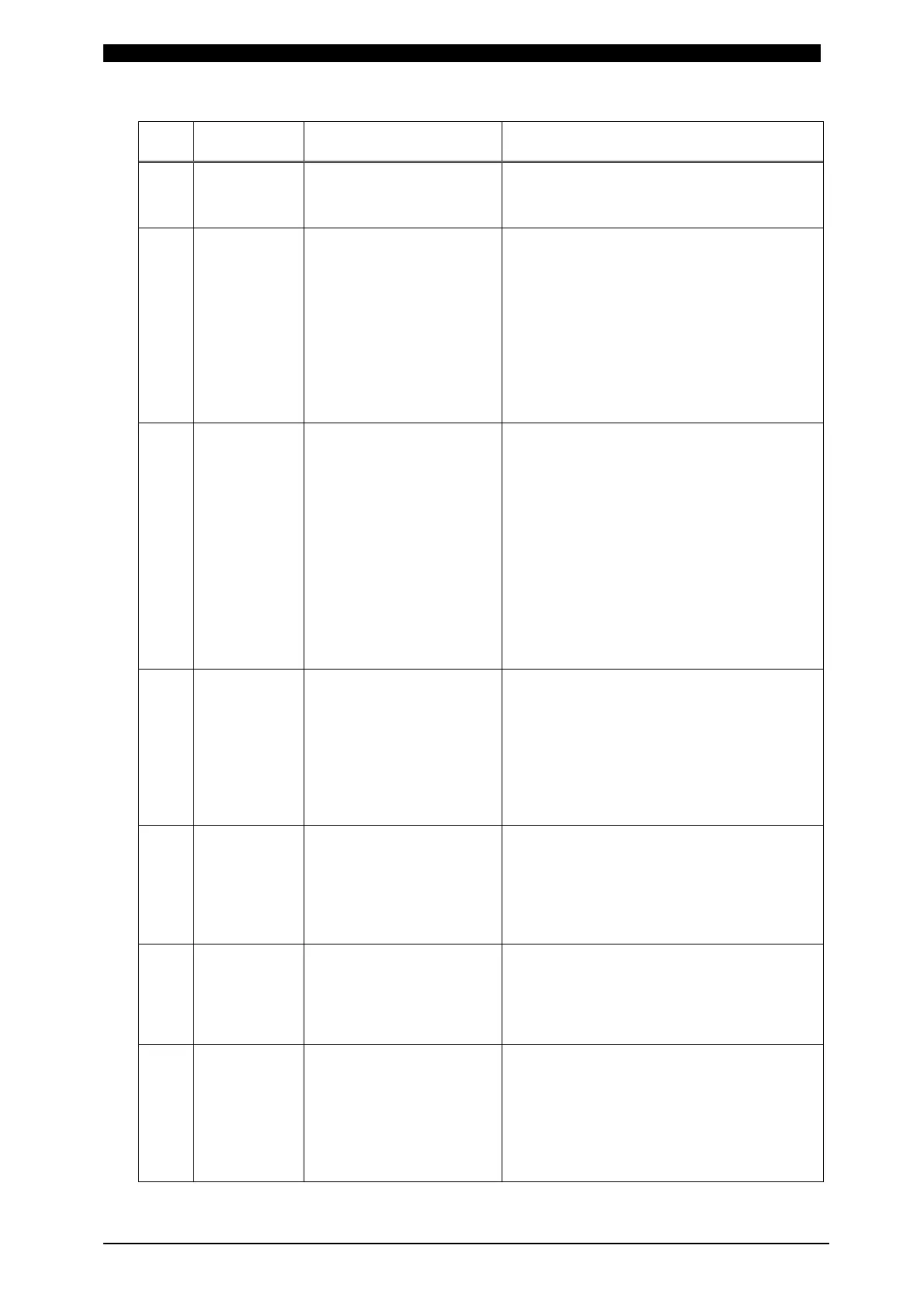

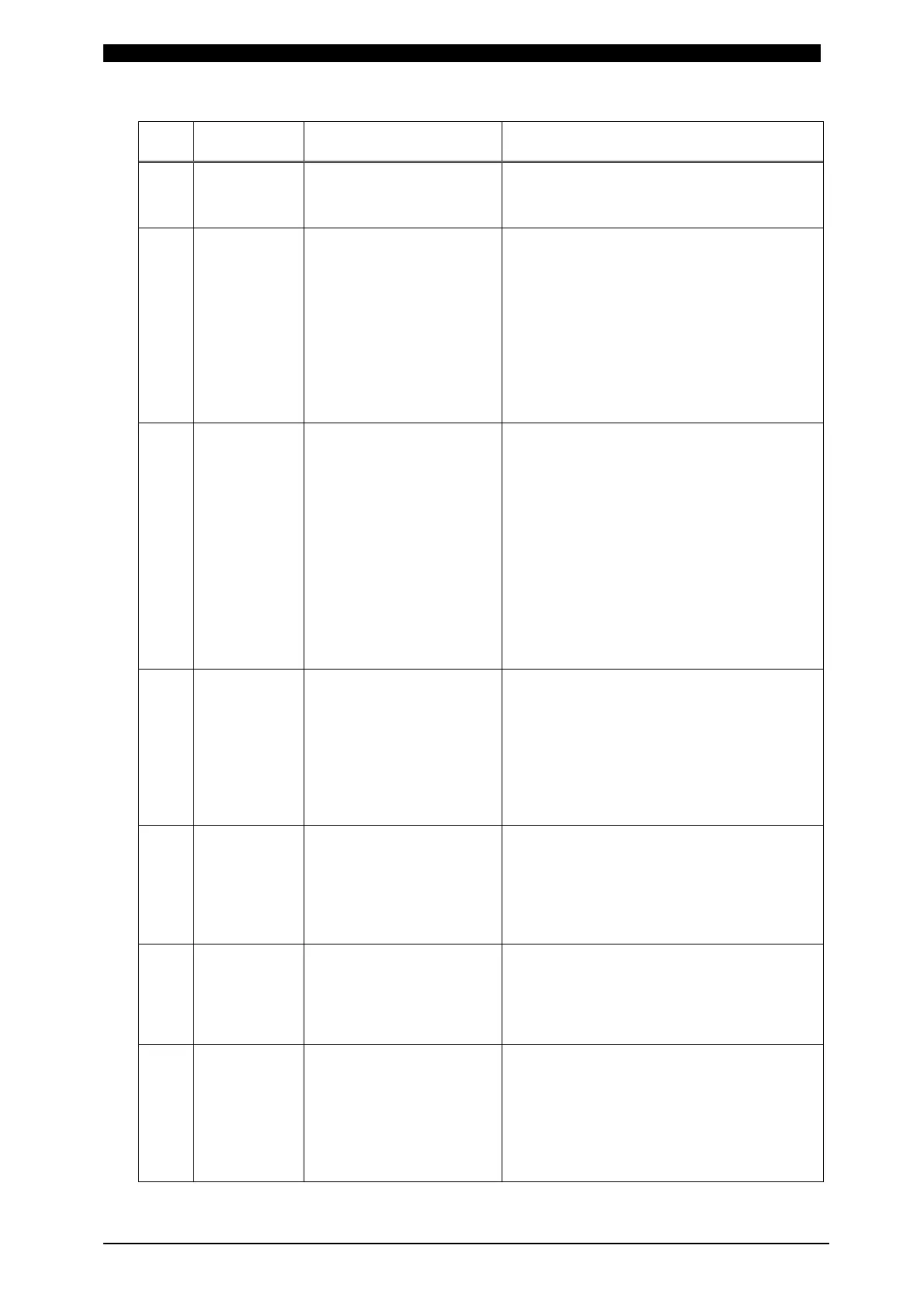

IPB-5000A

12. Error Codes

12-2

Error

Code

Contents Cause Corrective Action

E-07

ABORT

Short-circuit wire is cut

between Pin 1 and Pin 3

STOP on rear panel.

Connect Pin 1 to Pin 3 on rear terminal

strip.

E-08

NO

CURRENT

Weld current is not

flowing.

Or measured value of

weld current is 3% or

less of current range.

*Check the pressing force, electrode

contact and wire connection of weld

head.

*Check the setting of SQZ. Set longer

SQZ period than period of electrode

moving.

*At NO CURR MONITOR START in

STATUS Screen, start time of checking

“No Current” can be set. It is possible to

stop the detection of “No Current” at the

start of current flow by that setting.

E-09

NO

VOLTAGE

Voltage across

electrodes is 0.2V or

less.

Or voltage detecting

cable is not connected.

*Check connection and location of

voltage detecting cable.

*Check the pressing force, electrode

contact and wire connection of weld

head.

*At NO CURR MONITOR START in

STATUS Screen, start time of checking

“No Current” can be set. It is possible to

stop the detection of “No Current” at the

start of current flow by that setting.

