IPB-5000A

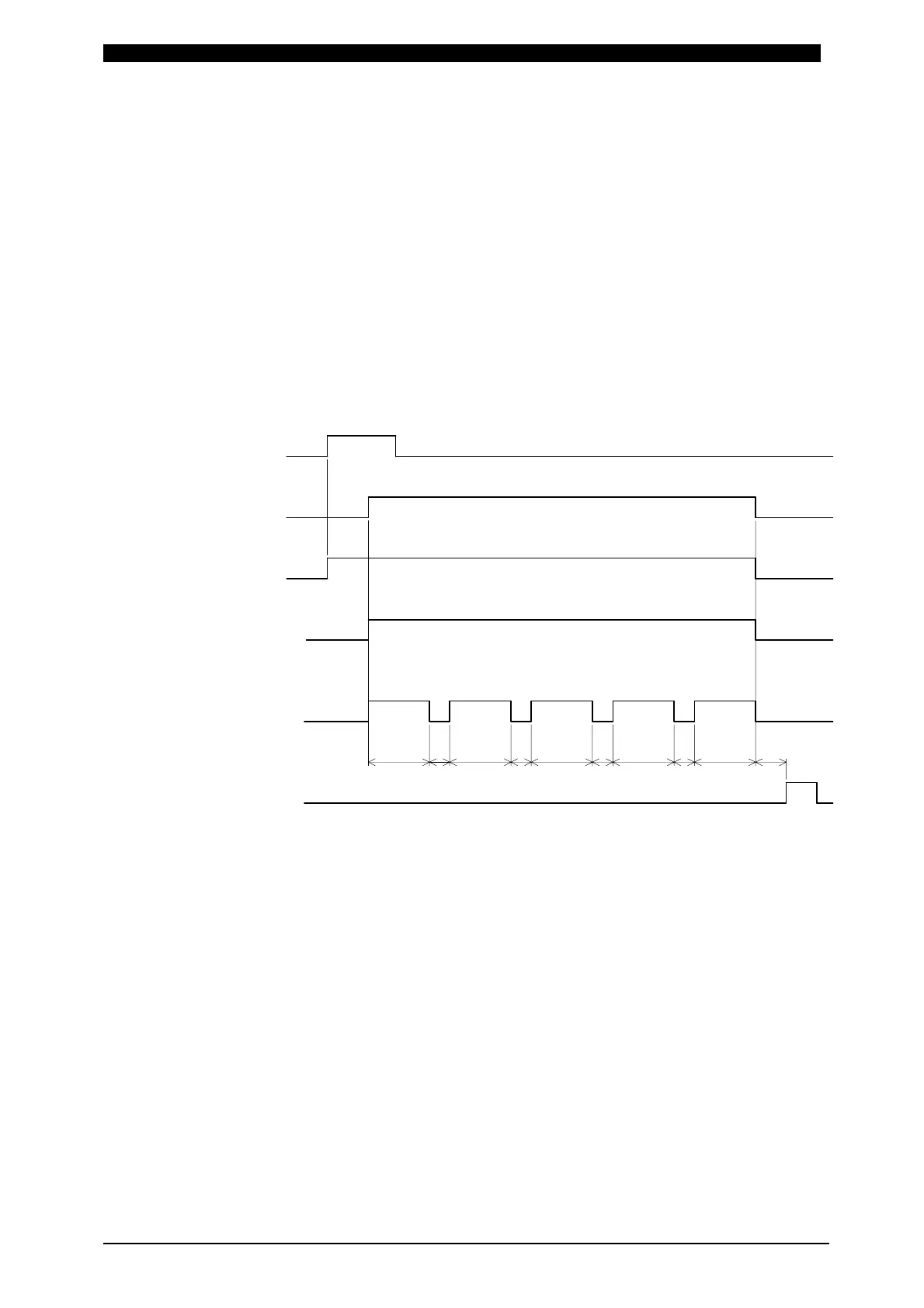

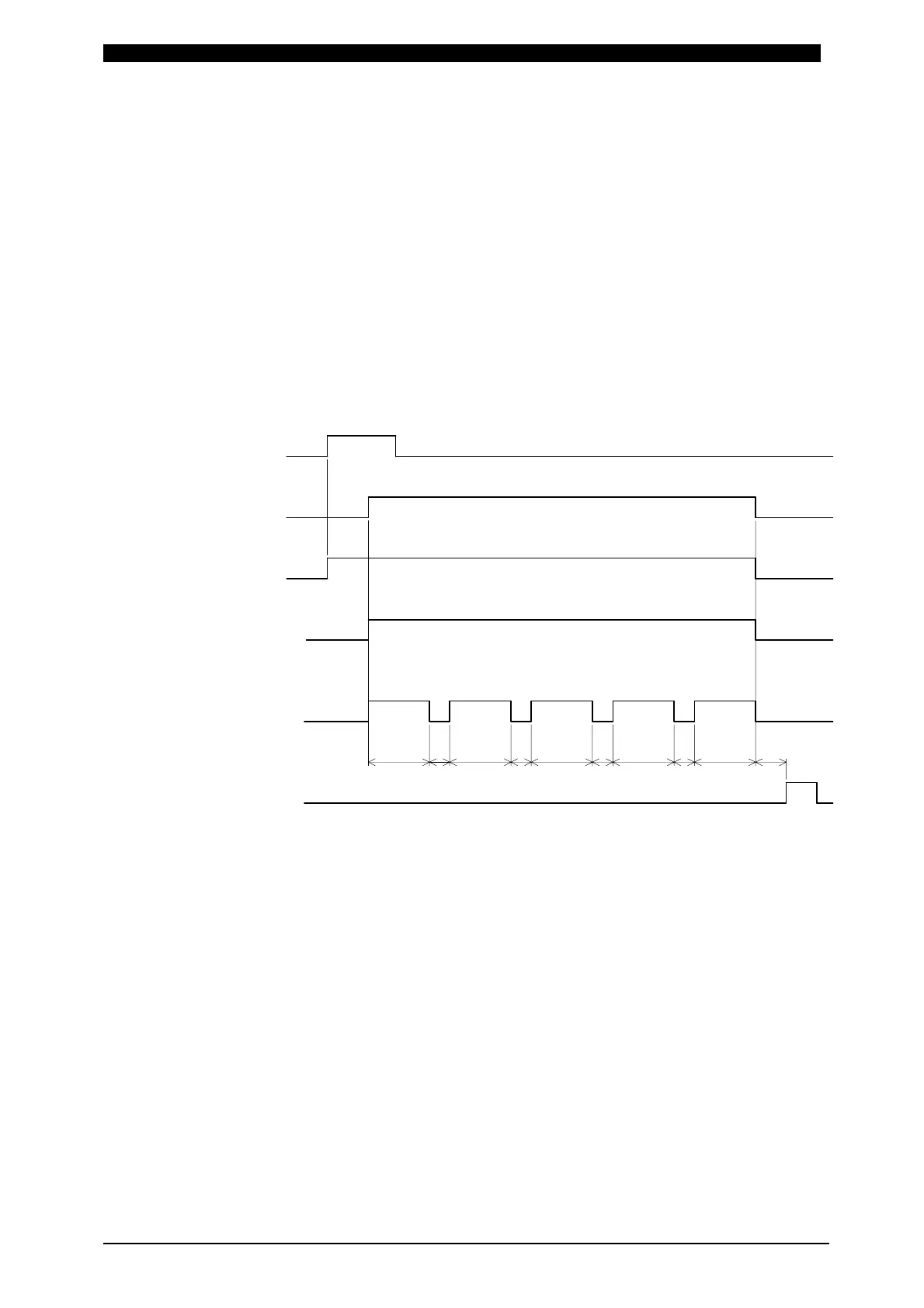

9. Time Chart

9-10

③ 1-5 Setting

Firstly, weld current is supplied on the first selected SCHEDULE No. and then

on the consecutive 5 SCHEDULE No.’s including the first selected No. in turn .

In this occasion, weld current is supplied through the transformer selected at

Transformer No. (TR#) in each SCHEDULE Screen.

That is to say, in the case that the supply of weld current is started in the

condition of SCHEDULE No.2 selected, firstly weld current is supplied on

SCHEDULE No.2, then SCHEDULE No.3, SCHEDULE No.4, SCHEDULE

No.5, lastly on SCHEDULE No.6.

For example, Supposing that SCHEDULE No. is 2 (SCH2) and Transformer No.

is 1 (TR#1), similarly SCH3-TR#4, SCH4-TR#5, SCH5-TR#2, SCH6-TR#3,

the time chart where the supply of weld current is started is shown as follows.

As Transformer 1 (TR#1) is set for the first SCHEDULE No.2 (SCH2), weld

current is firstly supplied through the transformer connected to Transformer 1

of Transformer Selector MA-650A, and then through Transformer 4,

Transformer 5, Transformer 2 and Transformer 3 in turn.

a: Monitored Value Computing Time and Transformer Changeover Time

It is the sum of b: Monitored Value Computing Time plus Transformer

Changeover Time, 10ms.

b: Monitored Value Computing Time

Changes in dependence on Monitor Value Calculation Mode

(CALCULATION MODE at 6.(9)①STATUS(1/2)Screen), Communication

Setting (COMM CONTROL and COMM SPEED at 6.(9)②STATUS(2/2)

Screen) and the type of screens as the following page.

END Output

Weld Current

SCH2

SOL2 output

SOL1 Output

2ND STAGE

1ST STAGE OFF

Transformer No.

TR#1

TR#4 TR#5 TR#2 TR#3

a

OFF

OFF

OFF

OFF

OFF

SCH3 SCH4

SCH5

SCH6

a

a

a

b

1-5 Setting in Transformer Selector

Loading...

Loading...