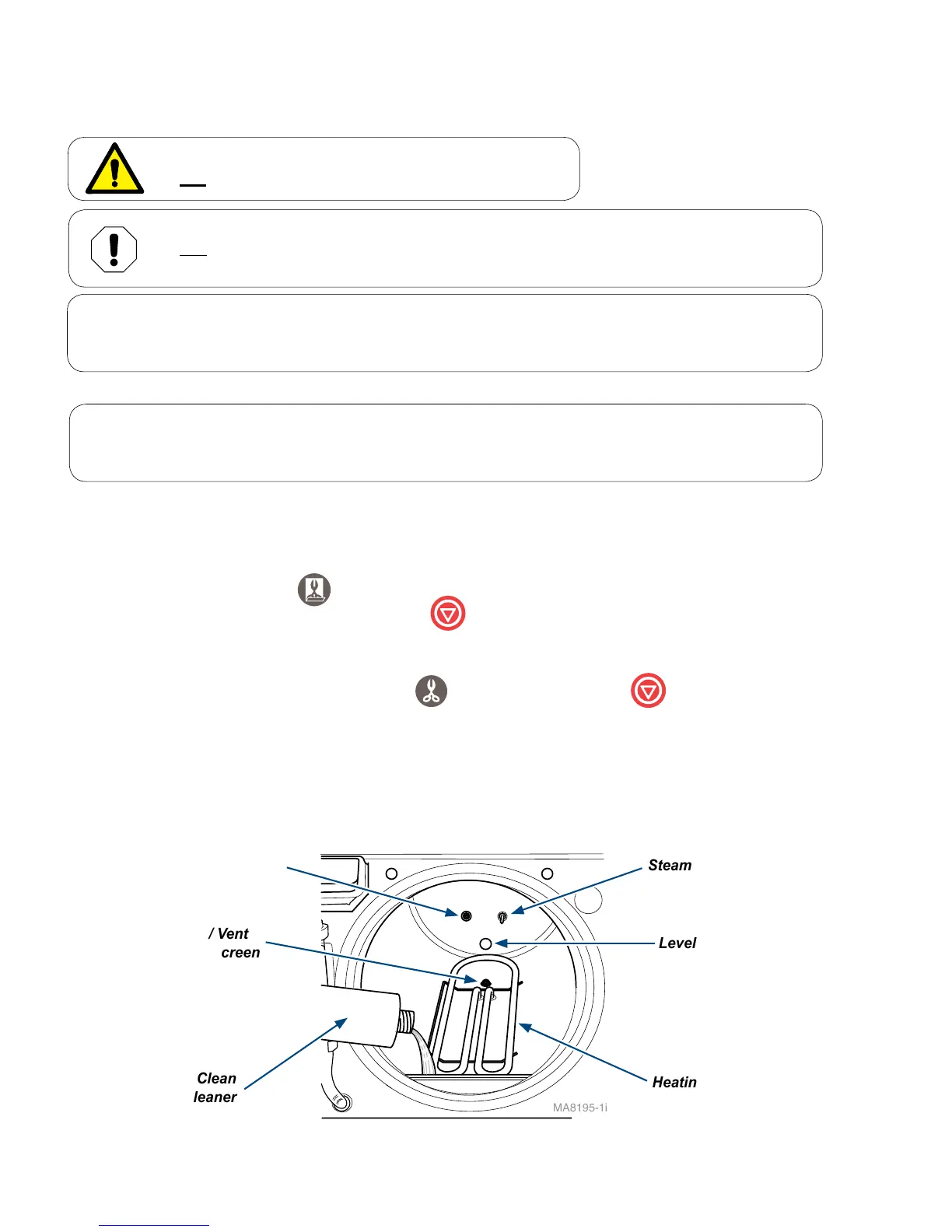

MA8195-1i

Fill / Vent

Filter Screen

Steam Temperature Probe

Level Sensor Probe

Heating Element

Speed-Clean

sterilizer cleaner

Air Filter Screen

Note

Steps A through G only need to be performed quarterly if the sterilizer is connected to a direct-to-

drain thermal reduction system.

WARNING

Do not process instruments while flushing system.

• Clean Chamber / Plumbing

Monthly Maintenance

Equipment Alert

Use only Speed-Clean to flush system. Failure to flush system with Speed-Clean may result in the

premature failure of sterilizer components.

Note

Every 28 days, the sterilizer will automatically display the PERFORM MONTHLY MAINTENANCE

message. If power is disconnected, the cycle of monthly messages will be reset.

Loading...

Loading...