This error does not happen when CURR

is set at CONTROL setting in STATUS

Screen.

E-11

PARITY

ERROR

Sum of numbers of

closed Schedule Select

Signal wires and a Parity

Signal wire is not odd.

Select and close Parity Signal so that the

sum of the numbers of closed Schedule

Select Signal wires and a Parity Signal

wire can be odd.

This error happens only when EXP. (P) is

set at SCHEDULE# setting and PARITY

is set at PARITY/WE1STOP setting in

STATUS Screen.

E-12

INTERRUPT

ERROR

Signals of Pin 20, W.

INTERRUPT and Pin 14,

PARITY(WE1STOP) at

terminal strip on rear

panel are closed at weld

starting.

Check input of W. INTERRUPT and

PARITY(WE1STOP).

E-13

CYCLE

ERROR

Pin 5, 2ND STAGE has

been open on rear panel

while weld sequence

operates.

Close Pin 5, 2ND STAGE until WE2 in

weld sequence goes to an end.

This error happens only when NO HOLD

is set at START SIG. HOLD setting in

STATUS Screen.

E-14

COUNT

MEMORY

ERROR

Count Data stored in

memory are damaged.

Memory was erased because period for

retaining memory of count data elapsed

over specified period.

The period for retaining the memory of

count data is approximately 10 days

since the day when a power supply is

turned off at latest.

Loading...

Loading...