IPB-5000A

9. Time Chart

9-13

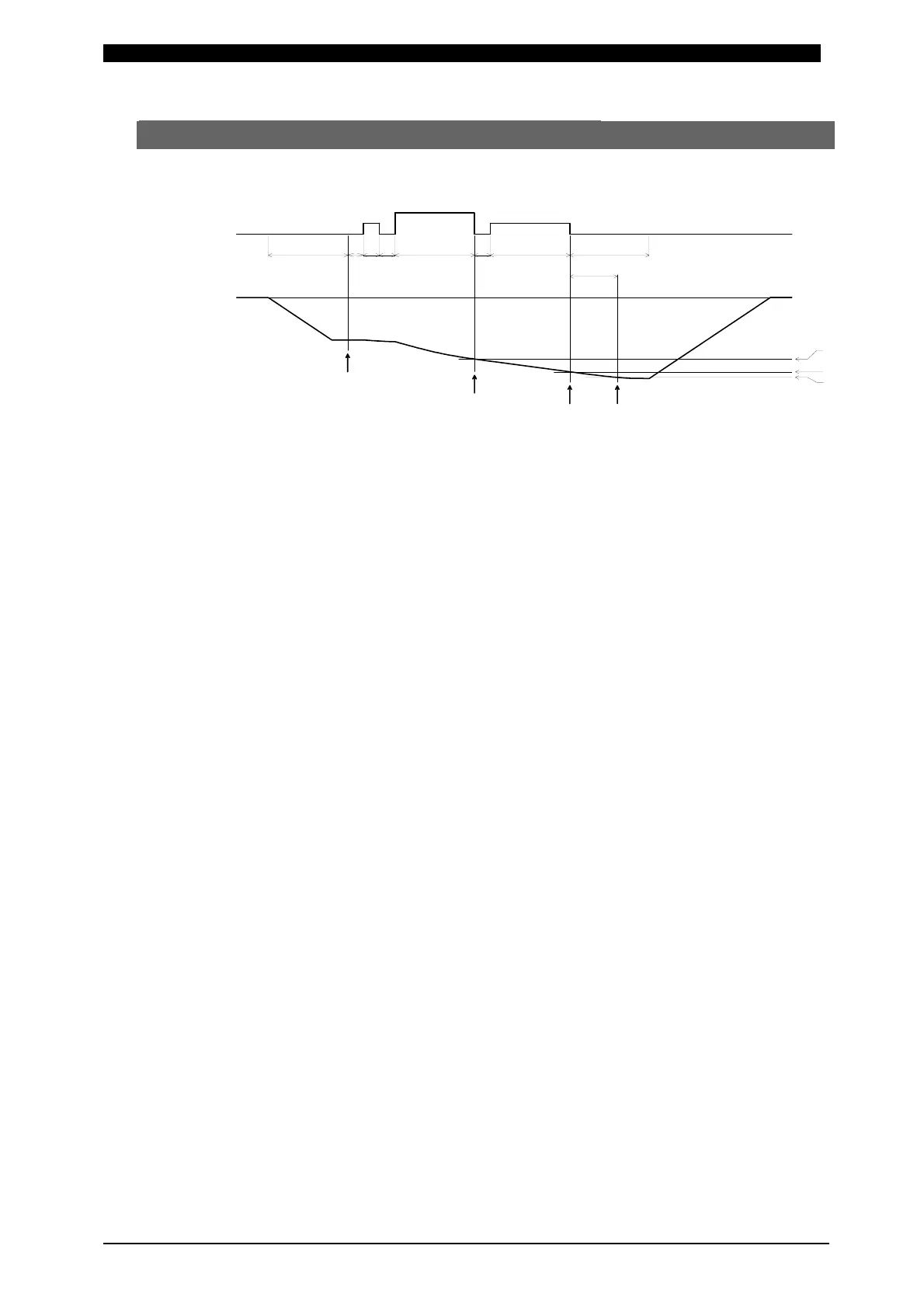

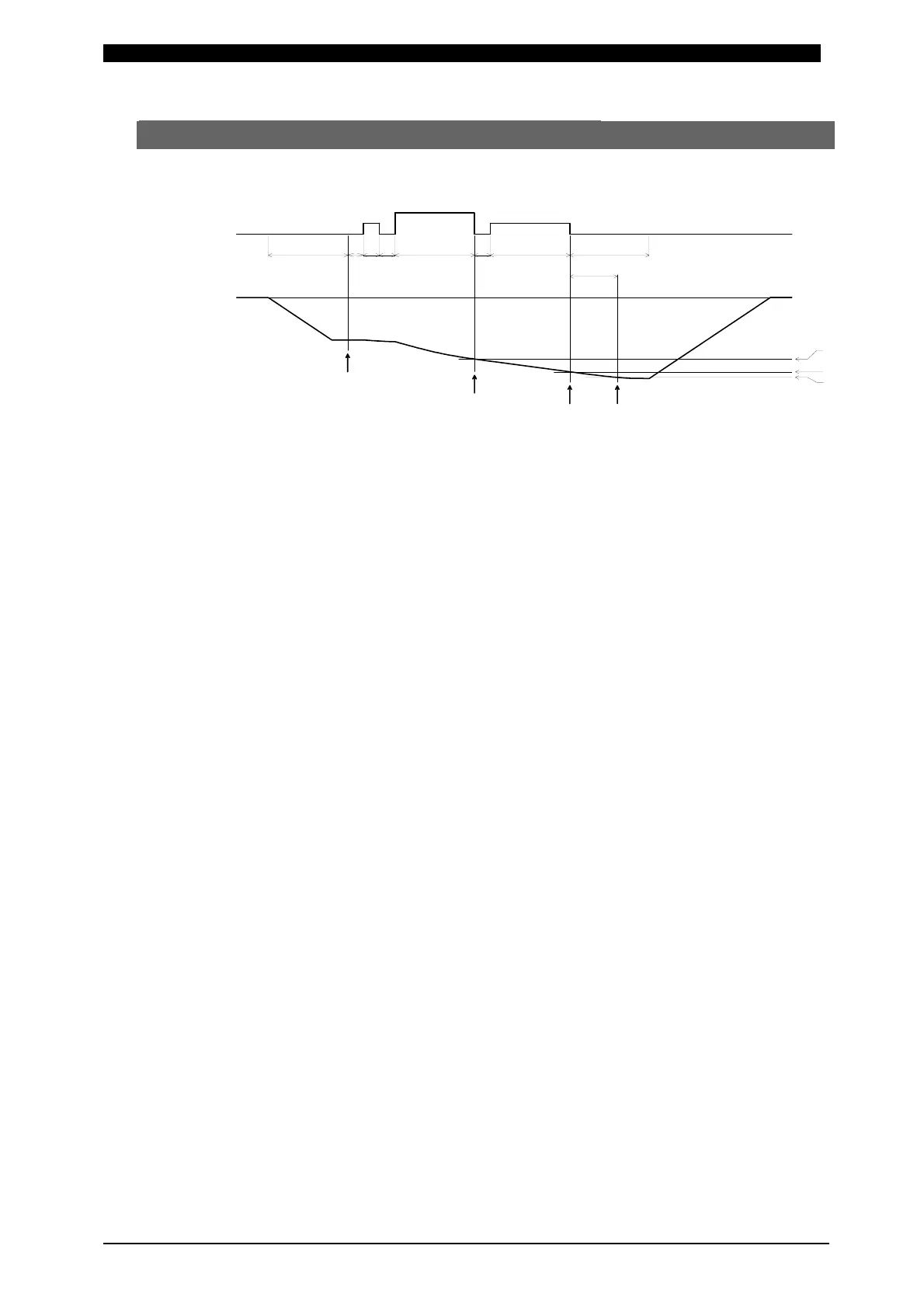

(9) Movement of Displacement Sensor

Symbol:

SQ: Squeeze Time WD: Work Detecting Time (0.4ms Max)

RC: Resistance Pre-check Time CP : Resistance Judgment Time (1ms)

W1: 1st Weld Time CO : Cool Time

W2: 2nd Weld Time HO : Hold Time

a: Work Detection

When the range of work detection is set to the work detection (WORK

DETECT at 6.(8)CONTROL Screen), the work detection is done after the end

of SQ. If the range of work detection is set to +/-00.00mm, no work detection is

done. Work detection Time is of 0.4ms Max.

b: 1st Weld Stop (W1)

When the displacement weld stop (DISPLC) is set to 1st Weld Stop to set the

displacement (WE1 DINPUT at 6.(8)CONTROL Screen) and the displacement

sensor arrives at the set displacement (e at the above figure), 1st Weld is

stopped to make the sequence move to the next cool time (CO).

c: 2nd Weld Stop (W2)

When the displacement weld stop (DISPLC) is set to 2nd Weld Stop to set

the displacement (WE1 DINPUT at 6.(8)CONTROL Screen) and the

displacement sensor arrives at the set displacement (f at the above figure),

2nd Weld is stopped to make the sequence move to the next hold time (HO).

d: Delay Time

When the value of Delay Time is set to DELAY TIME (DELAY TIME at

6.(8)CONTROL Screen), the displacement (g at the above figure) after the

delay time elapses is measured.

Displacement

g

f

e

dc

b

a

DELAY TIME

HOSQ W2W1 COWD CPRC

OFF

Weld

Current

Loading...

Loading...