5. START-UP AND OPERATION CHECKS

5.1. POSITIONING

The floor and/or supports on which the machine is positioned must be suitable for supporting the indicated weights.

Make sure enough space is left around the perimeter of the machine for using and carrying out maintenance on it

safely.

When choosing the machine position, please consider these points:

the machine size;

the operator's working areas, the space necessary for loading / unloading the trays and the space necessary

for accessing the control panel;

the movements necessary for cleaning the work station and the machine;

the space necessary for carrying out maintenance.

5.2. ELECTRICAL CONNECTION TO POWER SUPPLY AND EARTH

The Customer is always in charge of, and responsible for connecting the machine to the

electric power supply. The Customer is also responsible for power conductor protection and

creating a suitable and reliable earthing system.

The installing electrician must be specialised in work of this type. He/She must also be aware of all the technical

notions and regulations for working in a professional manner.

The machine must be connected to the electric power system of the installation premises in compliance with

standards (IEC-EN6 0204-I,IEC-EN 60349-I).

The power cable must be kept distant from parts that are hot, that can cut, or that move. It must also not obstruct

operator and material movements in the installation area.

Make sure the machine voltage indicated on the identification plate corresponds to the line voltage of the laboratory;

if it does not, DO NOT connect the machine to the power supply, instead contact the Retailer or Manufacturer

immediately.

The machine must be connected to an earthing system which must be prepared by the Customer in compliance

with what is indicated in current standards (LD 547/55 - IEC EN 60204-1 EN60445).

The connecting clamps are prepared inside the electric panel as specified in the attached wiring diagrams. Use the

statutory earthing system, not pipes for gas, water or other unspecified metal holders.

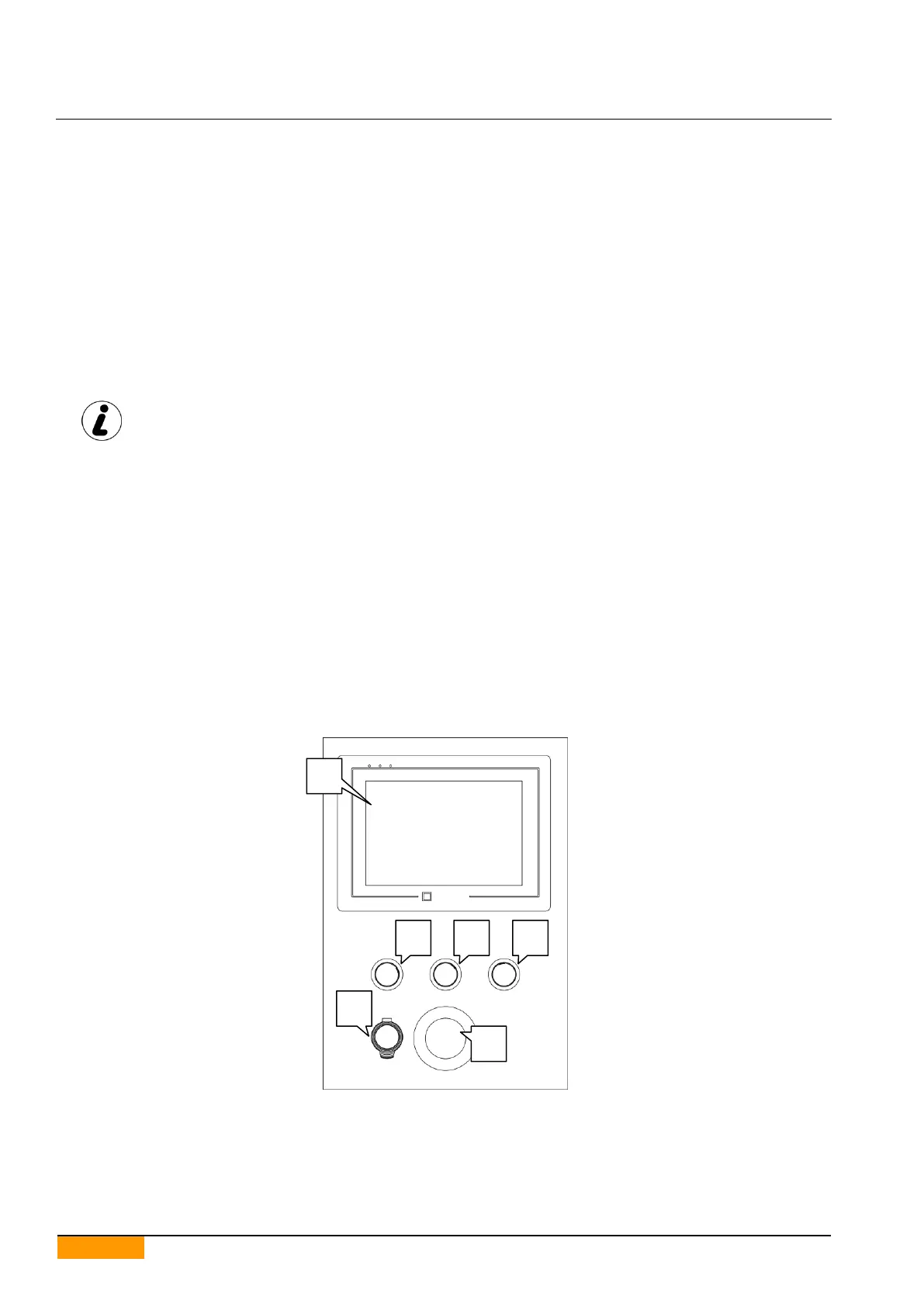

5.3. CONTROL DESCRIPTION

5.3.1. CONTROL PANEL

Operators have the control panel at their disposal, which can be used to carry out operations for setting up and

controlling the machine.

The operator has a stop push-button to stop the machine, in addition to an emergency stop push-button and safety

devices on the safety guards. Press the stop push-button to stop production temporarily. In danger situations, use

the emergency stop push-button to immediately stop the machine.

Loading...

Loading...