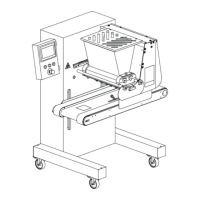

USE AND MAINTENANCE MANUAL

Causes, checks and possible solutions

Dropping inverter alarm

[error details]

A mechanical block has occurred.

An inverter malfunction has occurred.

There is no communication between the inverter and the PLC.

Make sure all the mechanical components can move freely.

Check the connection between the inverter and the PLC.

With the error description visible, consult the inverter instruction manual supplied with the

machine for more information.

Emergency button

pressed down

The emergency stop push-button has been pressed.

Release the emergency stop push-button.

Hopper safety guard

alarm

The guard is open or was not closed correctly.

The safety micro-switch is not operating correctly.

Close the guard.

Make sure there are no obstructions that prevent the guard from closing.

Check safety micro-switch operation and connection.

The cause of the inverter alarm state has not been found.

Make sure the connection between the inverter and the PLC is correct.

The rotary mould is not inserted correctly.

The mould is dirty.

The dough being used is too hard.

Make sure the rotary mould has been inserted correctly.

Clean the rotary mould thoroughly.

Soften the dough.

The machine is paused.

Press the start push-button to begin production.

Press the stop push-button to reset the work cycle.

The photocell beam has been interrupted.

The reflector is dirty or worn out.

The photocell is dirty or positioned incorrectly.

The photocell is worn out or positioned incorrectly.

Make sure there are no objects between the photocell and its reflector.

Clean or replace the reflector.

Clean the photocell.

Make sure the photocell and the reflector are aligned.

Check photocell operation and connection.

Push enabling push

button

The machine is waiting for the enabling push-button to be pressed.

The machine is waiting for the start push-button to be pressed.

Safety circuit malfunction

The cause that brought the machine to a halt in an emergency state has not been found.

Check guards, photocells and emergency stop push-button operation.

Slave module

communication timeout

One or more expansion modules has/have not been detected within the established lapsed

of time.

Make sure all the expansion modules are properly connected.

Table encoder malfunction

The PLC is not receiving any count from the encoder.

Check that the encoder operation is correct.

Make sure the connection between the PLC and the drive, or between the PLC and the

inverter, is correct.

Loading...

Loading...